Header operation operating variables – MacDon 963 Harvest Header User Manual

Page 23

22

HEADER OPERATION

Operating Variables

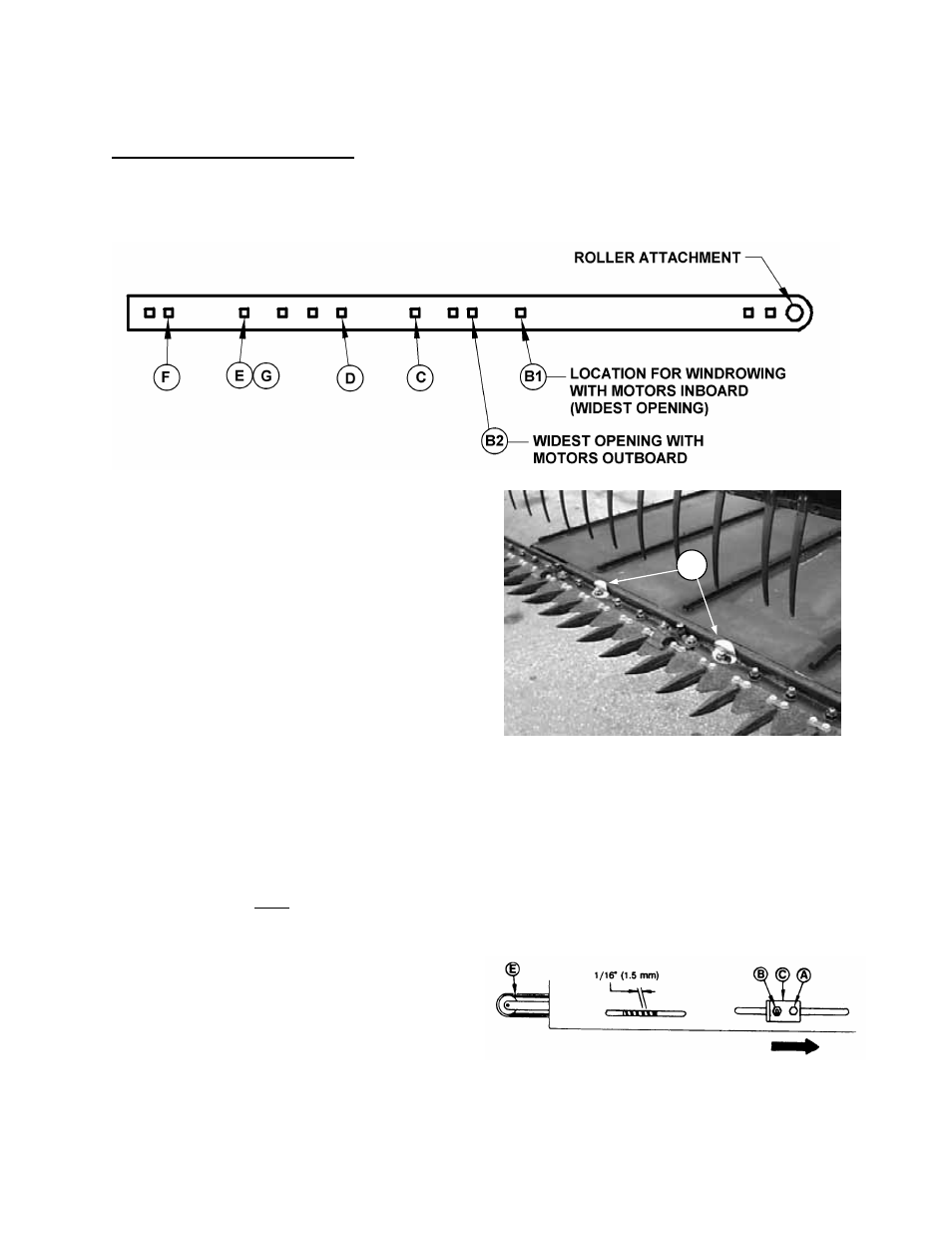

To adjust delivery opening width

3. continued)

Bolt opening adjustment bars to deck at the hole corresponding to the draper row. For example if drapers

are to be connected at row E (from chart on previous page), move roller until hole (E) aligns with deck

mounting slot. Use a carpenter’s square to ensure roller is square to deck and tighten hardware.

NOTE: For access to bolt securing the

adjustment bar at cutterbar on L/H (moveable)

deck, remove retainer clips (G) and, if installed,

the front edge draper seals and clips (see page

48). Raise front of deck for access to bolt.

4. Cut excessive flap off of draper, leaving 3/8"

(10 mm) extending above the connector. Trim

the new ends at the front corners as shown on

page 21. This allows draper to fit properly

under front draper seal to prevent tearing of

front edge. Use the cut-offs as a guide for

trimming. Keep the cut-offs for use as a splice.

5. NOTE: Place connector tube so holes closest

to end of tube are at the cutterbar.

Connect draper with screw heads facing center

opening.

NOTE: To reduce the opening size after it has

been enlarged, a short section of draper

(available from your dealer) can be added to

increase draper length.

6. Slide bracket (C) away from outboard roller as

far as hand force allows. Check that draper V-

guide (E) is properly engaged in grooves at

rear of both rollers.

7. Tighten nut (B) to secure the position of

bracket (C).

8. Apply draper tension by turning bolt (A) clock-

wise until gap between idler spring coils is 1/16

inch (1.5 mm).

IMPORTANT: Do not collapse spring. The

spring maintains draper tension and prevents

over-tension. If spring is collapsed, damage to

draper and rollers may result from excessive

draper tension.

APPLY DRAPER TENSION

REMOVE CLIPS ON LEFT DECK

FOR BOLT ACCESS

G