Unloading & assembly – MacDon 963 Harvest Header User Manual

Page 67

66

UNLOADING & ASSEMBLY

INSTALL GAUGE WHEEL / TRANSPORT OPTION

(continued)

7. Attach the three gauge wheels to hubs. Torque

wheel bolts to 80 to 90 ft.lbs. (110 to 120 N

⋅

m).

8. Install pins (B) in stand position as shown.

(Both supports.)

9. Left wheel caster is shipped in field position,

with wheel outboard of support.

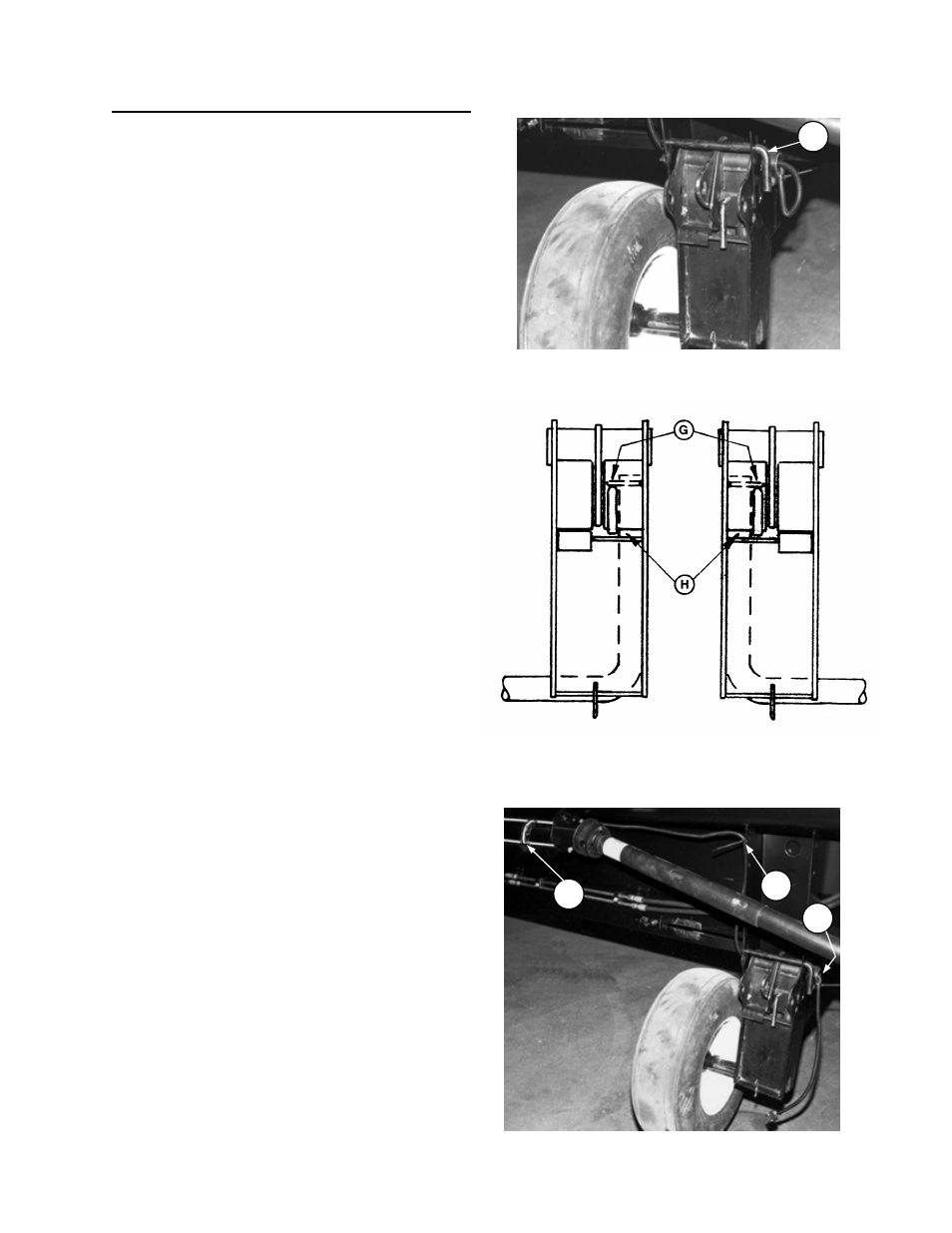

NOTE: Left wheel caster can be installed at left or

right side of wheel support. This positions the left

wheel inboard or outboard of wheel support as

desired. If caster is being moved to opposite side,

note that U-shaped loop (G) on caster must point

to middle of wheel support. Access to loop (G) is

through slot (H).

10. Lower header onto gauge wheels and 6" (150

mm) blocks under cutterbar. Remove shipping

stands.

11. Check tire pressure. Inflate to 42 to 46 psi (290

to 315 kPa).

12. Assemble light package to header as follows:

a. Open left hand drive shield and route header

section of wiring harness through inside of

frame tube to right endsheet.

NOTE: The end of the harness with the 6-way

connector goes to the right endsheet.

b. Route the other end of this harness (with 4-way

connector) through slot in left endsheet (see [J]

top photo, next page), along driveline shield to

left gauge wheel leg, down and through tube

which secures wheel support to header leg.

Leaving 22 in. (560 mm) of harness protruding

from inboard end of tube (A), use the large

plastic ties (E) to secure the harness to

driveline shield. For 30 ft. headers, also use

one small plastic tie (F) to secure harness at

flange on header leg.

LEFT WHEEL CASTER:

ALTERNATE POSITIONS

LEG PINS IN STAND POSITION

B

HARNESS ROUTING - LEFT WHEEL SUPPORT

A

F

E