Preload the spiral washers – MTS Series 647 Hydraulic Wedge Grips User Manual

Page 72

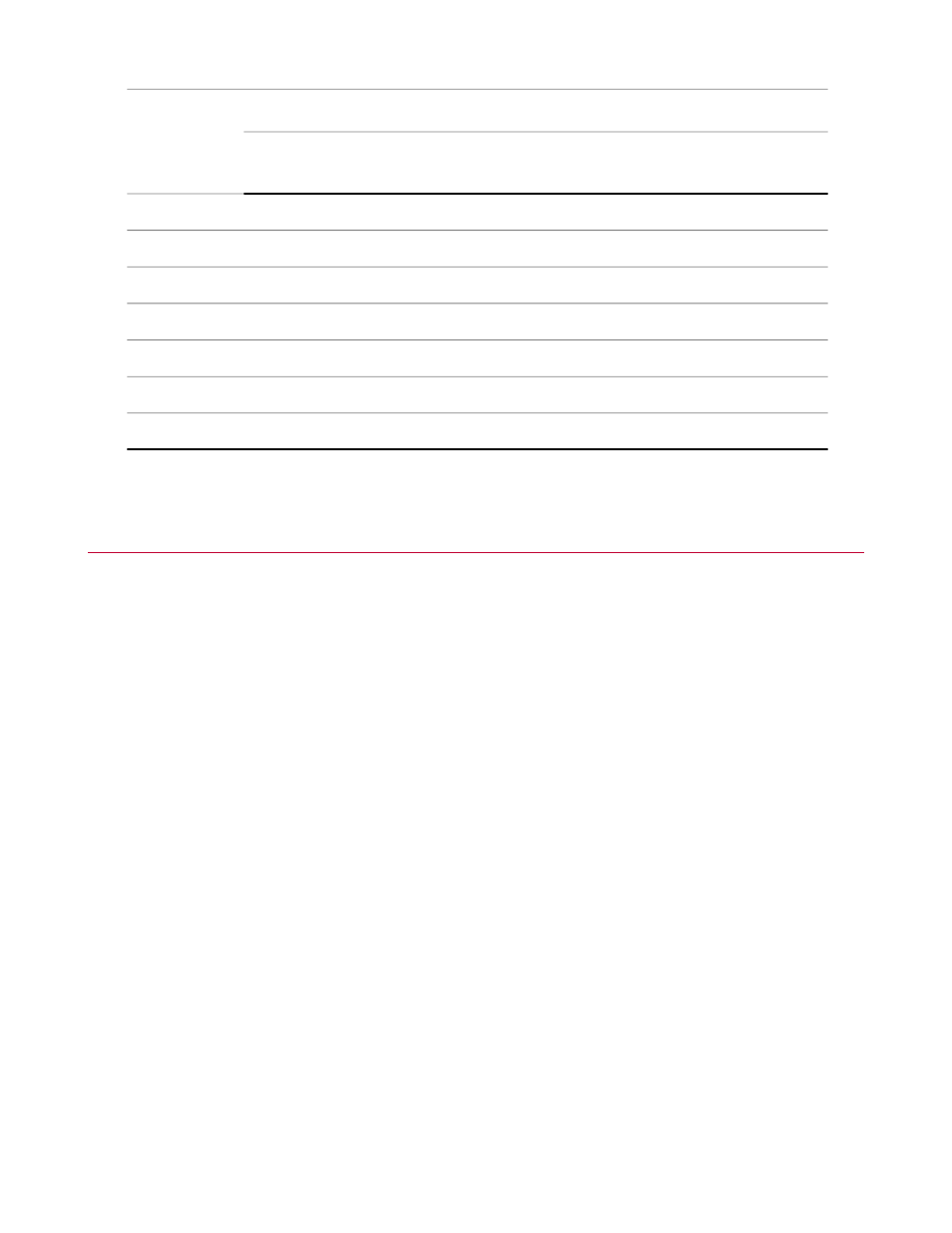

Grip Rotations and Shim Part Number

Kit Part

Number

1 Turn (360°)

1/2 Turn (180°)

1/4 Turn (90°)

1/8 Turn (45°)

1/16 Turn

(22.5°)

443665-21

443665-19

443665-20

443665-07

443665-21

521050-04

443665-25

443665-22

443665-24

443665-24

443665-25

521050-05

443665-25

443665-23

443665-23

443665-24

443665-25

521050-06

443665-27

443665-26

443665-26

443665-02

443665-02

521050-07

443665-27

443665-26

443665-26

443665-27

443665-27

521050-08

443665-29

443665-28

443665-28

443665-15

443665-29

521050-09

443665-29

443665-28

443665-28

443665-15

443665-29

521050-10

Preload the Spiral Washers

The connector studs must be preloaded to prevent backlash. Preloading the connector studs requires that a

full tensile load be applied to a specimen mounted in the grips. Therefore, it is assumed that the system

hydraulics and the hydraulic grip supply are operational.

Required equipment:

•

The procedure requires that the spiral washers be installed on each connector stud in the force train. You

will also need two spanner wrenches.

•

Sometimes you might have multiple fixtures in the force train that have different force ratings. When

installing the fixtures pretensioned with spiral washers, install the fixtures with the lowest force rating first.

Then install any other fixtures from the lowest to the highest force rating.

1. Select force control at the system controller.

2. Turn on the system hydraulic pressure.

3. Select a dummy specimen that will withstand a tensile force 10 to 20% greater than the maximum force

to be applied during the test.

4. Adjust the output pressure of the hydraulic grip supply to the level determined in “Determine the Gripping

Pressure.”

5. Install the dummy specimen in the grips according to the steps provided in “Install a Specimen.”

72 Series 647 Hydraulic Wedge Grips Reference Manual

Installation