Maintenance/service – MacDon 963 Harvest Header User Manual

Page 48

47

MAINTENANCE/SERVICE

Wobble Box Assembly/Disassembly

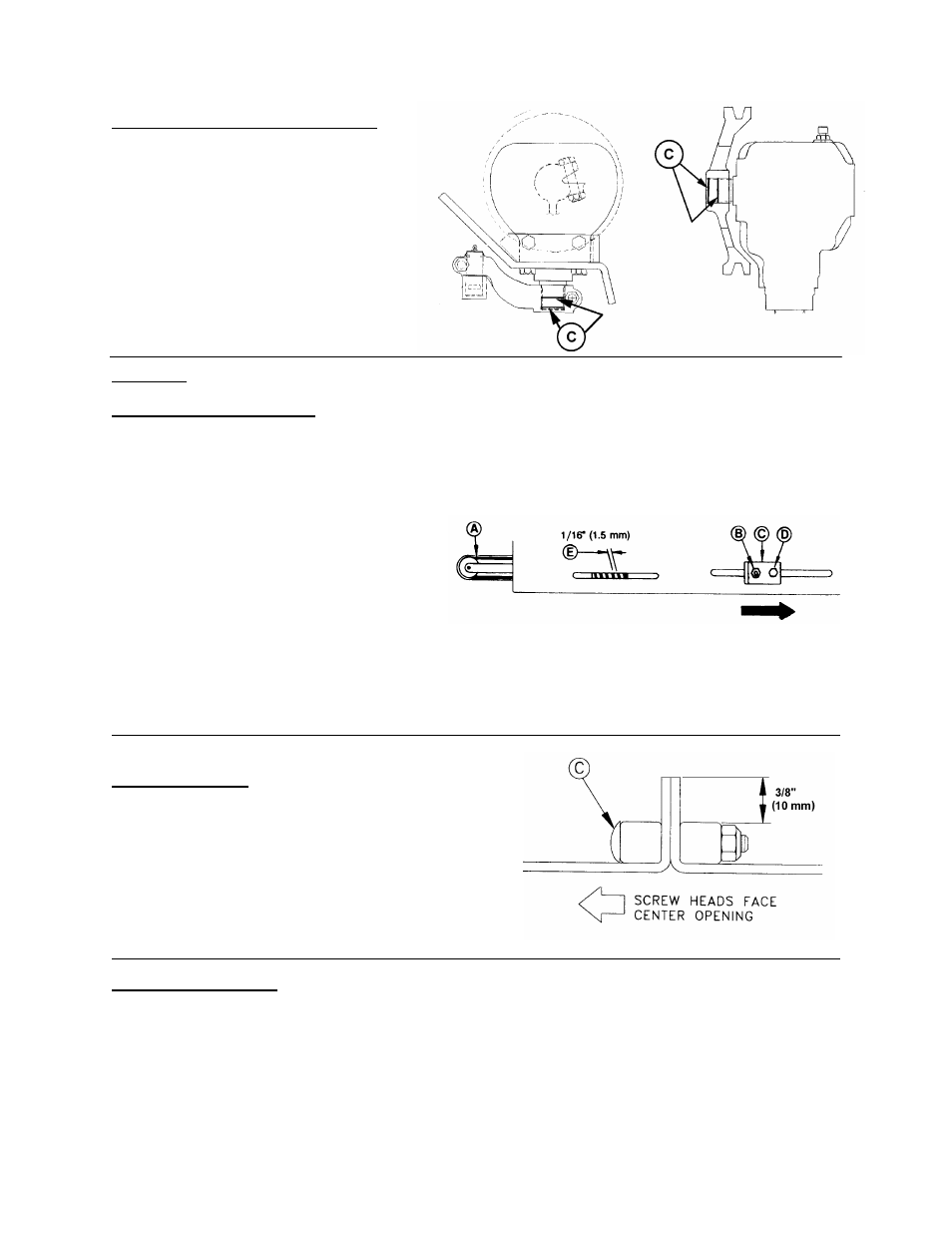

When reinstalling drive arm or pulley:

1. Remove any rust or paint from inner

spline. For replacement parts, remove

oil/grease with degreasing agent.

2. Before assembly, apply Loctite® #243

adhesive (or equivalent) to spline. Apply

in two bands (C) as shown, with one

band at end of spline and one band

approximately mid-way.

DRAPERS

Draper Tension Adjustment

Draper tension should be just enough to prevent slipping.

Spring assemblies at each outboard roller control draper tension. Set draper tension as follows:

1. Check that draper guide (A) is properly

engaged in grooves of both drive and idler

rollers.

2. Loosen locknut (B) and slide bracket (C)

away from outboard roller as far as hand

force allows.

NOTE: It may be necessary to tap bracket

(C) with a hammer to start it moving.

3. Tighten locknut (B) to secure the new position.

4. Turn bolt head (D) clockwise until gap (E) between idler spring coils is 1/16 inch (1.5 mm).

IMPORTANT: Do not over-tighten draper so that spring is completely collapsed (no gap between coils).

Operating with spring collapsed may lead to failure of draper, draper rollers and/or tightener components.

Replacing Drapers

When installing drapers:

1. Ensure you have the proper length draper.

2. Adjust draper opening. See page 21.

3. Install screws (C) with heads facing center opening.

Moving Draper Motors

Draper drive motors may be moved from outboard to inboard and vice versa. The inboard configuration

provides more conveying torque in heavy crops and is for windrowing applications only. The maximum delivery

opening is recommended with motors inboard.

In combine applications motors must be in outboard configuration because of interference with adapter

conveyors.

For instructions on moving draper motors, see "Assembly" section, page 75.