Operation - fence components – INCRA Miter 5000 with Sled & Telescoping Fence User Manual

Page 6

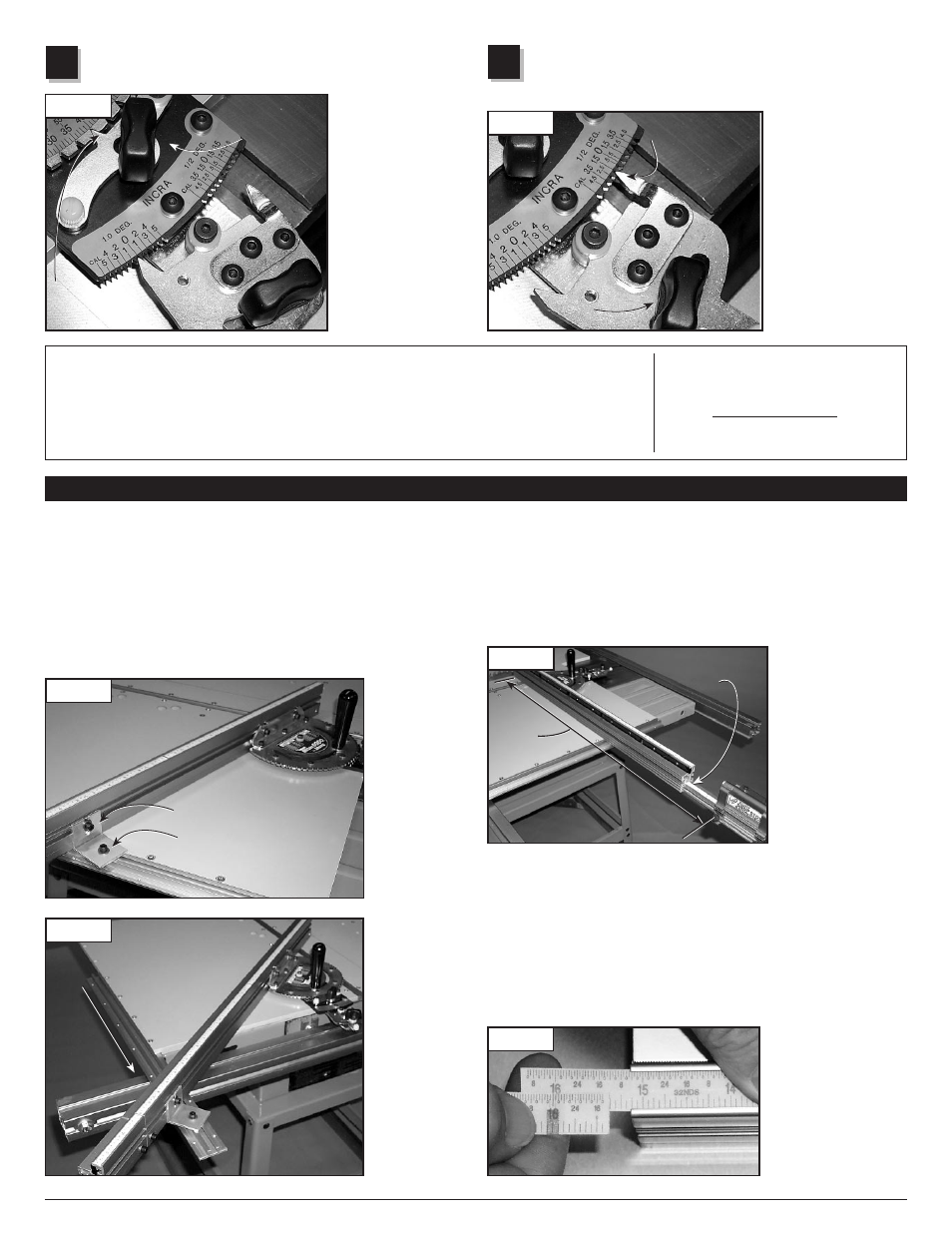

Loosen the rear actuator thumbscrew. Use the left-hand tooth

to add or subtract from the coarse adjustment setting in 1°

intervals. Use the right-hand tooth to add or subtract from the

coarse adjustment

setting in

1

⁄

2

° intervals.

Engage the tooth

firmly in the selected

notch, then tighten the

large clamping knob

and the rear actuator

thumbscrew,

Fig.-21.

