Rockwell Automation 22C PowerFlex 400 AC Drive Quick Start - FRN 1-4.xx User Manual

Page 8

English-8

PowerFlex 400 Adjustable Frequency AC Drive Quick Start

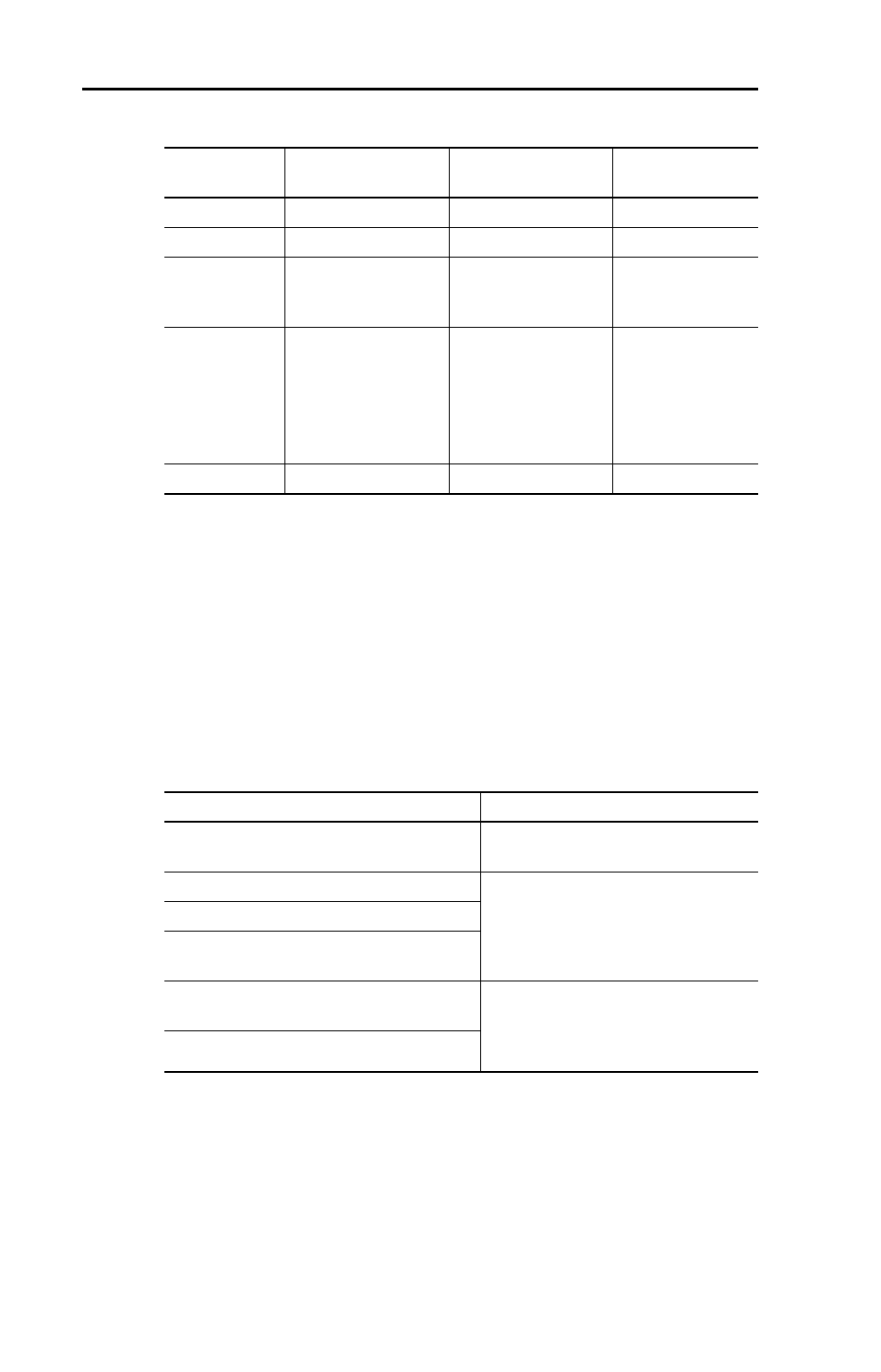

Power Terminal Block Specifications

Important: Frame C, D, and F drives utilize a finger guard over the

power wiring terminals. Replace the finger guard when

wiring is complete.

Refer to the PowerFlex 400 User Manual for maximum power cable

length recommendations.

Input Power Conditions

Frame

Maximum Wire Size

(1)

(1)

Maximum/minimum sizes that the terminal block will accept - these are not

recommendations. If national or local codes require sizes outside this range, lugs may

be used.

Minimum Wire Size

(1)

Recommended

Torque

C

8.4 mm

2

(8 AWG)

1.3 mm

2

(16 AWG)

2.9 N-m (26 lb.-in.)

D

33.6 mm

2

(2 AWG)

8.4 mm

2

(8 AWG)

5.1 N-m (45 lb.-in.)

E

480V

37-45 kW

(50-60 HP)

33.6 mm

2

(2 AWG)

3.5 mm

2

(12 AWG)

5.6 N-m (49.5 lb.-in.)

E

240V

30-37 kW

(40-50 HP)

480V

55-75 kW

(75-100 HP)

107.2 mm

2

(4/0 AWG)

53.5 mm

2

(1/0 AWG)

19.5 N-m (173 lb.-in.)

F

152.5 mm

2

(300 MCM) 85.0 mm

2

(3/0 AWG)

19.5 N-m (173 lb.-in.)

Input Power Condition

Corrective Action

Low Line Impedance (less than 1% line

reactance)

•

Install Line Reactor

(1)

•

or Isolation Transformer

(1)

Refer to the PowerFlex 400 User Manual for accessory ordering information.

Line has power factor correction capacitors

•

Install Line Reactor

•

or Isolation Transformer

Line has frequent power interruptions

Line has intermittent noise spikes in excess of

6000V (lightning)

Phase to ground voltage exceeds 125% of

normal line to line voltage

•

Remove MOV jumper to ground

(Frame C, E & F drives only)

•

or Install Isolation Transformer with

grounded secondary if necessary

Ungrounded distribution system