Read process data (leak detector, 2 read process data (leak detector, Plc) – INFICON LDS3000 Modular Leak Detector Interface description User Manual

Page 50

50

Fieldbus Communication

Information The PROFIBUS-DP protocol is subject to change. If you are using this

protocol, please ask INFICON for an update.

6.3.2

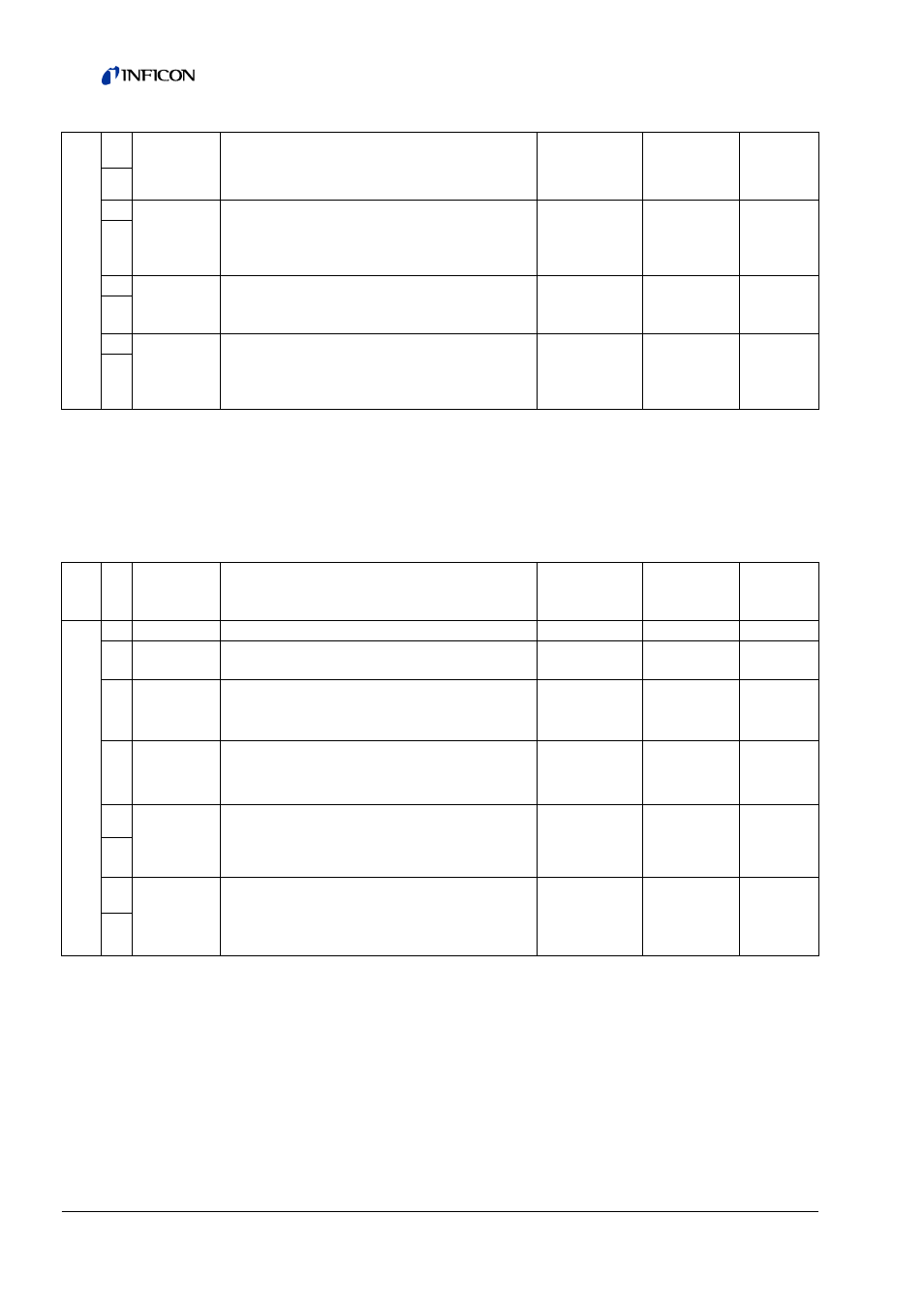

Read Process Data (Leak Detector

PLC)

This data is sent periodically from the leak detector to the programmable logic cont-

roller:

2

0

Gas ballast

Transition 0 -> 1: 0x01 = Gasballast on

Transition 1 -> 0: 0x00 = Gasballast off (if

Gasballast mode != GASBALLAST_ON)

Gasballast

1

2

Zero mode

0 = normal

0x04 = 1 ... 2 dec.

0x08 = 2 ... 3 dec.

0x0C = 19/20 part of the value

3

4

CAL mode

0 = external CAL

0x10 = dyn. CAL

0x20…0x30 = not used

Select dyn/

norm

5

6

Sniff/Vac

0 = Vacuum

0x40 = Sniff

0x80 = according to PLC-Input

0xC0 = not used

Sniff

*CONFIG:M

ODE

401

7

Byte Bit Name

Meaning

Similar to

PLC Output

Similar to

RS232 ASCII

cmd.

Similar to

RS232 LD

cmd.

1

0

(not used)

always 1

1

Zero active

0 = off

0x02 = on

ZERO active

*STATUS:ZE

RO?

2

Error

0 = no error

0x04 = error

Error

Status

word

3

Warning

0 = no warning

0x08 = warning

Warning

Status

word

4

State

internal

calibration

0 = inactive

0x10 = active

0x20/0x30 = not used

CAL active

*STATUS:C

AL?

260

5

6

State

external

calibration

0 = inactive

1 = 0x40 = active

2 = 0x80 = waiting for test leak closed

3 = 0xC0 = not used

CAL active

*STATUS:C

AL?

260

7