Cam designer basic – Lenze Cam Designer Basic User Manual

Page 23

L

2.1 EN - 09/2005

23

Cam Designer Basic

Operation

Create a new project

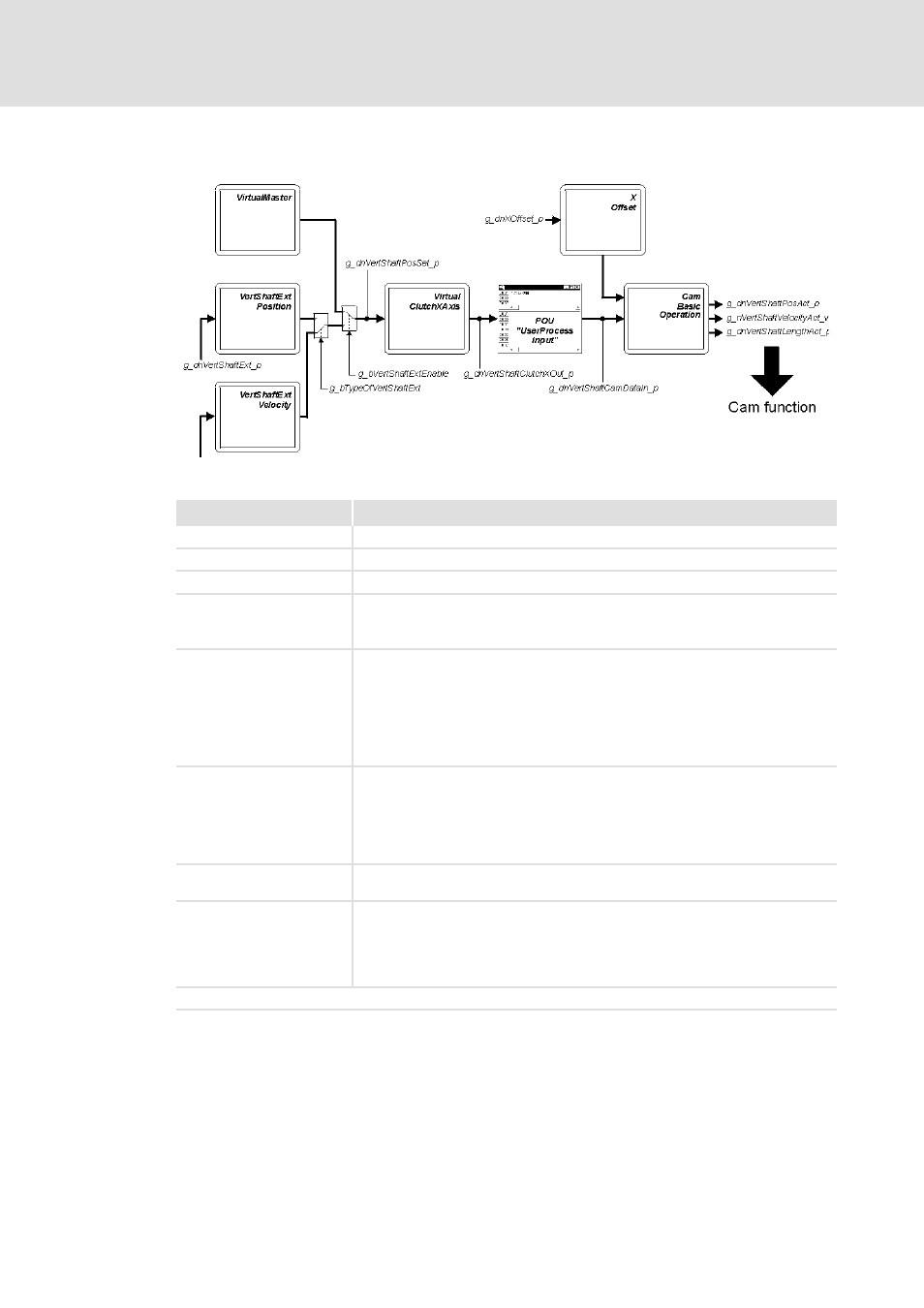

The following overview shows the relevant global data for the electrical shaft function. Sig-

nal flow between the template functions for the Electrical shaft.

Enter the indicated values into the dialog box Master ein.

Dialog object

Description

Input field Name

Name of the master axis

Input field Minimum

In the dialog box Master the 0.0000 must always be entered here.

Combination field Unit *

The unit used

Input field Maximum *

Cycle

• An electrical shaft can be divided e.g. from 0° to 360° or from 0 to 100mm.

• In this case, one master cycle amounts to 360° or 100mm

Input field Cycles/min

Production cycles in 1/min

The value can maximally amount to 199%.

• The machine speed which you want to reach with this profile can be set in the in-

put field Cycles/min.

• Serves the display

–to dimension the acceleration

–of the time cams of the cam group.

Input field

Rated cycles/min

Production cycles in 1/min

The nominal value can maximally amount to 199%.

• The maximum possible machine speed can be entered in the input field Rated

quantity cycle/min.

This entry is important for the acceleration precontrol.

(Servo PLC / servo cam 9300EK)

Input field

Gear factors z2/z1 *

Ratio of an upstream gearbox.

(e.g. 100/1 as real value)

Input field Feed constant *

Path per revolution at the output end of the gearbox

(if an angle is stated, one revolution = 360°)

The physical unit entered is converted to the encoders.

• Enter, for instance, the leadscrew pitch.

• When entering increments, enter the number of increments per revolution.

Fields must be filled with * !