Barrel/non-barrel control, Word 1, bit 12 for channel 1, Barrel control – Rockwell Automation 1746-BTM Barrel Temperature Control Module User Manual User Manual

Page 29: Non–barrel control, Switching the barrel control, Barrel/non-barrel control -3

Publication 1746-UM010B-EN-P - April 2001

Configuring the Module 3-3

Barrel/Non-barrel Control

Word 1, Bit 12 for Channel 1

You select between barrel and non–barrel control.

Barrel Control

Select barrel control for multiple–zone applications in which there is

thermal conduction between the zones. Injection molding and

extrusion are good example applications because they use multiple

heater bands (zones) mounted on one thermal conductor (the metal

barrel). The barrel conducts heat between different zones. If you

select barrel control, also select between inner and outer zones (word

1, bit 13 for channel 1). A barrel loop is autotuned as the temperature

rises from a cold start to a temperature setpoint during startup.

Non–barrel control

Select non–barrel control for applications with independent loops and

no thermal conduction between zones. If you select non–barrel

control, the inner/outer zone selection doesn’t apply.

Switching the barrel control

For some applications, even though the loops are independent with

no thermal conduction between zones, barrel control might provide

better performance than non–barrel control. If a loop has any of these

characteristics, you might want to use barrel control if the:

•

time constant is greater than 10 - 30 seconds

•

loop has a problem of overshooting the setpoint

•

loop output is saturating (CV is at 100%) for a significant

duration

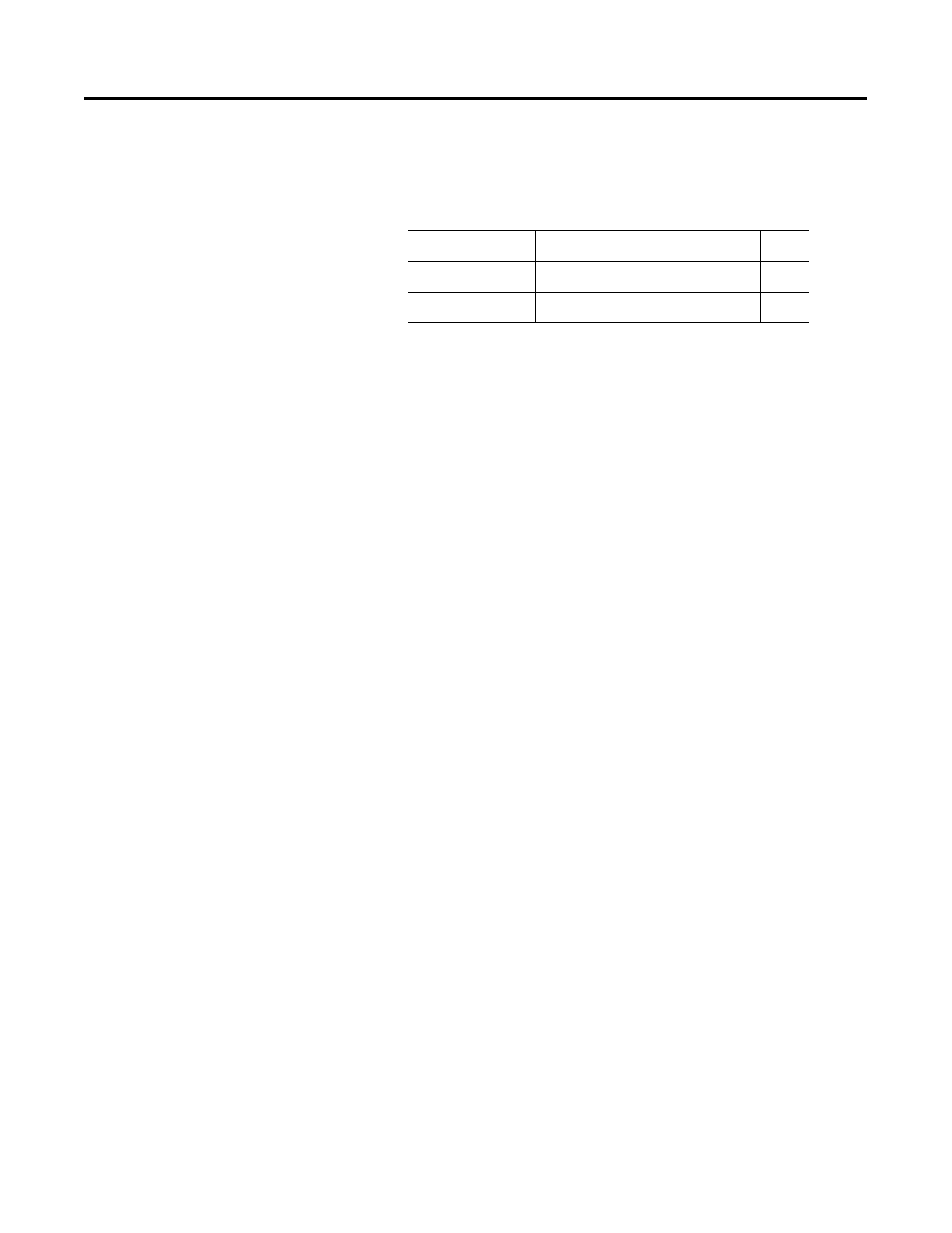

Select:

for these applications:

12

barrel control

heat–only or heat/cool

0

non–barrel control

heat–only, cool–only, or heat/cool

1