INCRA Miter 5000 with Sled & Telescoping Fence User Manual

Page 4

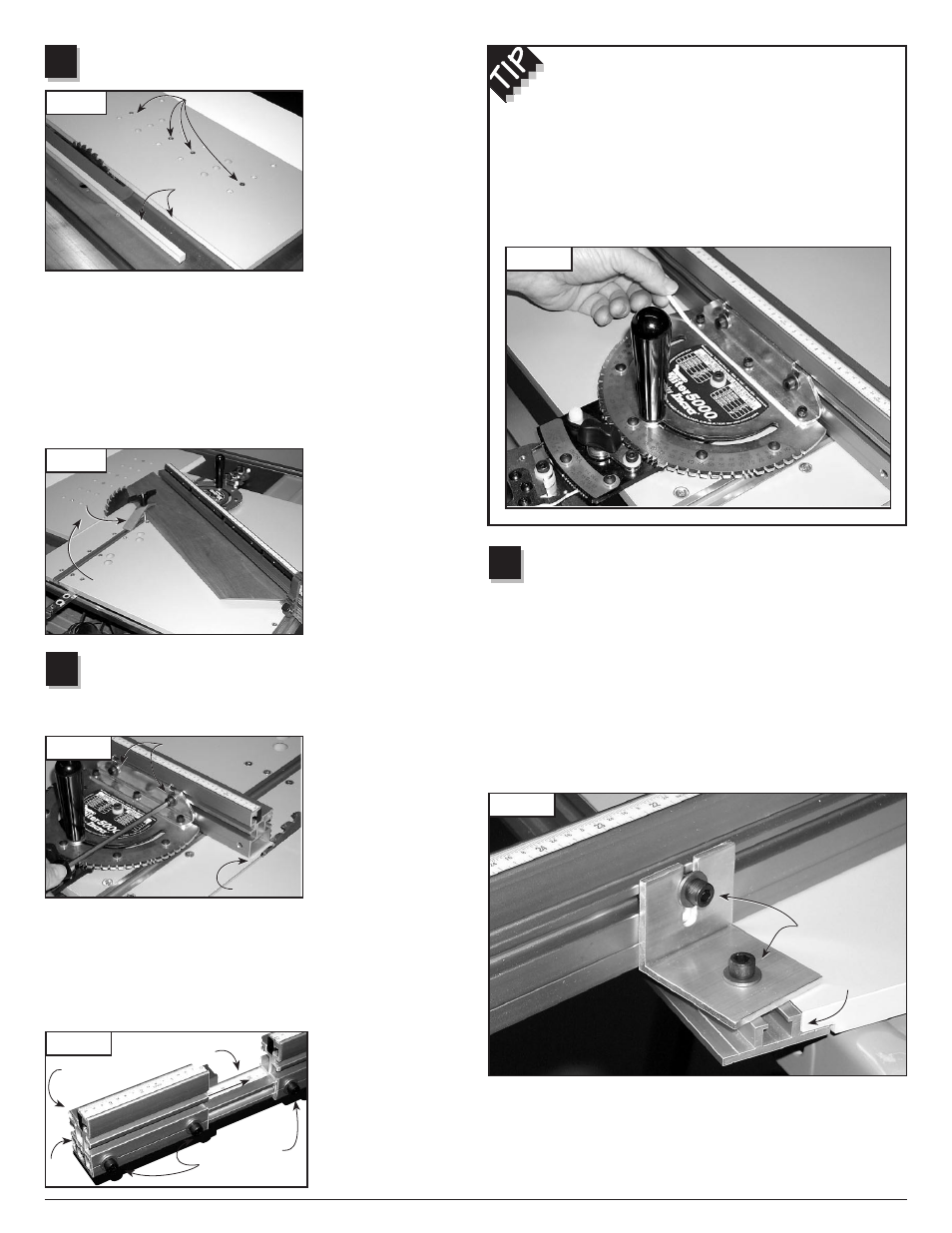

attach remainder of right sled Base and

Cut Off Overhang

Using (4) #10-24 x

3

⁄

4

"

phillips flat head screws,

attach the remainder of

the Right Sled Base to

the aluminum miter bar.

