Warning – MacDon A40-D Pull-Type User Manual

Page 87

SECTION 6 OPERATION

169000

85

Revision F

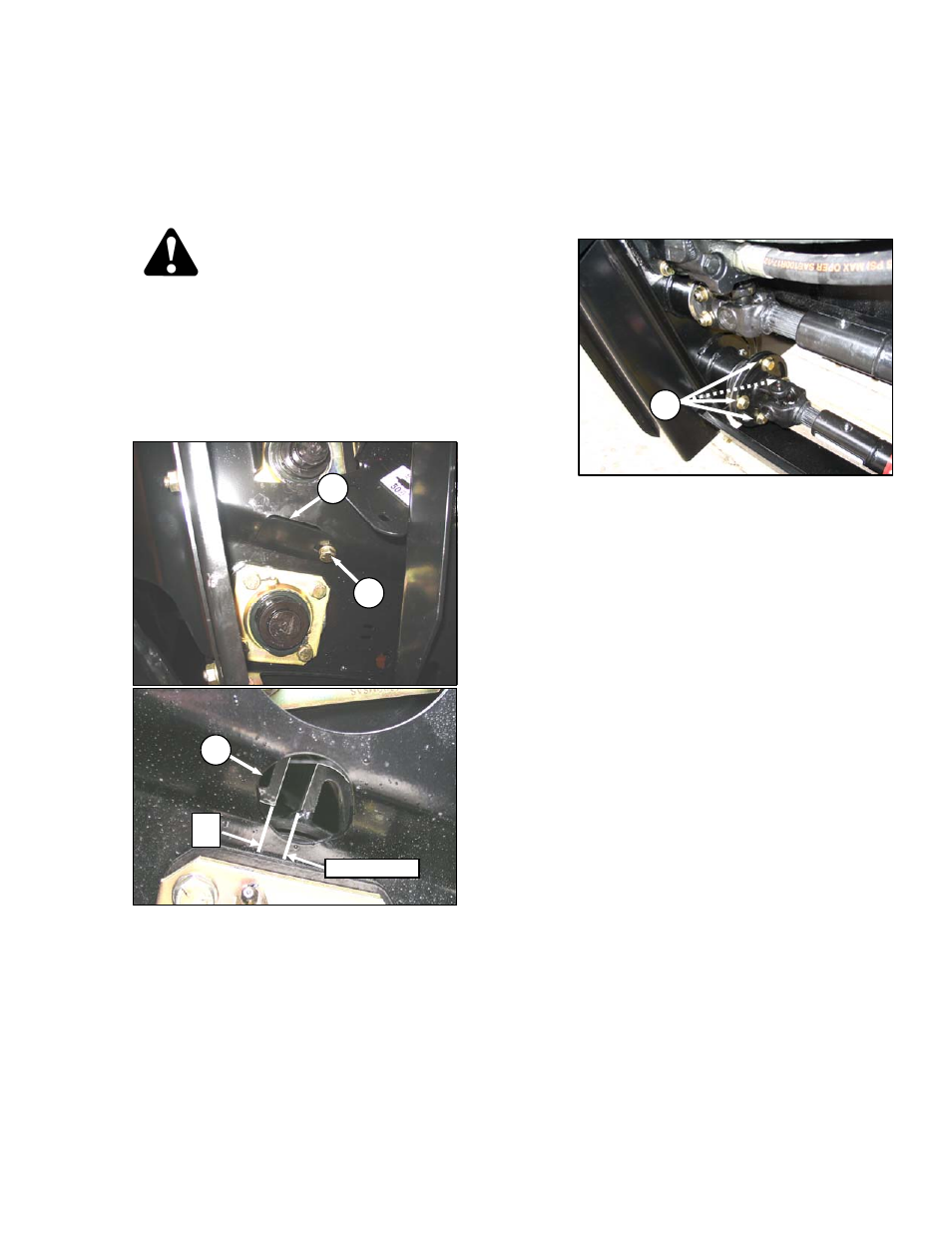

6.17.12.2 Roll Timing and Alignment

For proper conditioning, the rolls must be

properly timed and aligned, with each steel bar

on one roll centered between two bars of the

other roll as shown. The factory-setting should

be suitable for most crop conditions.

WARNING

To avoid bodily injury or death from

unexpected start-up or fall of raised

machine; stop engine, remove key, and

engage lift cylinder stops before going under

machine to examine roll timing, or for

any reason.

6.17.12.2.1 Roll

Timing

a. Loosen bolt (A), and rotate cover (B) to expose

access port (C) at each end of conditioner.

b. Examine roll timing (distance ‘X’) at each end of

the rolls with header fully lowered. Each steel

bar on one roll should be centered between two

bars of the other roll so that distance ‘X’ is

0.5 in. (12 mm).

NOTE

If the distance ‘X’ varies more than

1/16 in. (1.6 mm) from one end to the

other, the rolls should be re-aligned.

Refer to next Section 6.17.12.2.2

Roll Alignment.

c. If required, adjust the roll timing as follows:

1. Loosen four bolts (D) in slots of yoke plate

on lower roll universal shaft.

2. Turn rolls to achieve best timing.

3. When roll timing is satisfactory, tighten

bolts (D) to secure the position.

4. Recheck distance between the bars at both

ends of the rolls at (C).

5. Close cover (B), and tighten bolt (A).

D

A

B

0.5 in. (12 mm)

C

X