Caution – MacDon A40-D Pull-Type User Manual

Page 167

SECTION 7 MAINTENANCE AND SERVICING

169000

165

Revision F

7.18 MAINTENANCE

SCHEDULE

The following maintenance schedules list

periodic maintenance procedures, and are

organized by service intervals. Regular

maintenance is the best insurance against early

wear and untimely breakdowns. Following this

schedule will increase machine life. For detailed

instructions, refer to the specific headings in

Section 7 MAINTENANCE AND SERVICING.

Recommended service intervals are in hours of

operation. Where a service interval is given in

more than one time frame, e.g., 100 hours or

Annually, service the machine at whichever

interval is reached first.

IMPORTANT

Recommended intervals are for average

conditions. Service the machine more

often if operated under adverse conditions

(severe dust, extra heavy loads, etc.).

CAUTION

Carefully follow safety messages given

under Section 7.2 RECOMMENDED SAFETY

PROCEDURES.

7.18.1 Self-Propelled Mower Conditioner

NOTE

The following service schedule is only applicable to the Auger Header.

Refer to your windrower operator’s manual for windrower maintenance.

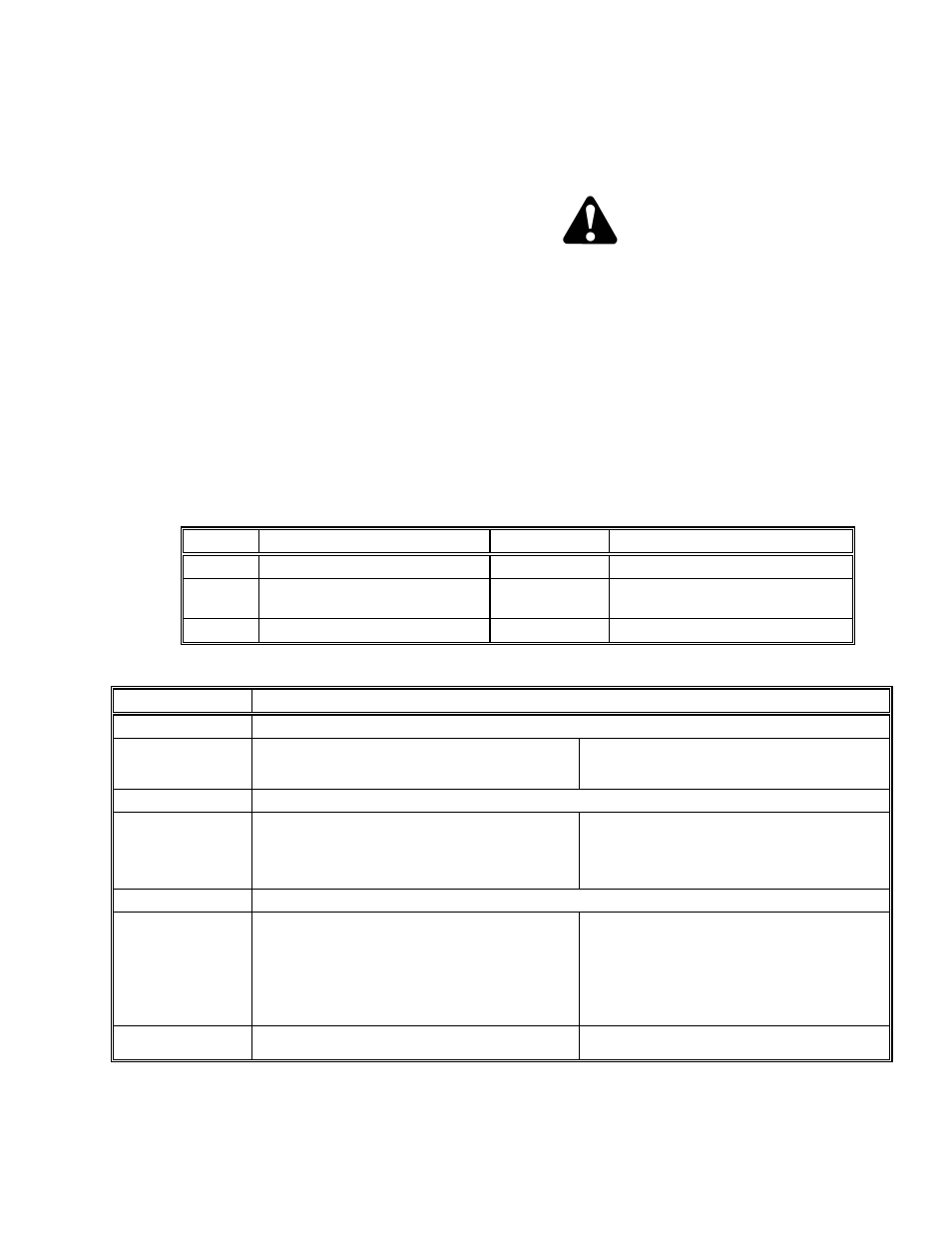

7.18.1.1 Break-In Inspection: Self-Propelled

HOURS ITEM

CHECK REFERENCE

5

Hardware Torque Section

7.3.1

5, 25,

and 50

Knife Drive Belt

Tension

Sections 7.8.10, and 7.8.11

10

Knife Drive Box Mounting Bolts

Torque

200 ft·lbf (270 N·m) Section 7.8.12

7.18.1.2 Interval Maintenance: Self-Propelled

INTERVAL SERVICE

FIRST USE

Refer To Section 7.18.1.1 Break-In Inspection: Self-Propelled

100 HOURS OR

ANNUALLY *

1. Check Conditioner Drive Gearbox

Lubricant Level.

2. Check Knife Drive Box Lubricant Level.

3. Check Knife Drive Box Mounting

Bolt Torques.

END OF SEASON

Refer To Section 6.19 STORAGE.

10 HOURS OR

DAILY

1. Check Hydraulic Hoses And Lines For Leaks.

2. Oil Knife (Except In Sandy Conditions).

3. Check Knife Sections, Guards, and

Hold-Downs.

4. Oil Reel Drive Chain (except A40-D).

5. Oil Auger Drive Chain (except A40-D).

6. Check Knife Drive Box Bolt Torque (First

10 Hours Only; Every 100 Hours After).

25 HOURS

1. Grease

Knife

Head.

50 HOURS

1. Grease Reel Shaft Bearings.

2. Grease Auger Shaft Bearings.

3. Grease Auger Jack-Shaft Bearings

(except A40-D).

4. Grease Conditioner Universal Shafts.

5. Grease Conditioner Shaft Bearings.

6. Grease Roll Pivots Bearing.

7. Grease Tine Tube Bearings (A40-D).

8. Grease Gauge Roller Bearings.

9. Change Knife Drive Box Lubricant (First 50

Hours Only; Every 1000 Hours After).

10. Change Conditioner Drive Gearbox

Lubricant (First 50 Hours Only; Every 1000

Hours After).

1000 HOURS OR

3 YEARS

1. Change Knife Drive Box Lubricant.

2. Change Conditioner Drive Gearbox

Lubricant.