Caution, Warning – MacDon A40-D Pull-Type User Manual

Page 151

SECTION 7 MAINTENANCE AND SERVICING

169000

149

Revision F

7.11.3 Auger Pans

The high density polyethylene auger pans are

repairable and replaceable. Refer to the

technical manual, MD Part #169048 for details

on replacing the pans.

IMPORTANT

To prolong the life of the auger pan, be

sure to check that reel tines do NOT

contact the pans when adjusting the reel

position or tine pitch.

Stones and other debris can deform the

polyethylene pans. If this occurs, the pans can

be straightened as follows:

CAUTION

To avoid personal injury, before servicing

header/mower conditioner or opening drive

covers, follow procedures in Section 7.1

PREPARATION FOR SERVICING, and

Section 7.2 RECOMMENDED SAFETY

PROCEDURES.

a. Heat the deformed area with a heat gun until the

poly is almost sticky.

b. Push out the dent, and then apply a cold wet

rag. Keep wetting the rag in cold water, and

applying it on the area until cool. This ensures

the poly retains its shape.

NOTE

If the dent is too severe, and has

stretched the poly, it may be necessary

to locally remove the poly. Use a plastic

welder to rejoin the material.

Replacement pans are also available

from your Dealer.

7.11.4 Rubber Fingers

Rubber fingers should be replaced if missing

or damaged.

a. Remove nut and bolt (A), and remove finger (B).

b. Position new finger in holder, and install bolt and

nut. Rubber finger should be free to move after

bolt is tightened.

7.11.5 Stripper Bars

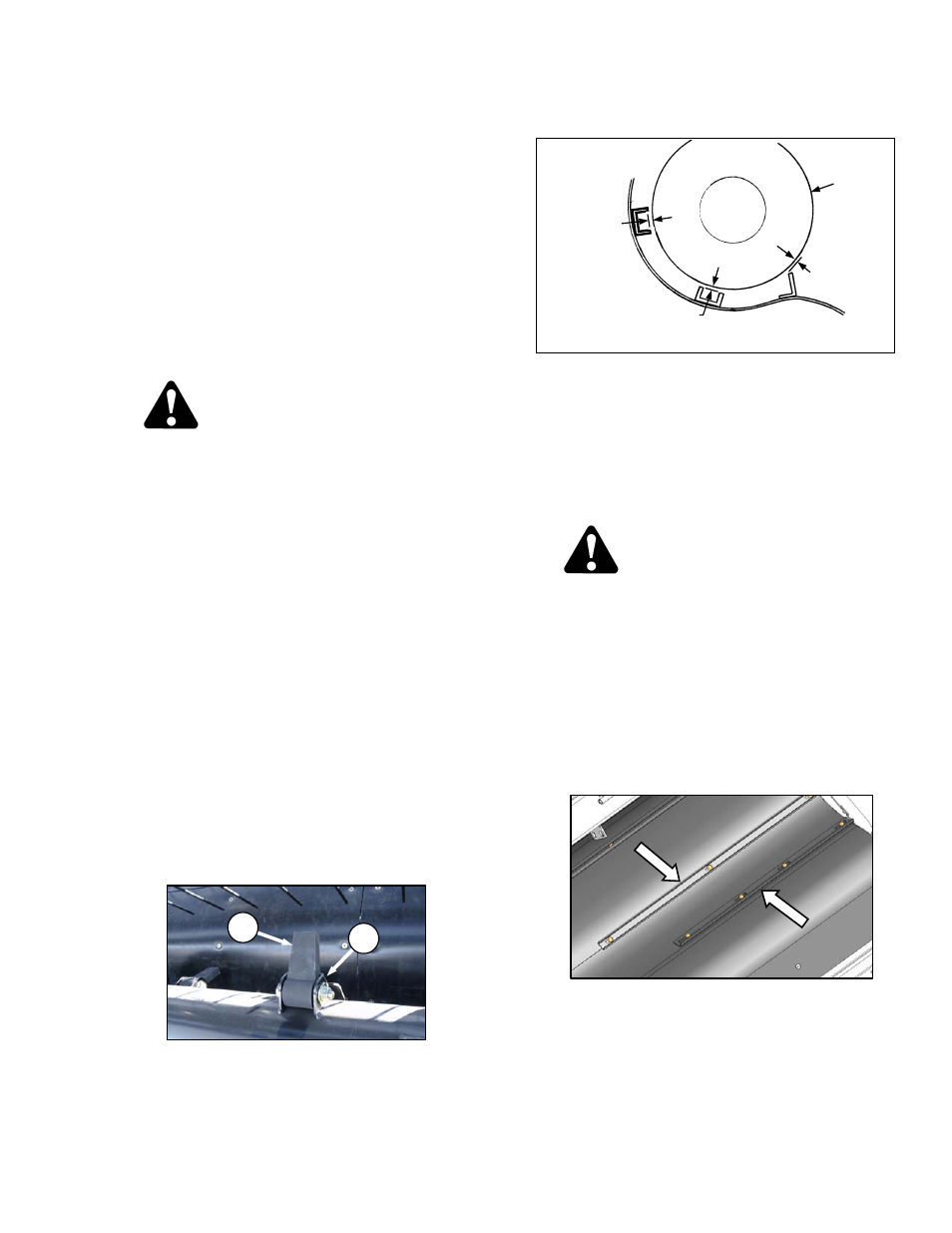

To maintain proper clearance between auger

and stripper bars, bars may need replacing due

to wear or damage. Shims may also need to be

installed to compensate for local irregularities in

the structure.

If after adjusting stripper bars, auger position

needs to be adjusted, refer to Section 6.17.4

Auger Position.

WARNING

To avoid bodily injury or death from

unexpected start-up or fall of raised

machine, stop engine, remove key, and

engage lift cylinder stops before going

under machine.

7.11.5.1 Removing Stripper Bar

Heavy crops may cause plugging across the

auger due to restricted flow at the stripper bars.

Remove the lower stripper bar, and if necessary,

remove the center stripper bar as follows:

a. Remove bolts attaching stripper bar to pan.

b. Remove

stripper

bar.

c. Replace bolts in pan.

NOTE

Special countersunk bolts are available

from your Dealer.

1/32–5/32 in

(1–4 mm)

CLEARANCE

1/32–5/32 in

(1–4 mm)

CLEARANCE

1/32–5/32 in

(1–4 mm)

CLEARANCE

AUGER

B

A

AUGER NOT SHOWN FOR CLARITY