HMC Electronics 29309 Loctite E-90FL Hysol 2-Part Epoxy Adhesive, Flexible, High Performance User Manual

Page 2

TDS Hysol

®

E-90FL™, December

-

2006

Block Shear Strength, ISO 13445:

PVC

N/mm² 6.5

(psi) (940)

ABS

N/mm² 5.0

(psi) (730)

Epoxy

N/mm² 12.2

(psi) (1,770)

Acrylic

N/mm² 3.0

(psi) (440)

Glass

N/mm² 14.6

(psi) (2,120)

Cured for 2 hours @ 65 °C

Lap Shear Strength, ISO 4587:

Aluminum (acid etched), 0.13 mm

gap

N/mm² ≥3.4

LMS

(psi) (≥493)

TYPICAL ENVIRONMENTAL RESISTANCE

Cured for 12 hours @ 65 °C followed by 4 hours @ 22 °C

Lap Shear Strength, ISO 4587:

Aluminum (acid etched & abraded), 0.1 to 0.2 mm gap

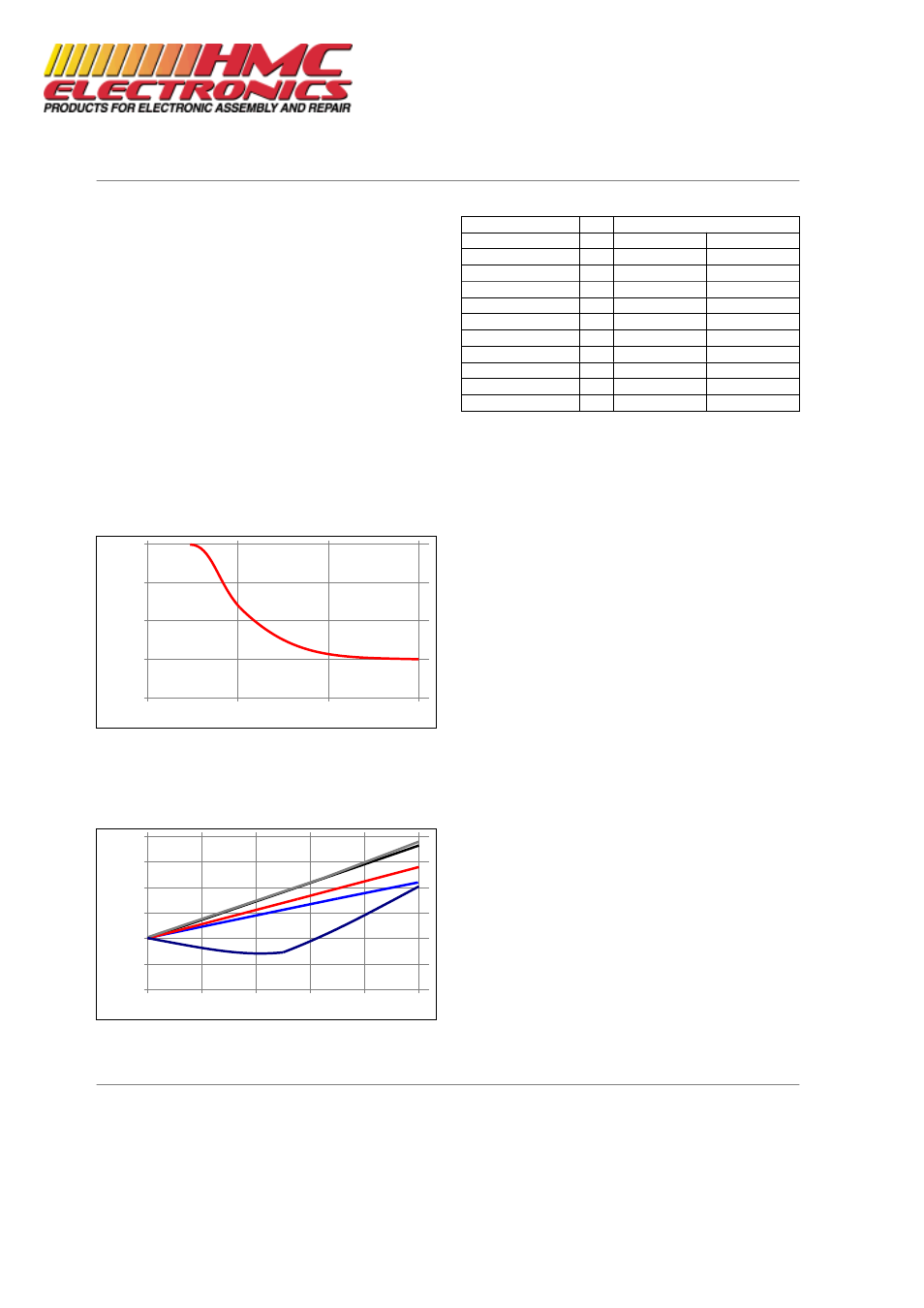

Hot Strength

Tested at temperature

% Strength @ 22 °C

Temperature, °C

100

75

50

25

0

0

50

100

150

Cured for 5 days @ 22 °C

Lap Shear Strength, ISO 4587:

Steel

Heat Aging

Aged at temperature indicated and tested @ 22 °C

% Initial Strength @ 22 °C

Exposure Time, hours

300

250

200

150

100

50

0

0

200

400

600

800

1000

177 °C

150 °C

66 °C

120 °C

93 °C

Chemical/Solvent Resistance

Aged under conditions indicated and tested @ 22 °C.

% of initial strength

Environment

°C

500 h

1000 h

Air

87

---

151

Motor oil (10W30)

87

172

212

Unleaded gasoline

87

91

66

Water/glycol 50/50

87

57

83

Salt fog

22

---

60

95% RH

38

---

68

Condensing Humidity

49

---

70

Water

22

---

85

Acetone

22

30

0

Isopropanol

22

83

67

GENERAL INFORMATION

This product is not recommended for use in pure oxygen

and/or oxygen rich systems and should not be selected as

a sealant for chlorine or other strong oxidizing materials.

For safe handling information on this product, consult the

Material Safety Data Sheet (MSDS).

Directions for use

1. For high strength structural bonds, remove surface