Important: After

completing your cut,

return the rear actuator

setting to the 0° notch.

Fence extender

For stopped cuts beyond the 32" range of the standard fence, clamp

the INCRA Flip Shop Stop to the 4" fence extender. Now loosen the

1

⁄

4

-20 socket head screw located at the left end of the 32" fence and

slide the 4" fence extender to the left. Tighten the fastener when

you reach the desired scale reading. To set the scales for accurate

readout, set the protractor to the desired angle, then measure the

distance between

the blade and the

stop surface on the

flip arm. Slide the

scale to read this

measurement directly

under the end of the

32" fence,

Fig.-24.

Slide the extender

bar out to also adjust

the overlapping scale.

Outboard Fence lock

For heavy duty applications, use the outboard fence lock to provide

rock solid support for the left end of the fence. To make a change to

your fence angle, first loosen both

1

⁄

4

-20 fasteners that secure the

outboard fence lock to the fence and Left Sled Base.

Adjust the angle at the protractor head as previously described and

tighten the thumbscrews and large clamping knob. Now tighten

the fastener that secures the outboard fence lock to the back of the

fence. Finally,

tighten the

fastener that

secures the

outboard

fence lock to

the Left Sled

Base,

Fig.-22.

To use the

outboard

fence lock for

angle settings

that pivot the

fence off of

the left rear

corner of the

sled base,

you can shift

the position of

the gold panel

connector.

Just remove

the fasteners

and shift

the panel

connector

back 3 or 4

holes,

Fig.-23.

2nd Engage right or

left-hand tooth to

add or subtract

1

⁄

2

° increment

3rd Tighten

large clamping

knob and rear

actuator

thumb-

screw

1/2

° Indexing

Loosen the large clamping knob. Loosen the front actuator

thumbscrew and

pivot the actuator

tooth away from the

notches located on

the protractor head.

Rotate the protractor

head and engage

the front actuator

tooth at the 5° notch

closest to the angle

you want. Tighten

the front actuator

thumbscrew,

Fig.-20.

1st Loosen large

clamping knob

3rd Tighten

thumbscrew

about your Fence scales

All INCRA products use overlapping 16" long Lexan scales. The

overlap allows fine-tuning the scale from one end to the other to

agree with the high degree of accuracy provided by the INCRA saw

toothed positioning racks. These scales are printed in 16" lengths

(0-16", 16-32", 32-48" etc.). As they are slid into the scale slot on

the fence, the ends are overlapped and aligned using the optical

window located at the end of the second scale,

Fig.-25. The friction

fit will keep the scales in place. If you wish, you can use a small

piece of double faced

tape at the overlap to

ensure that the scales

move together when

changing your zeroed

setups for mitering.

FIG. 25

Operation - Fence Components

FIG. 22

Fig. 24

FIG. 23

Continuous adjustments –

For angle settings finer than the

1

⁄

2

° settings, first use the

1

⁄

2

° indexing instructions above to locate the protractor head as close as possible to the desired

angle. With the large clamping knob loosened, pivot the rear actuator tooth slightly away from

the notch on the

1

⁄

2

° adjustment plate. Rotate the protractor head in the direction of required

adjustment and tighten the large clamping knob. Do not tighten the rear actuator thumbscrew. As

with any mitering tool, odd angle adjustments may require a little trial and error.

Caution:

After making any adjustments to the

miter angle of your INCRA Miter5000,

always verify safe clearance between

the fence and the blade before

turning on the saw.

2

1

FIG. 21

FIG. 20

1st Loosen large

clamping knob

3rd Tighten

thumbscrew

2nd Loosen front actuator

thumbscrew and engage tooth with 5°

notch closest to your desired angle

2nd Loosen front actuator

thumbscrew and engage tooth with 5°

notch closest to your desired angle

1st Loosen rear

actuator thumbscrew

1st Loosen rear

actuator thumbscrew

2nd Engage right or

left-hand tooth to

add or subtract

1

⁄

2

° increment

3rd Tighten

large clamping

knob and rear

actuator

thumb-

screw

Always tighten first

Always tighten second

Always tighten first

Always tighten second

Panel connector

can be shifted to

provide support

Panel connector

can be shifted to

provide support

Slide scale

to read

blade to stop

measurement

Read

scale

here

Read

scale

here

Slide scale

to read

blade to stop

measurement

6