3 process data mapping for cyclic data transfer, 1 read process data (plc ® leak detector), Read process data (plc – INFICON HLD6000 Refrigerant Leak Detector Interface Description User Manual

Page 31: 1 read process data (plc, Leak detector)

31

Fi

eldb

us C

ommu

nica

tio

n

4.3

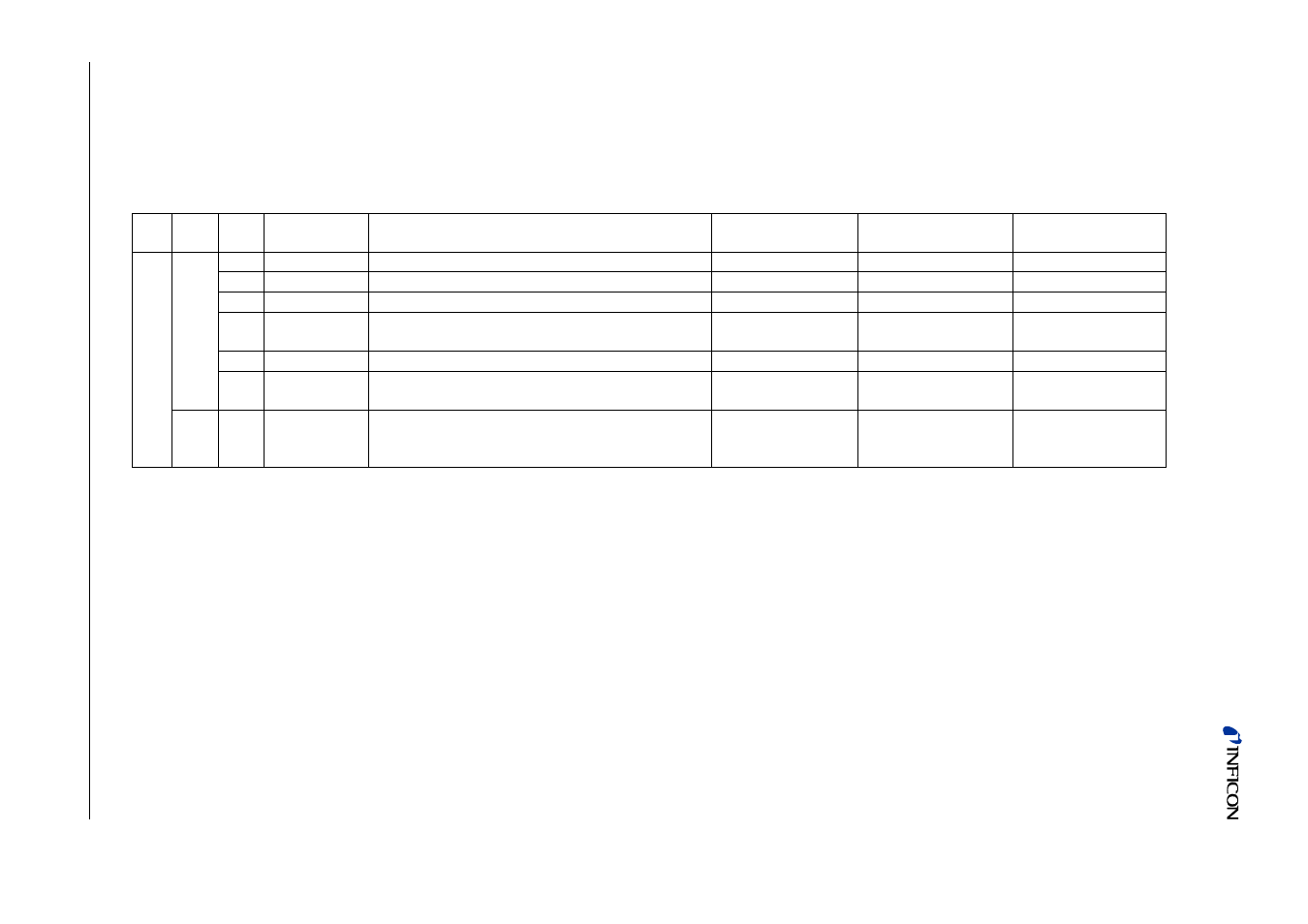

Process Data Mapping for Cyclic Data Transfer

4.3.1

Read Process Data (PLC

Leak Detector)

This data word (2 Bytes) is send periodically from the field bus master (e.g. programmable logic controller) to the leak

detector:

PROFIBUS and PROFINET IO receive high byte first, DeviceNet and EtherNet/IP receive low byte first.

Attention:

If you want to use "Valid setpoint" function via fieldbus please make sure, that the "probe key configuration" ist set to "off".

Title Byte

Bit

Name

Meaning

Similar to PLC

Input

Similar to RS232

ASCII cmd.

Similar to RS232

LD cmd.

co

ntrol word

1

(low

byte)

0

Start

Transition 0->1: Switch from standby to measure

Start

*Start

1

1

Stop

Transition 0->1: Switch from measure to standby

Stop

*Stop

2

2

Clear

Transition 0->1:Clears errors and warnings

Clear

*CLS

5

3

Valid setpoint

Transition 0->1: Switch to Setpoint 2

Transition 1->2: Switch to Setpoint 1

4...6

not used

reserved for further use

7

Cal_extern

Transition 0->1: Start external calibration

Transition 1->0: Acknowledge

*CAL

4

2

(high

byte)

0...7

not used

reserved for further use