Warning – MK Diamond MKDX Profile Milling Machine User Manual

Page 25

25

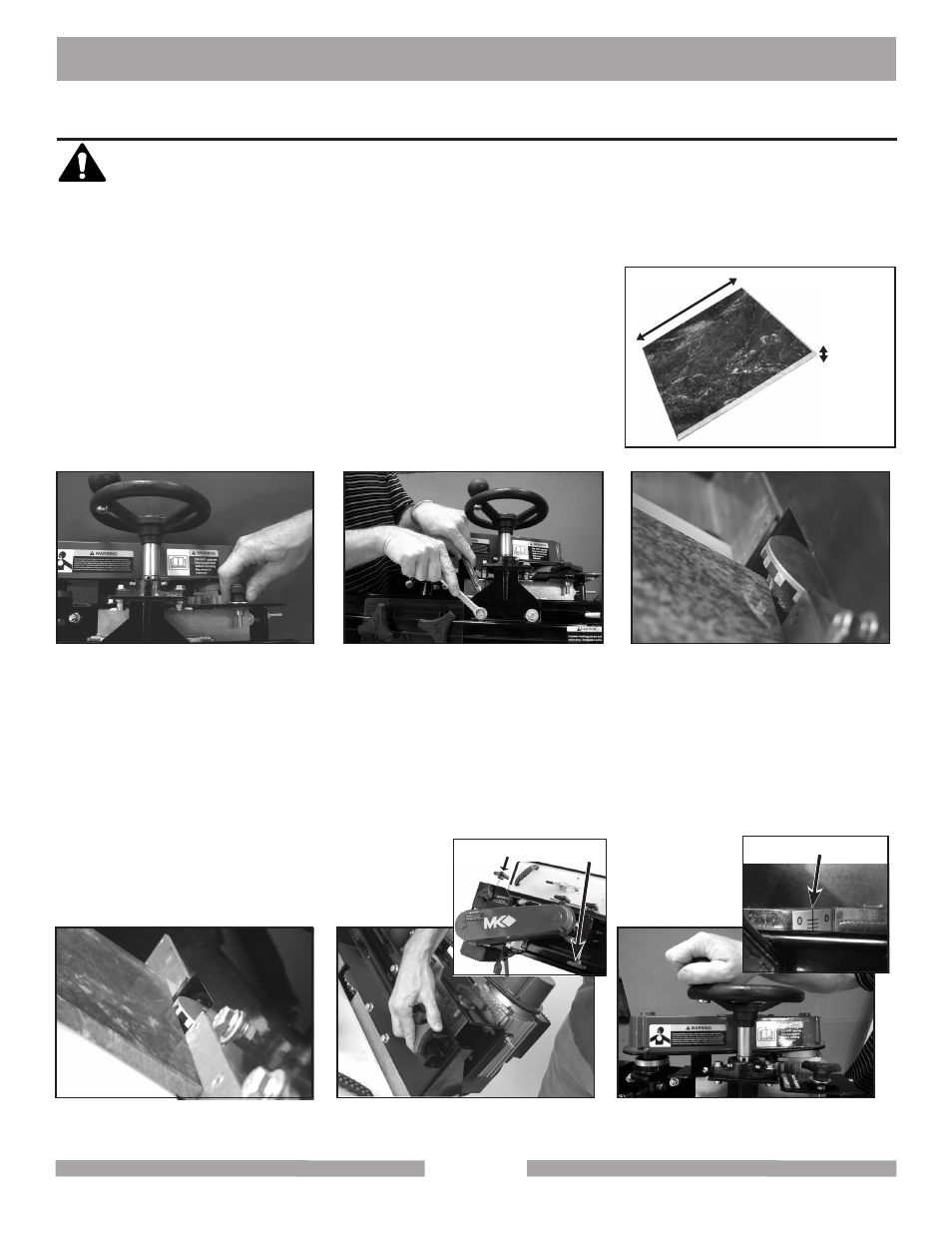

4. Profile wheel should be touching material. Only a gentle pressure should be needed when

pushing material slide through for shaping. DO NOT force the piece through or readjusting may

be needed (Figure 35).

5. Adjust horizontal bolts to material thickness (Figure 36). Be sure to tighten horizontal lock bolt

when done. Second horizontal bolt is located on opposite end of motor frame.

6. Turn material fine adjustment wheel for vertical adjustment to material width (Figure 37).

7. Replace spray guard.

MKDX

OPERATION

PROFILE WHEEL ADJUSTMENT

WARNING

Before performing any operation, make sure that the machine is unplugged.

Profile Wheel Adjustment

1. Remove spray guard. Unlock horizontal lock bolt (Figure 32).

2. For major vertical adjustments, loosen/tighten course vertical

adjustment bolts (Figure 33). These have been preset at the

factory for normal operation.

3. Sight down the material slide to gauge the wheel location to

material (Figure 34).

Fig. 32 Unlock lock bolt

The profile wheel adjustment is a two step process. There is the vertical adjustment for the width of

the material and the horizontal adjustment for the thickness.

Width of Tile

(Vertical)

Thickness of Tile

(Horizontal)

Fig. 33 Major vertical

(Pre-set for normal operation adjustments)

Fig. 34 Gauge wheel location

Fig. 35 Wheel touching material

Fig. 36 Adjust both horizontal bolts Fig. 37 Turn adjustment wheel using

the height scale guide

HORIZONTAL BOLTS

HEIGHT SCALE GUIDE