Unloading & assembly – MacDon 963 Harvest Header User Manual

Page 65

64

UNLOADING & ASSEMBLY

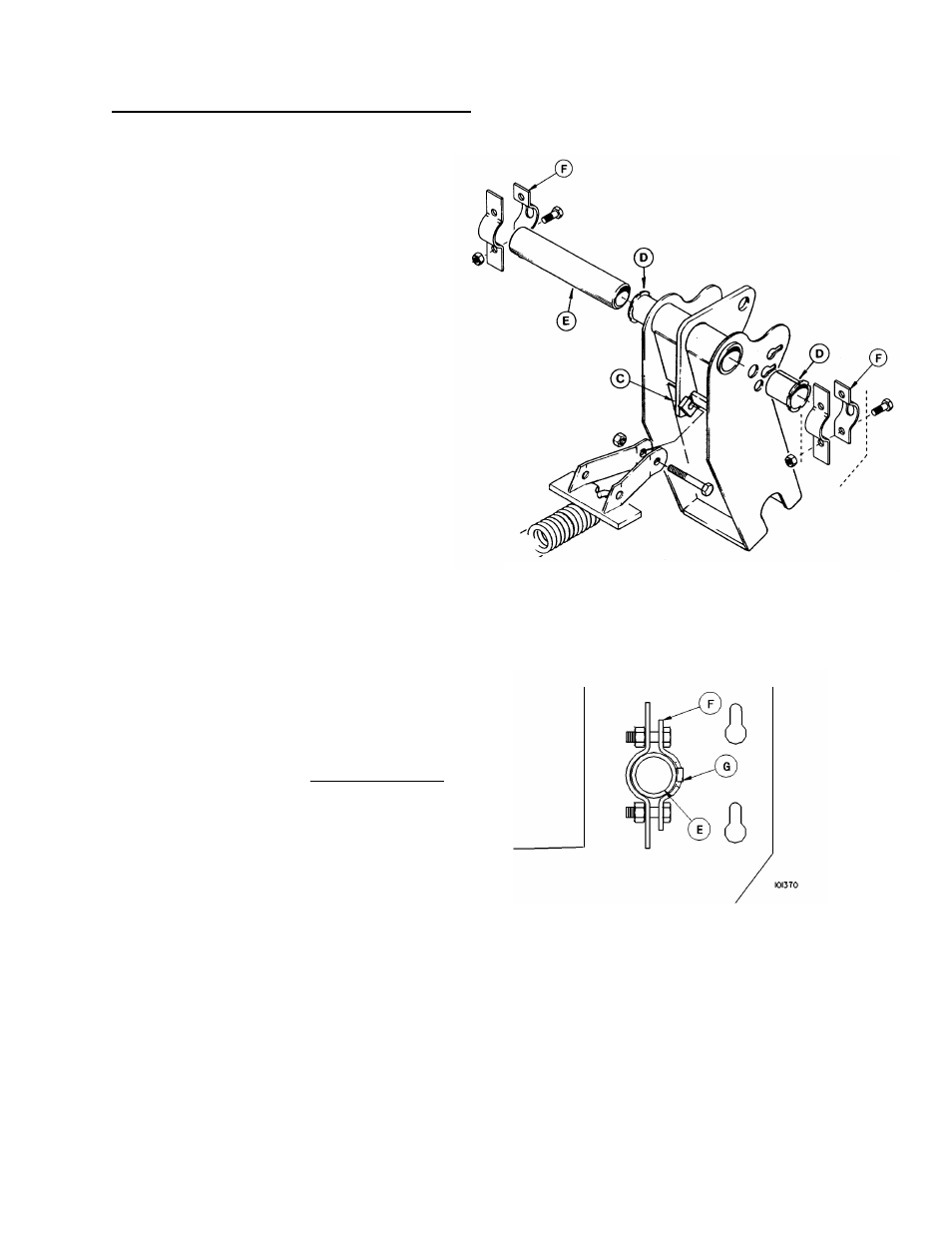

INSTALL GAUGE WHEEL / TRANSPORT OPTION

NOTE: These instructions apply to the gauge

wheels with transport option. For instructions for

installing the standard gauge wheel package, see

previous page.

1. Remove chain hooks and move lifting vehicle

to rear of header. Attach chain to center link

anchor on frame tube and raise rear of header.

NOTE: Remove header stands from header outer

legs. These stands are not used with gauge

wheels.

2. Identify right and left wheel supports: Left

wheel support has single wheel caster, right

wheel support is attached to dual wheel beam.

3. Front end of gauge wheel spring assembly

was attached to header outer legs before

header was lowered (see page 62). Attach

clevis at other end of spring to plate (C) at left

and right wheel supports, using 5/8 hex head

bolt and lock nut.

NOTE: Do not collapse clevis by over-tightening

hardware. Clevis must be free to rotate.

NOTE: For ease of installing right wheel support,

remove 1/2 inch bolt (H, next page) securing pivot

shaft, allowing removal of dual wheel beam.

4. Ensure plastic bushings (D) are installed (2 per

support). Position wheel support assembly in

header leg and install tube (E) from outside

header leg through wheel support. Attach two

brackets (F) with 1/2 x 1 ¼ inch bolts and nuts

to the brackets welded to header leg.

IMPORTANT: Tighten to 80 ft. lbs. (110 N

⋅

m).

Be sure that welded tab (G) on tube (E) is

engaged in slot in bracket (F) on one side.

Repeat at other gauge wheel support.

ENGAGE TAB IN BRACKET SLOT

INSTALL WHEEL SUPPORTS (L/H SHOWN)