MacDon R85 Rotary Disc 13 Foot Pull-Type User Manual

Page 94

MAINTENANCE AND SERVICING

Form 169454

92

Revision A

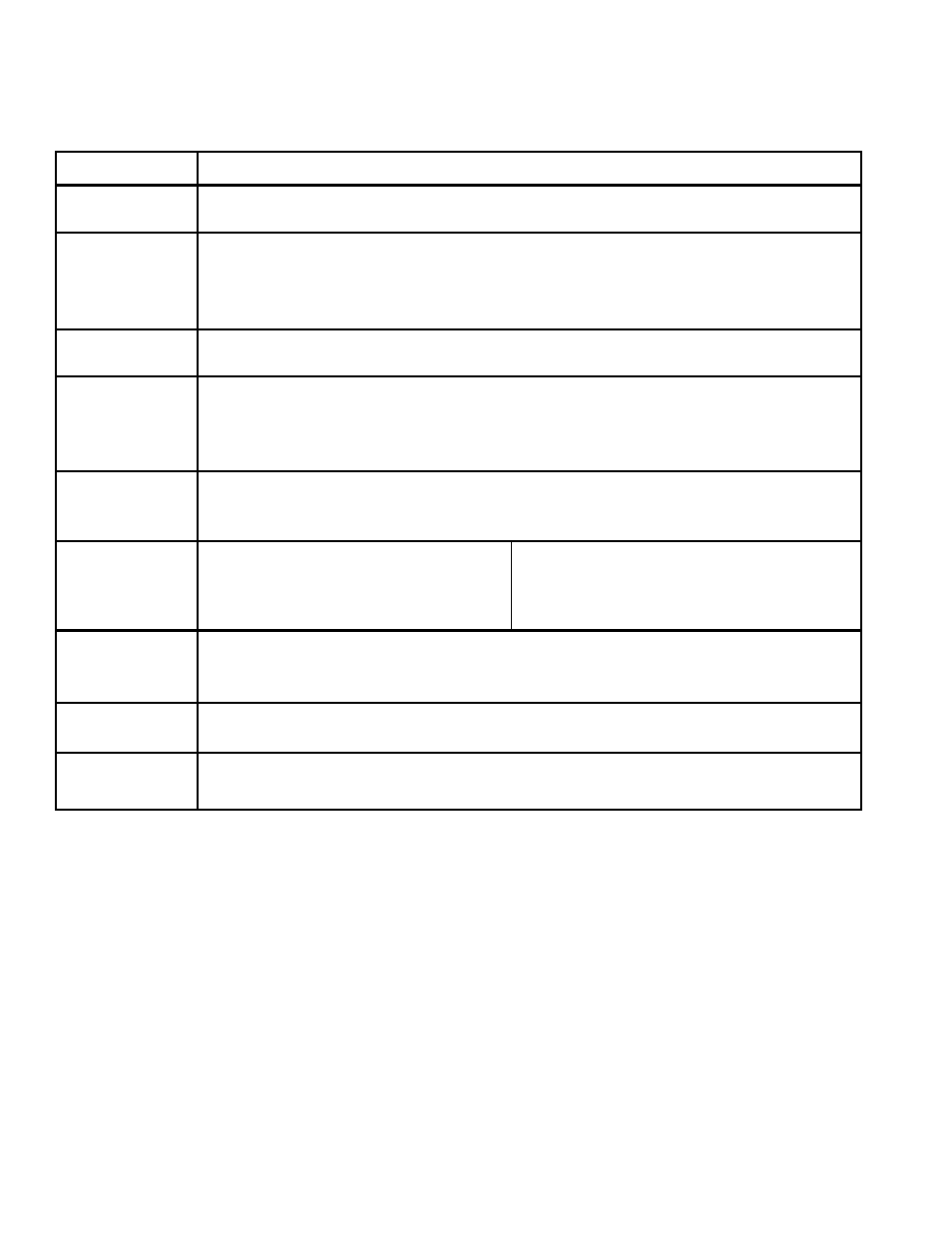

7.13.2 Interval Maintenance

INTERVAL SERVICE

FIRST USE

Refer To Section 7.13.1 Break-In Inspections

(previous page)

100 HOURS OR

ANNUALLY *

1. Check Bevel Gearbox Lubricant Level.

2. Check Wheel Bolt Torque.

3. Check Conditioner Drive Belt Tension.

4. Grease Wheel Hub Bearings.

END OF

SEASON

Refer To Section 6.16 STORAGE

10 HOURS OR

DAILY

1. Check Hydraulic Oil Level.

2. Check Hydraulic Hoses and Lines For Leaks.

3. Check Rotary Deflectors, Cutter Blades, and Discs For Security and Condition.

4. Check Tire Pressure.

25 HOURS

1. Grease Cutterbar Driveline Bearings.

2. Grease Roll Universal Shafts.

3. Grease PTO Shaft and Universals.

50 HOURS

1. Grease

APT

Pivot.

2. Grease Steering Cylinder Pivot

3. Grease Drive Belt Tensioner.

4. Grease APT Hitch Swivel.

5. Grease Roll Shaft Bearings.

6. Grease Lift Cylinder Pivot.

7. Grease Lower Link Pivots.

250 HOURS

1. Change Hydraulic Oil Filter.

2. Change

Cutterbar

Lubricant.

3. Change Bevel Gearbox Lubricant.

500 HOURS OR

3 YEARS

1. Change

Hydraulic

Oil.

1000 HOURS OR

3 YEARS

1. Change Pump Gearbox Oil.

* IT IS RECOMMENDED THAT ANNUAL MAINTENANCE BE DONE PRIOR TO START OF OPERATING

SEASON.