Caution – MacDon A40-D Pull-Type User Manual

Page 65

SECTION 6 OPERATION

169000

63

Revision F

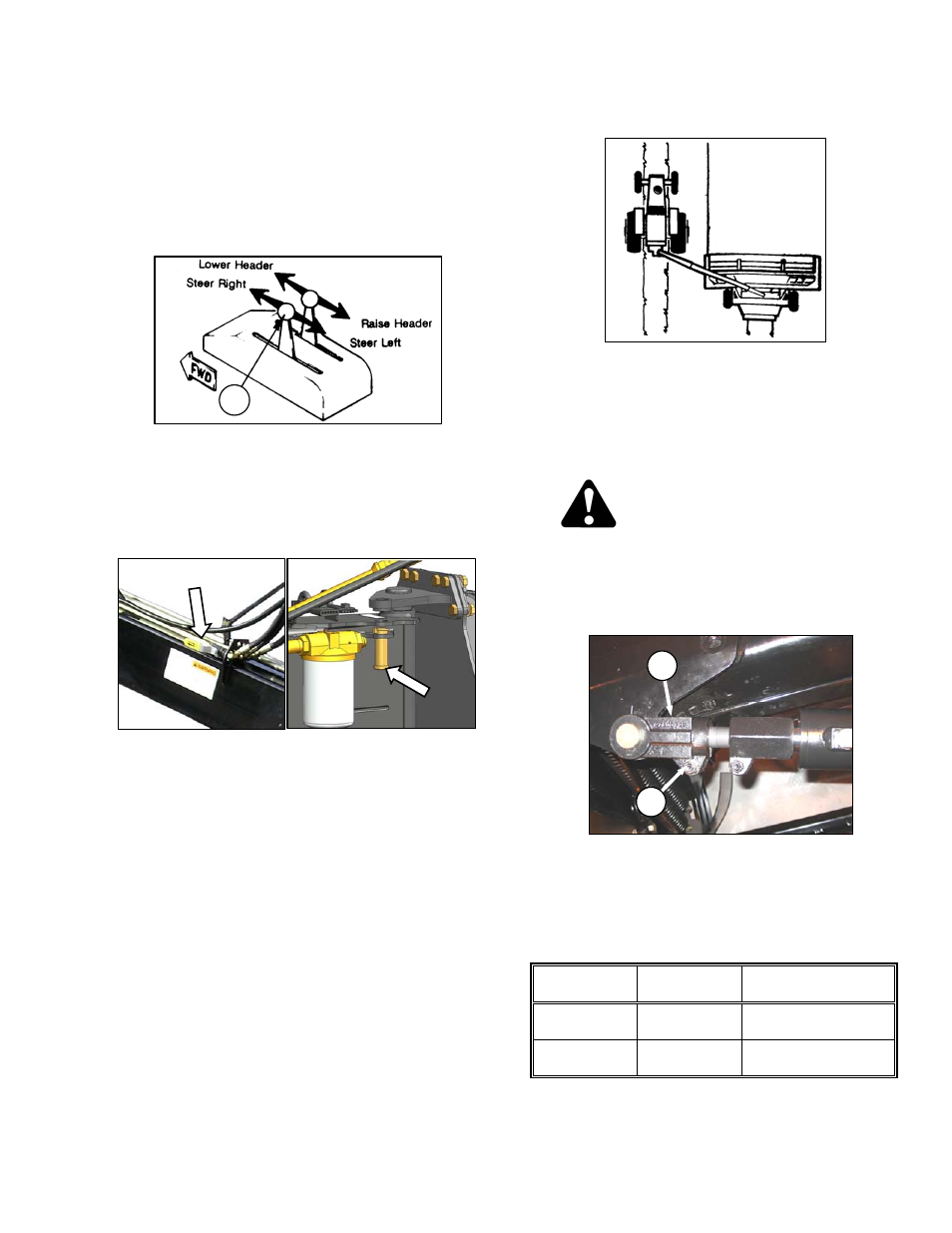

6.15 STEERING:

PULL-TYPE

Steering the mower conditioner is controlled by

the tractor’s remote hydraulic system. This

steering system allows the mower conditioner to

follow directly behind the tractor, make a full cut

to either side, or any position in-between.

IMPORTANT

Hoses should be connected so that

moving tractor control lever (A)

FORWARD steers machine to the RIGHT,

and moving lever (A) BACKWARD steers

machine LEFT.

IMPORTANT

To allow Articulating Power Tongue (APT)

to swing, the valve on the APT must be in

the working or open position (handle

in-line with APT), and the temporary

transport lock pin must be in the

storage location.

The center pivot provides the Operator the

opportunity to:

• easily move the mower conditioner into the

field position,

• make right angle turns in either direction,

• steer around objects on both sides, and

• perform straight line field cutting on either

side of the tractor.

The control is operated momentarily for

steering, and MUST be returned to OFF or

NEUTRAL position as soon as the mower

conditioner reaches the desired path of travel.

6.15.1 Right Side Operation: Pull-Type

Move steering lever FORWARD to achieve

desired position of mower conditioner on RIGHT

side of tractor.

To adjust tracking of mower conditioner during

right side operation, the steering cylinder clevis

can be re-positioned:

CAUTION

Stop engine, and remove key from ignition

before leaving Operator's seat for any

reason. A child or even a pet could engage

an idling machine.

a. Shut down tractor, and remove key.

b. Loosen clamping bolt (B) on clevis (C).

c. Using a wrench on the stroke control (B), rotate

cylinder rod so that clevis moves away from or

closer to the cylinder. Each turn of the rod

changes the tracking by approximately

2 in. (50 mm).

DESIRED

TRACK

CYLINDER

EXTENSION

CLEVIS POSITION

Further RIGHT

Increase

Clevis (C) Further

From Cylinder

Further LEFT

Decrease

Clevis (C) Closer

To Cylinder

d. Tighten clamping bolt to 65 ft·lbf (90 N·m).

e. Recheck torque on clamping bolt after 1 hour,

and every 100 hours thereafter.

A

B

C