Header operation operating variables (continued) – MacDon 963 Harvest Header User Manual

Page 19

18

HEADER

OPERATION

Operating Variables (continued)

CUTTING HEIGHT

Cutting height will vary, depending on whether

windrowing or straight-cutting, type of crop, etc.

See "Windrowing" for stubble height recommen-

dations.

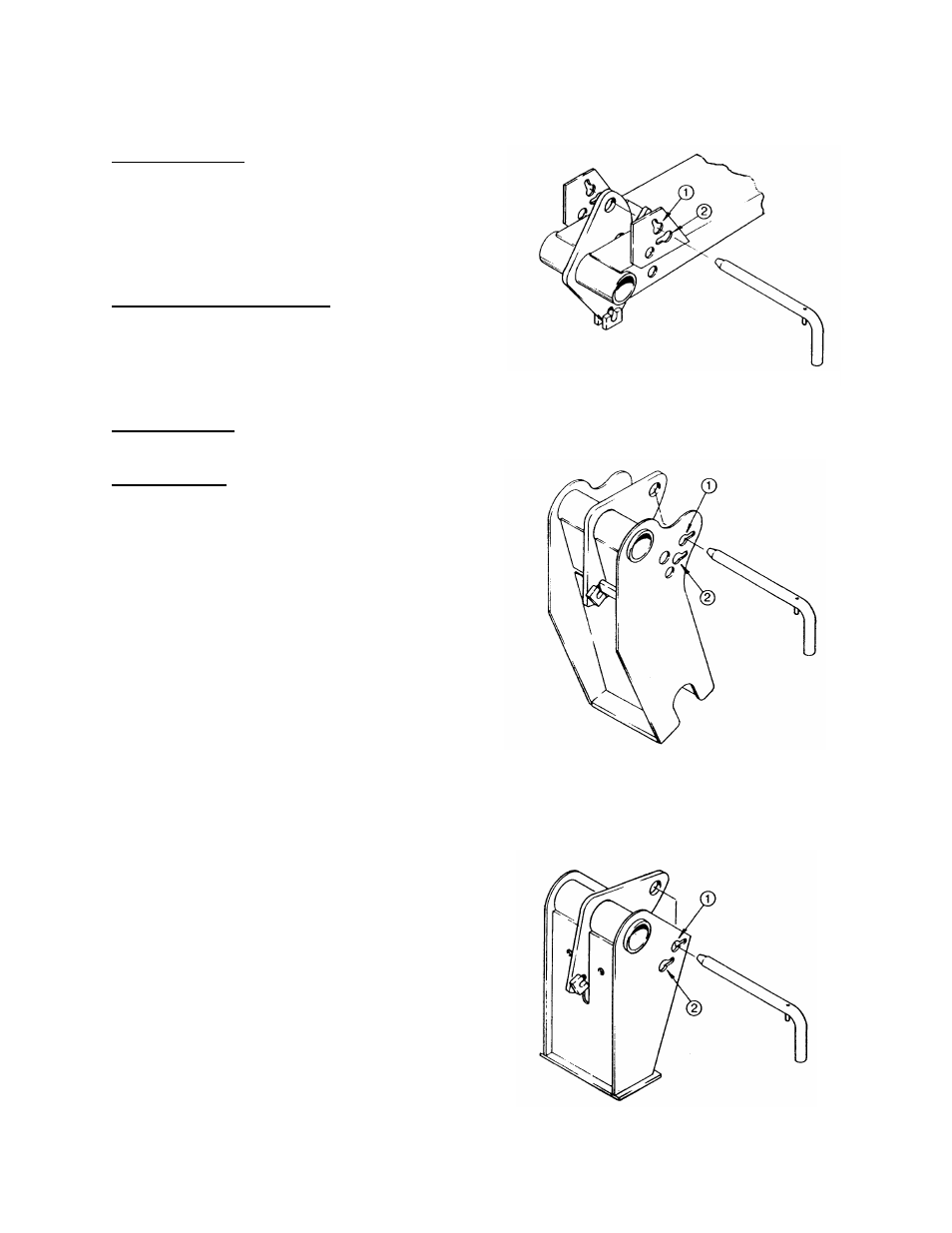

Gauge Wheel Field Positions:

For headers equipped with gauge wheels or the

gauge wheel/transport package, choose Field

Position 1 or 2 to maintain proper gauge wheel

spring force at desired cutting height.

Field Position 1 when cutterbar is above the

ground (4 to 12 in. [100 to 300 mm] cutting height.

Field Position 2 when cutterbar is on the ground

(0 to 4 in. [100 mm] cutting height).

NOTE: When changing gauge wheel field position,

readjust header flotation. See "Header Flotation" in

Windrower Tractor or Combine Adapter Operator's

Manual.

NOTE: Gauge wheel field position should also be

related to Header Angle. Use Position 2 for flatter

header angles and Position 1 for steeper header

angles.

STANDARD GAUGE WHEEL SUPPORT

TRANSPORT PACKAGE -

LEFT WHEEL SUPPORT

TRANSPORT PACKAGE -

RIGHT WHEEL BEAM SUPPORT