MK Diamond MKDX Profile Milling Machine User Manual

Page 23

23

MKDX

OPERATION

CLAMPING THE MATERIAL

DANGER

Before performing any operation, make sure that the machine is unplugged.

NOTICE

If the material is correctly positioned against the stainless steel wear bars and firmly clamped in

place, shaping will be accomplished perfectly.

WARNING

Before performing your shaping, make sure the profile wheel is sharp, correctly positioned and firmly se-

cured in place.

Adjusting the clamps is a two step process. First the clamps must be moved to the appropriate hole

locations and then the clamps height needs to be adjusted based on the thickness of material.

ADJUSTING FOR SIZE

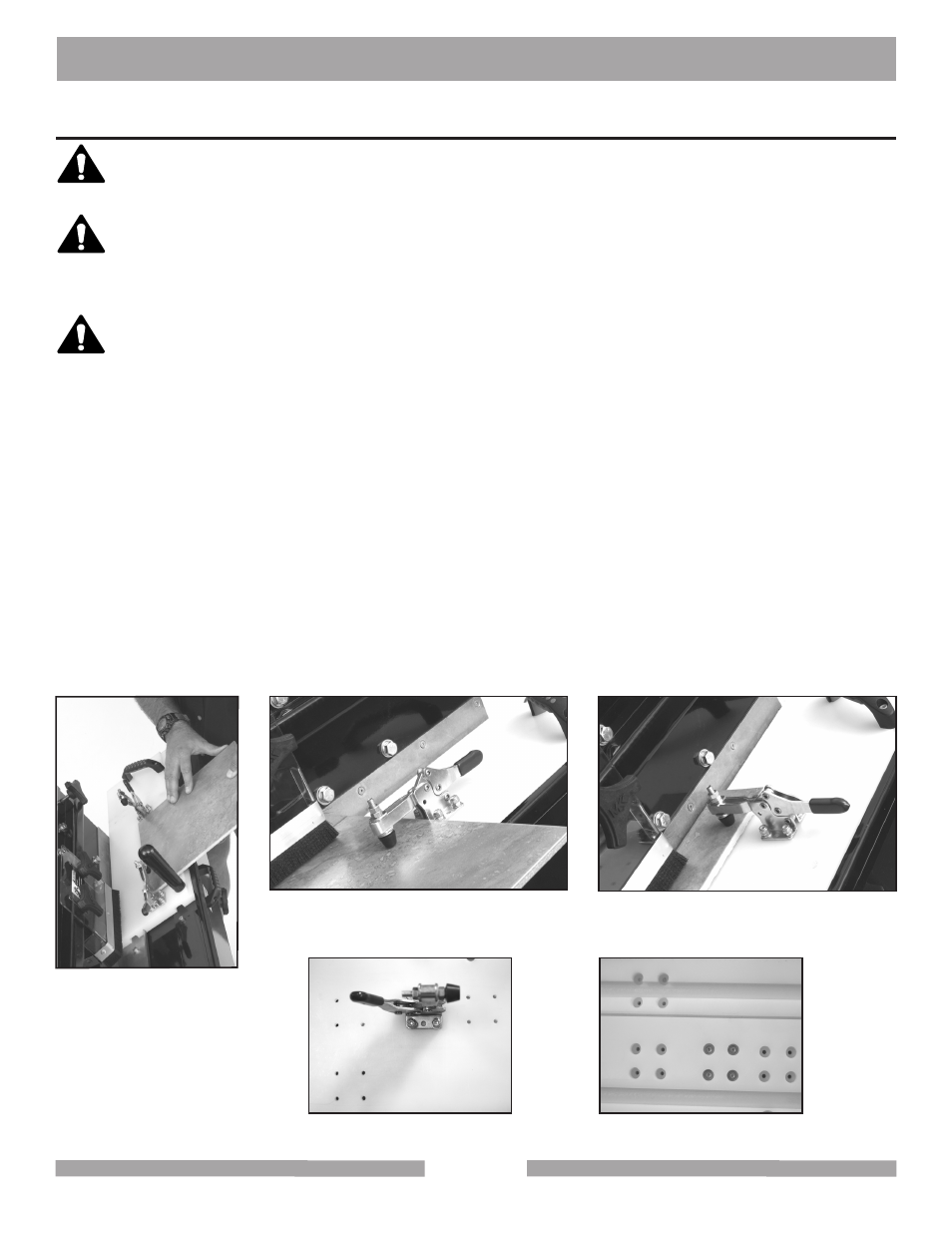

1. Place the material on the material slide (Figure 25).

2. Determine correct hole locations for clamps based on the size of the material (Figure 26).

3. Clamps may be rotated 90º for smaller strips. Move clamps to proper locations in order to secure

material (Figure 27).

4. Clamps may be moved further apart for larger materials (Figure 28).

5. Use wrenches to remove bolts and nuts to move clamps to desired positions. (View) Bottom of

the material slide (Figure 29).

6. Vertical handle may be moved for different sized pieces.

Fig. 25 Material Slide

Fig. 26 Determine hole locations

Fig. 27 Determine clamp position

Fig. 28 Top view

Fig. 29 Bottom view