Rockwell Automation 1746-BTM Barrel Temperature Control Module User Manual User Manual

Page 60

Publication 1746-UM010B-EN-P - April 2001

6-2 Monitoring Status Data

Values reported in words 12-15 for loops 1–4 vary, depending on the

bit code set in global commands N10:192/bits 08-10 and reported in

input image word N10:168/bits 08-10. You must interpret the reported

value according to the implied decimal point:

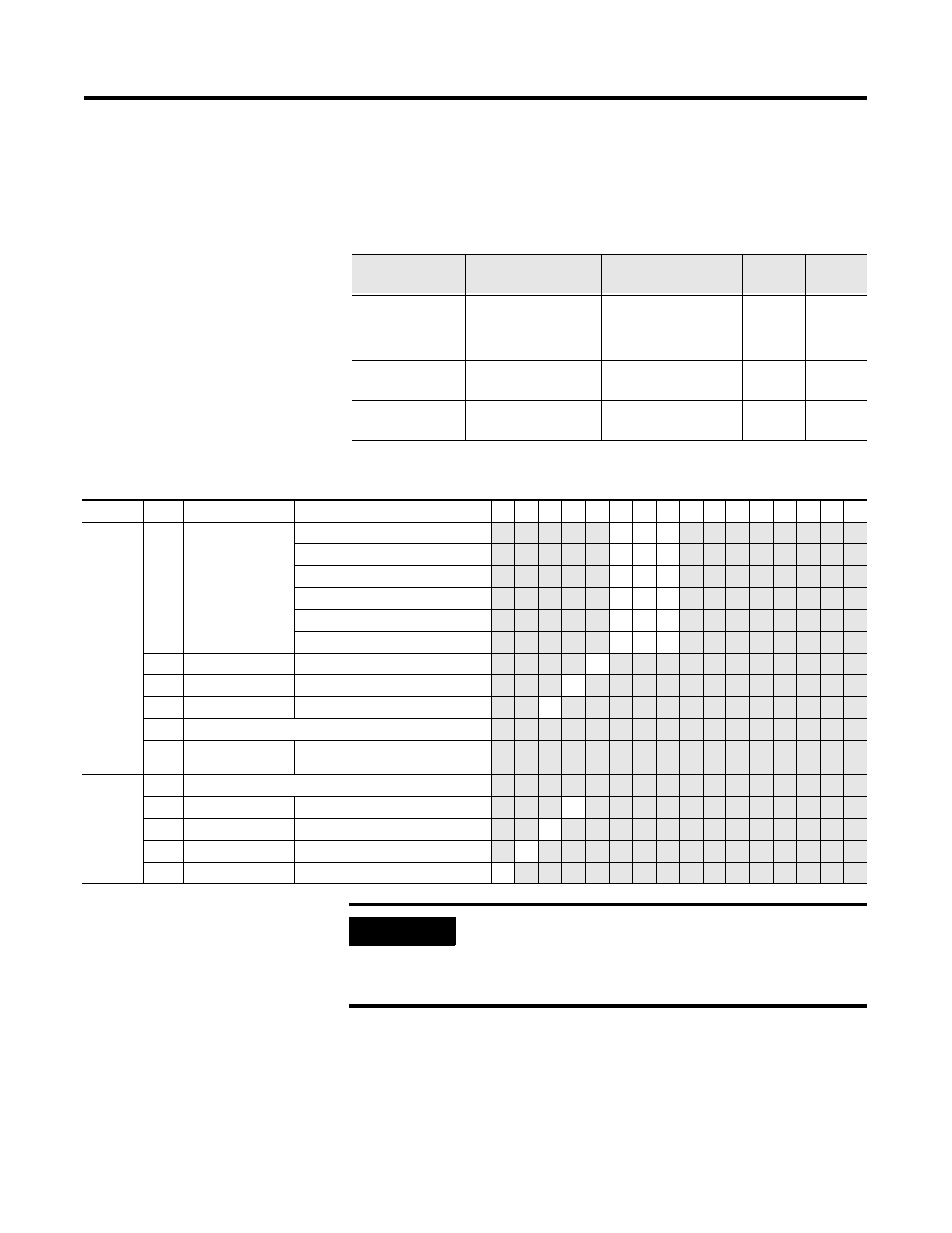

Table 6.C Global Status from All Loops

Remember that the module returns the control variable (CV) of each

loop to the input image table as both a numeric value (current CV)

and a time–proportioned output (TPO). For additional information,

Refer to BTM201.rss Data Table Layout on page 9-2 and

BTM50220.RSS Data table layout on page 9-7.

Table 6.B Interpret Implied Decimal Points

If N10:168/10-09-08

Reports:

Implied decimal point is:

Interpret

:

As:

0 0 1

0 1 0

1 0 1

current setpoint,

current error, or

cold–junction

temperature

1 decimal place

(from the right)

4999

499.9

0 1 1

current CV (analog

output)

2 decimal places

4999

49.99

1 0 0

1 1 0

error code, or

firmware revision number

none

4999

4999

Word

Bit

Define

Indicated By

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

8

upper

byte

8-10

Selection of Reported

values

See Important Below

Current setpoint

0

0

1

Current Error value

0

1

0

Current CV (loop output)

0

1

1

Current error code

1

0

0

Cold junction temperature

1

0

1

Firmware revision number

1

1

0

11

Autotune progress

0 = None; 1 = In progress

12

Cold junction low

0 = None; 1 = Alarm

13

Cold junction high

0 = None; 1 = Alarm

14

Reserved

15

Advanced rotator

values

0 = Normal Values

1 = Advanced Diagnostic Values

9

upper

byte

8-11

Reserved

12

M0 download

0 = None; 1 = Download

13

M1 download

0 = None; 1 = Download

14

M0 upload

0 = No; 1 = Upload

15

M1 upload

0 = No; 1 = Upload

IMPORTANT

The sample program returns all six variables. For

their data table locations, Refer to BTM201.rss Data

Table Layout on page 9-2 and BTM50220.RSS Data

table layout on page 9-7.