Usg drywall suspension system – USG Exterior Ceiling Applications Systems Guide User Manual

Page 39

38 USG Exterior Ceiling Applications

USG Drywall Suspension System

Test Record UL526E

Class 90 Uplift

System Components

Main runners

DGL26 or DGLW26

Cross Tees

DGL424 or DGLW424

Perimeter Molding

DGWM24 angle mold or DGCM27 channel mold.

When angle mold is used, main runners and cross tees attached to molding with 1/29 type S screws.

Gypsum Panels

– Two layers of 5/8 in. thick, 4 ft wide gypsum board. Inner layer installed with long dimension perpendicular to

cross tees. End joints centered along cross tees. Side joints centered along main runners.

– Gypsum board fastened to each cross tee with no. 8, 1 in. long bugle head screws with one screw located at

midspan of cross tee and with additional screws spaced 12 in. o.c. beginning from center screw with screws

located 1-1/2 in. from gypsum board side joint. At butt ends, a total of seven screws used with one screw

located at midspan of cross tee and additional screws spaced 8 in. o.c. with one screw located 1-1/2 in. from

side joints. All screws located 1/2 in. from edge.

– End joints of adjacent sheets staggered min 4ft.

– Outer layer rotated 90 degree from inner layer and attached to cross tees and main runners through inner

layer using 1-5/8 in. long screws spaced 8 in. o.c. at butt ends. and 12 in. o.c. in the field. (Same spacing as

inner layer).

– Butt joints centered along main runners and staggered min 4 ft. Gypsum board attached to lower leg of wall

channel with fasteners spaced 12 in. o.c. for both layers.

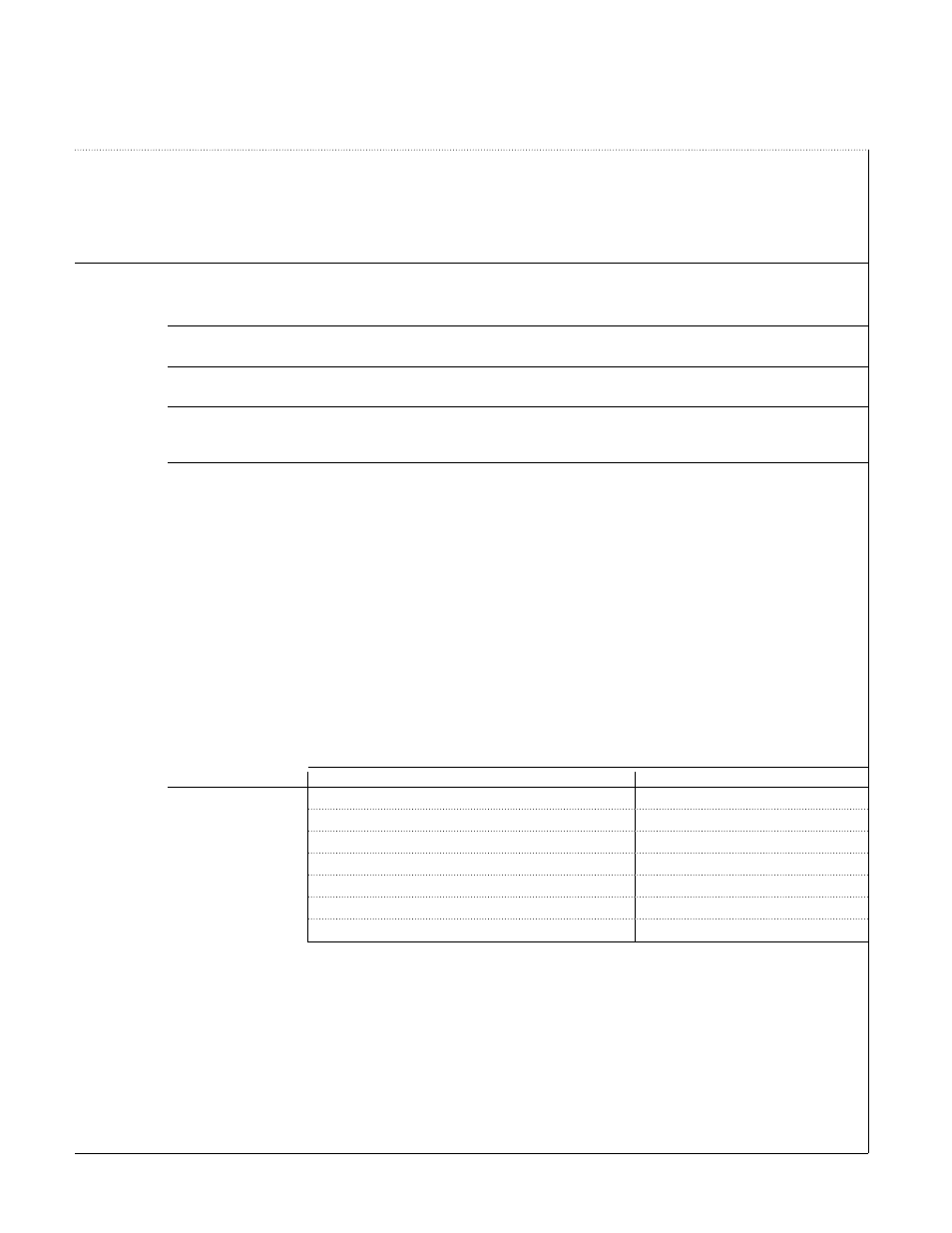

Type

Max Unbraced Length (in)

Compression Posts

3/49 x 1/29 x 0.0599 channel

28

3/49 x 1/29 x 0.0599 channel (Back-to-back)

46

1-1/29 x 7/329 x 0.0599 channel

31

1-1/29 x 7/329 x 0.0599 channel (Back-to-back)

41

3/49 EMT conduit, 0.049” wall thickness

59

1-5/89 25 gauge steel studs, 0.01799 min

61

1-5/89 25 gauge steel studs, 0.01799 min (Back-to-back)

76

–

Back to back types shall be connected with stitch welds at 129 OC or with 1/49 dia bolts at 129 OC,

first connection within 69 of each end.

–

Compression posts to be located within 69 of expansion joints if applicable.

– All compression post notched at ends to fit over bulb of main runner.

– Compression post fastened to main runners with type S coated steel screw or equivalent

– 33 ksi min steel.