Header operation operating variables – MacDon 963 Harvest Header User Manual

Page 18

17

HEADER OPERATION

Operating Variables

Satisfactory function of the header requires

making the proper adjustments to suit various

crops and conditions.

Correct operation reduces crop loss and allows

cutting of more acres. As well, proper adjustments

and timely maintenance will increase the length of

service you receive from the machine.

The variables listed at right will affect the

performance of the header. You will quickly

become adept at adjusting the machine to give you

the desired results.

GROUND SPEED

•

Ground speed should be such that the sickle can cut crop smoothly and cleanly, while giving the desired

delivery of material to the opening. Excessive ground speed results in "ragged" cutting. See "Windrowing"

for affects of ground speed on windrow formation.

•

In tough-to-cut crops like flax, reduce ground speed to reduce loads on cutting components and drives.

•

Higher ground speeds require heavier float settings to prevent excessive bouncing. This will result in

increased cutting component damage.

•

As ground speed is increased, draper and reel speed should be increased to handle the extra material.

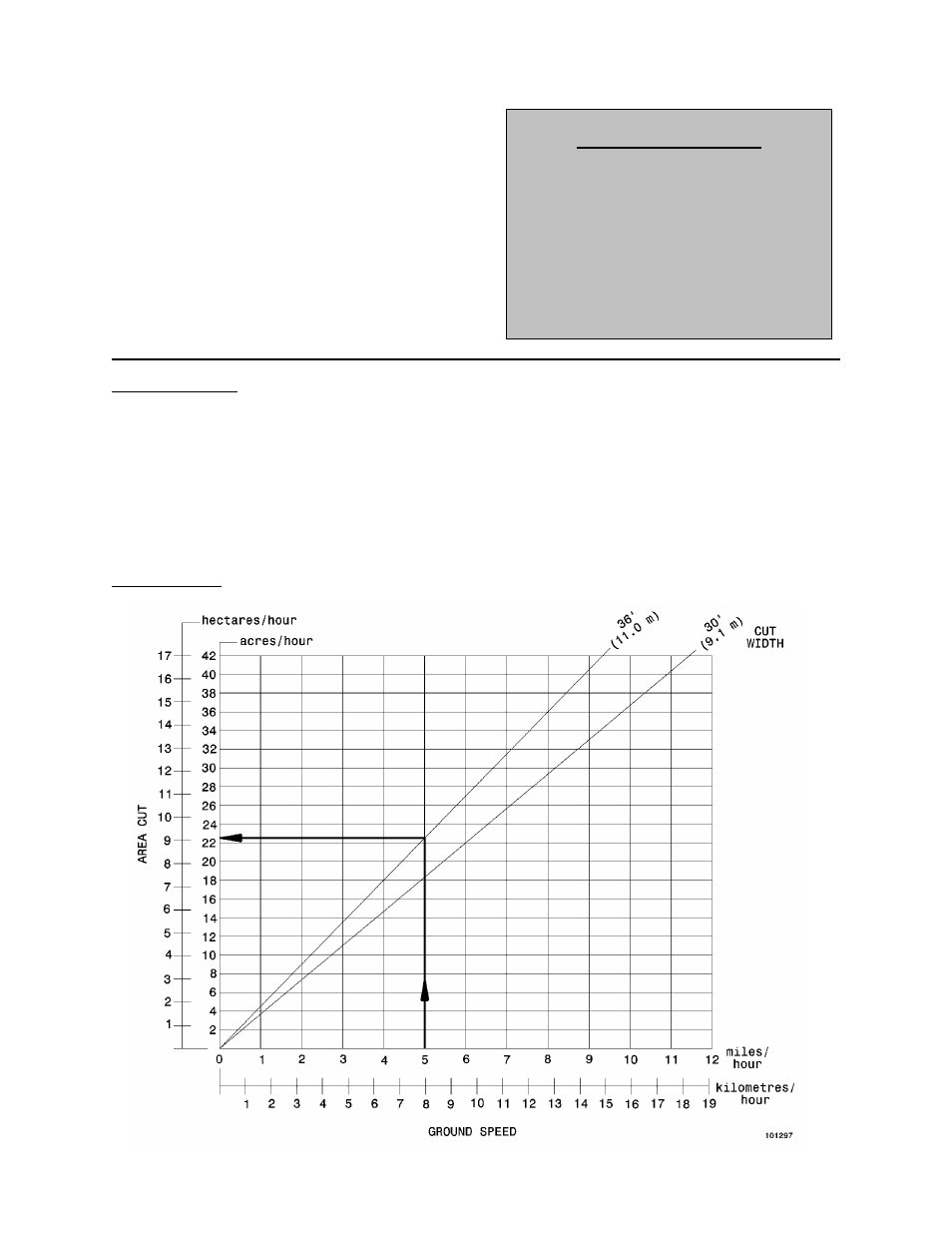

The chart below indicates the relationship between ground speed and area cut for the two header sizes.

Example shown: At a ground speed of 5 miles per hour (8 km/h) with a 36 ft. header, the area cut would be

approximately 22 acres (9 hectares) per hour.

OPERATING VARIABLES

1. Ground Speed

2. Cutting Height

3. Header Flotation

4. Header Angle

5. Draper Speed

6. Delivery Opening Width

7. Reel Speed

8. Reel Height

9. Reel Fore-Aft Position

10. Divider Angle