contaminants such as paint, oxide films, oils, dust, mold

release agents and all other surface contaminants.

2. Use gloves to minimize skin contact. DO NOT use

solvents for cleaning hands.

3. Dual Cartridges: To use simply insert the cartridge into

the application gun and start the plunger into the cylinders

using light pressure on the trigger. Next, remove the

cartridge cap and expel a small amount of adhesive to be

sure both sides are flowing evenly and freely. If automatic

mixing of resin and hardener is desired, attach the mixing

nozzle to the end of the cartridge and begin dispensing

the adhesive. For hand mixing, expel the desired amount

of the adhesive and mix thoroughly. Mix for approximately

15 seconds after uniform color is obtained.

Bulk Containers: Mix thoroughly by weight or volume in

the proportions specified in Product Description section.

Mix vigorously, approximately 15 seconds after uniform

color is obtained.

4. For maximum bond strength apply adhesive evenly to

both surfaces to be joined.

5. Application to the substrates should be made within 90

minutes. Larger quantities and/or higher temperatures

will reduce this working time.

6. Join the adhesive coated surfaces and allow to cure at

25 °C for 24 hours for high strength. Heat up to 93 °C, will

speed curing.

7. Keep parts from moving during cure. Contact pressure is

neccesary. Maximum shear strength is obtained with a 0.1

to 0.2 mm bond line.

8. Excessive uncured adhesive can be cleaned up with

ketone type solvents.

Henkel Loctite Americas

+860.571.5100

Henkel Loctite Europe

+49.89.9268.0

Henkel Loctite Asia Pacific

+81.45.758.1810

For the most direct access to local sales and technical support visit: www.loctite.com

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

(800) 482-4440