Troubleshooting guide – Landoll 6230 Disc User Manual

Page 94

5-2

F-440-0113 Edition

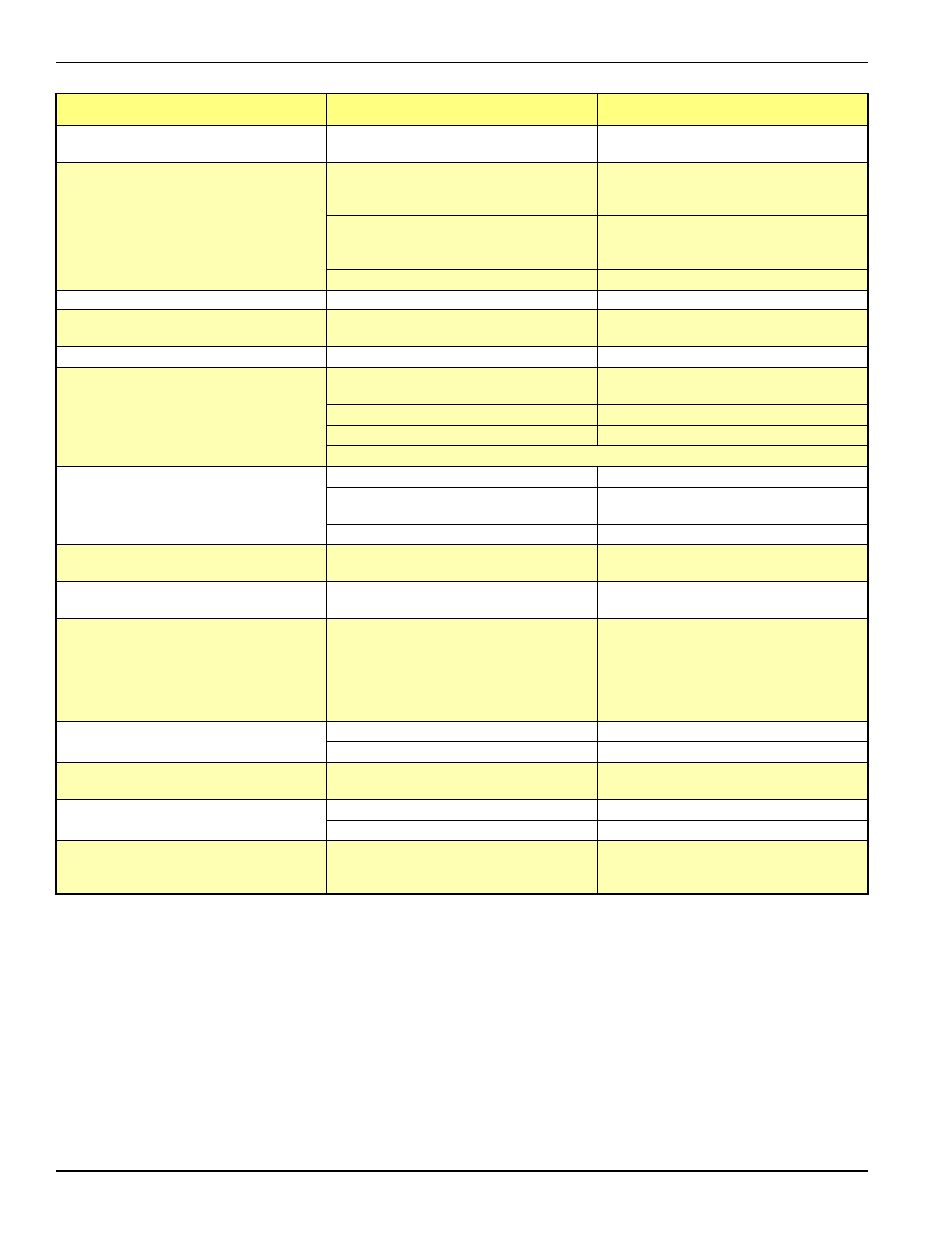

TROUBLESHOOTING GUIDE

WHEEL BEARING FAILURE

Triple-lip seals not installed correctly

Install seals with the lips pointing outward

away from the hub.

HYDRAULIC - LIFT CYLINDERS NOT

FULLY EXTENDING

Lift cylinders not in phase

Fully extend cylinders and hold hydraulic

lever until all cylinders are fully

extended

Cylinders not installed in proper series

Wing cylinders are smaller diameter than

center cylinders. Reinstall cylinders

properly

Hoses not properly connected

Check hose routing

HYDRAULIC - ENTIRE UNIT SETTLING

Depth stop valve not working

Repair valve

HYDRAULIC - UNIT SETTLING, ONE

WING RAISING

Center frame cylinder leaking internally on

side of unit that wing is raising

Repair center master cylinder

HYDRAULIC - WING SETTLING

Wing cylinder leaking

Repair cylinder

DISC GANG PLUGGING

Scrapers set too far from disc blade

Adjust scrapers to meet disc blade closer

and evenly

Operating depth too deep

Raise unit

Conditions too wet

Wait until conditions more favorable

In drier conditions, set scraper farther away from disc blade to improve residue flow

DISC GANG WILL NOT TURN OR

PUSHES SOIL

Scrapers set too tight

Readjust scrapers

Depth set too deep for loose or wet

conditions

Raise implement or wait until conditions

are more favorable

Gang bearing failure

Replace bearing

DISC GANG BEARING SNAP RING

POPS OUT

Gang bearings installed incorrectly

Install bearings with snap ring away from

concave side of disc blade

SCRAPERS BUILD UP WITH

EXCESSIVE SOIL/RESIDUE

Scrapers set too far from disc blade

Readjust scrapers

DISC BLADES LOOSE AND/OR

SHEARING ROLL PIN

Gang not tightened properly

Retighten gang shafts to 1250-1500 ft-lbs.

If gangs have ran loose, gangs may

require disassembly to remove soil to

properly torque gang shafts. Replace

any worn components, shafts/spools,

etc.

HARROW PLUGGING

Harrow height set too low

Raise harrow height.

Tine angle too steep

Use lower tine tooth angle

HARROW BUNCHING RESIDUE

Harrow too aggressive

Use lower tine tooth angle and/or raise

harrow

HARROW DRAGS GROUND WHEN

TRANSPORTING

Operating depth set too low

Raise harrow height

Disc leveler linkage not set correctly

Reposition in lower leveler hole

LIGHTS DO NOT WORK

Harness or lamp connection unplugged

Check all harness/lamp connections to

verify that everything is properly

connected.

PROBLEM

PROBABLE CAUSE

SOLUTION