Let's Go Aero LittleGiant Trailer LGT 1107 - T (Torsion based model) User Manual

Page 7

– 7 –

l

iTTle

G

ianT

T

railer

™

LGT1107rev0614

1

2

3

4

5

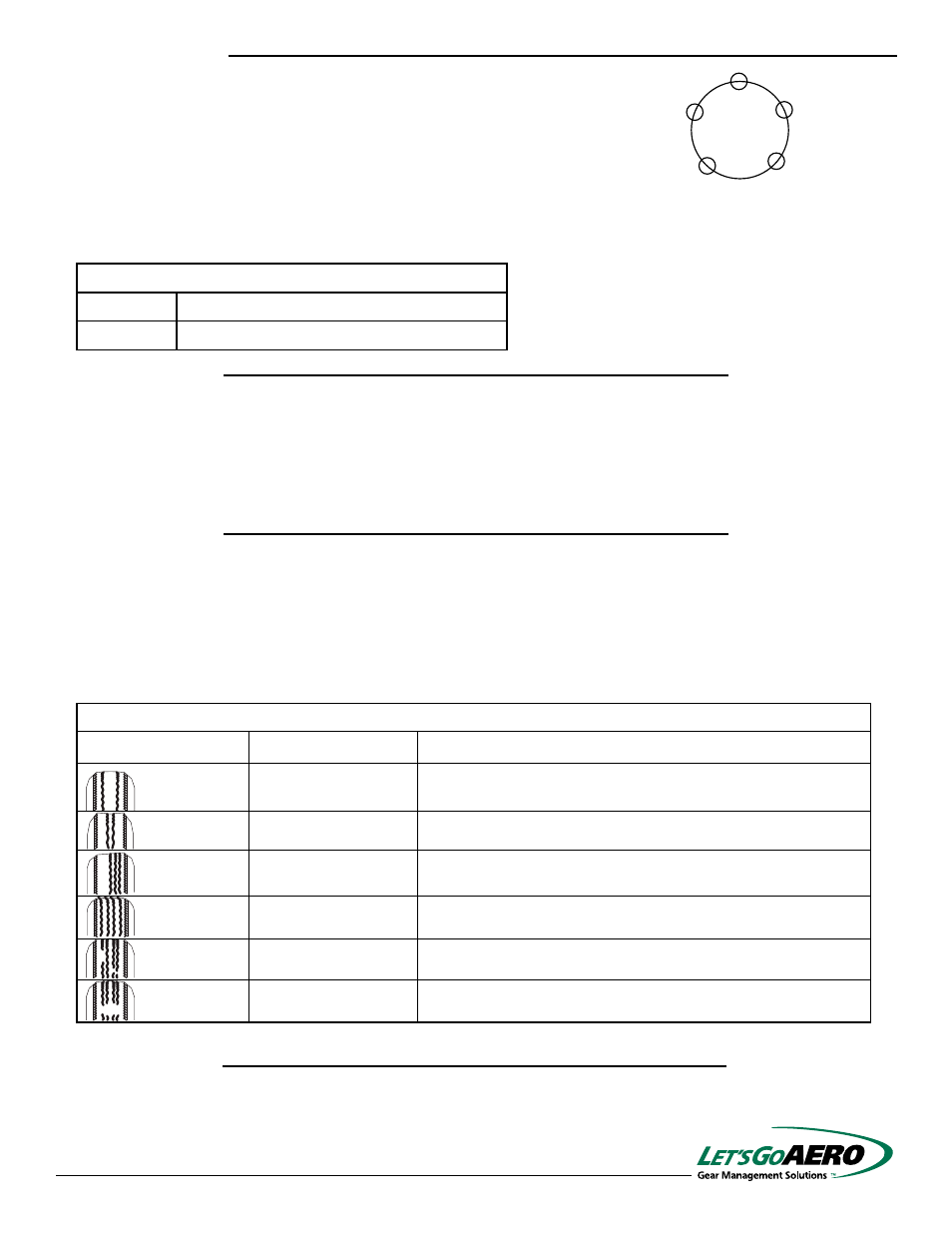

5 Bolt Pattern

W

heel

T

Orque

v

alueS

Wheel Size

1st Stage

2nd Stage

2nd Stage

13"

20-25 ft./lbs. 35-40 ft./lbs. *50-75 ft./lbs.

Tires

Like the tires on a car, the most important factor in the life of the tires on your trailer is their inflation pressure. The recom-

mended tire inflation pressure is 30 PSI. Underinflaton of tires will lead to added wear and tear and tire failure. During use

of your trailer, inflation pressure should be checked weekly and performed when the tires are cold (prior to operation of the

trailer). In doing this, you will ensure that you are achieving the maximum life and tread wear for your tires.

The proper procedure for the attachment of your wheels is listed at right.

1. Start all bolts or nuts by hand to prevent cross threading.

2. The tightening of the fasteners should be done in stages. Following the

recommended sequence above, tighten fasteners per the wheel torque

chart below.

3. Wheel fasteners should be torqued before the first initial road usage and

after each wheel removal. Check and retorque the wheel fasteners after the first 50 miles and again at 500 mile

intervals. Check periodically thereafter to ensure that the proper torque values are maintained.

Wheels and Tires – Inspection and Maintenance

Wheels should be visually checked periodically for dents or cracks. Whenever it is required to have a tire replaced on a

rim, the wheel needs to be checked for balance and distortion.

Tire wear should also be checked often for abnormal or excessive wear. The following chart will aid you in troubleshooting

if abnormal or excessive tire wear should occur. It is important to monitor tire wear, as once a wear pattern becomes firmly

established in a tire it is difficult to stop, even if the underlying cause is corrected.

T

ire

W

ear

d

iaGnOSTiC

C

harT

Wear Pattern

Cause

Action

Center Wear Overinflated tire

Adjust tire pressure to specific load rating per tire catalog

Edge Wear

Underinflated tire

Adjust tire pressure to specific load rating per tire catalog

Side Wear

Loss of camber

Make sure load does not exceed axle rating. Realign axle

or overloading

at axle shop

Toe Wear

Incorrect toe-in

Align at alignment shop

Cupping

Out-of-balance

Check bearing adjustment and balance tires

Flat Spots

Wheel lockup

Avoid sudden stops when possible and adjust brakes

and tire skidding