Use the row of mounting

holes that permit the

least amount of overhang

beyond the left side of

the saw blade. Raise the

saw blade about

3

⁄

4

" and

make a cut to remove the

portion of the Right Sled Base that extends beyond the left side of the

blade,

Fig.-8. Turn off the saw, lower the blade and return the Left Sled

Base to the table saw.

In use, only the Left Sled Base slides to move your workpiece through

a cut. The Right Sled Base will be positioned adjacent to the blade

and locked in place by tightening the (2) expansion mechanisms

to provide zero clearance and workpiece cutoff support,

Fig. 9.

Additional Right Base Panels can be purchased and cut as described

above with the blade

tilted for zero clearance

support during compound

mitering. Just mark

each of the panel parts

with the blade tilt angle

for future reference.

Optional hold down

clamps can be attached

into the panel connector

T-slot as shown.

attach Fence and Fence extender

to left sled Base

Note: Miter3000 to Miter5000 Conversion Kits do not include

Fence Extender components.

Open

Hardware Pack

C-08 and using (2)

1

⁄

4

-

20 x

1

⁄

2

" socket head

screws with washers

and rectangular nuts,

attach the fence to the

fence mounting bracket.

Slide the fence to a

position that leaves safe

clearance between the

fence and blade, then tighten the (2) fasteners,

Fig.

-

10.

Loosely install (1)

1

⁄

4

-20 x

3

⁄

8

" socket head fastener with washer

and rectangular nut to the left end of the fence and slide extender

bar into fence with the scale face up. (The higher numbers on the

scale should go in first.) Loosely install (2)

1

⁄

4

-20 x

3

⁄

8

" socket head

screws with washers and rectangular nuts to the 4" fence extender

and slide onto the end

of the extender bar.

Position the 4" fence

extender flush with the

end of the extender

bar and tighten all (3)

fasteners,

Fig 11.

clearance

Cut to

remove

left side

overhang

attach Outboard Fence lock

Loosen the large clamping knob, disengage the front actuator

and pivot the fence just over the left rear corner of the sled

base, about 20°. Loosely install (1)

1

⁄

4

-20 x

1

⁄

2

" socket head screw

with washer and rectangular nut through the hole in the outboard

fence lock. Slide the remaining

1

⁄

4

-20 x

1

⁄

2

" socket head screw with

washer and rectangular nut into the T-slot on the back of the fence.

Slide the slotted end of the outboard fence lock under the washer

on the fence fastener, then slide the rectangular nut of the other

fastener into the T-slot on the gold panel connector,

Fig.-13. Rotate

the fence to engage the front actuator with the 0° notch on the

protractor head. Tighten the front actuator thumbscrew then tighten

the large clamping knob.

8

7

FIG. 10

FIG. 11

FIG. 12

FIG. 13

In operation, after setting the protractor head angle and tightening

the large clamping knob, you must tighten the outboard lock to the

fence before tightening to the sled base. Try setting a few angles to

get the hang of it, then leave both outboard lock fasteners loose as

you continue with the final calibration.

6

FIG. 8

FIG. 9

squaring the fence to your sled base

The method used to join the fence mounting bracket to

the protractor head makes it easy to fine-tune the fence

perfectly perpendicular to your sled base. To adjust, loosen

the (3) #10-24 socket head screws that secure the bracket

and slide a paper or plastic shim between the bracket and the

protractor head,

Fig.-12. Placing the shim behind the screws

will

decrease the angle. Placing the shim in front of the

screws will

increase the angle.

#10-24 x

3

⁄

4

"

phillips flat head

screws

Cut to

remove

left side

overhang

Always lock Right

Base in place by

tightening expansion

mechanisms

clearance

1

⁄

4

"-20 x

3

⁄

8

"

socket head

screws

4" fence

extender

Extender bar

1

⁄

4

"-20 x

1

⁄

2

"

socket head

screws

Optional

hold down

clamp

1

⁄

4

-20 x

1

⁄

2

"

socket head

screws

1

⁄

4

-20 x

1

⁄

2

"

socket head

screws

Panel

connector

#10-24 x

3

⁄

4

"

phillips flat head

screws

Flush

here

Always lock Right

Base in place by

tightening expansion

mechanisms

4