HMC Electronics 29309 Loctite E-90FL Hysol 2-Part Epoxy Adhesive, Flexible, High Performance User Manual

Hysol, E-90fl

Technical Data Sheet

Hysol

®

E-90FL™

December

-

2006

PRODUCT DESCRIPTION

Hysol

®

E-90FL™

provides

the

following

product

characteristics:

Technology

Epoxy

Chemical Type (Resin) Epoxy

Chemical Type

(Hardener)

Polyamide

Appearance (Resin)

Off-white to beige liquid

LMS

Appearance (Hardener) Dark gray liquid

LMS

Appearance (Mixed)

Gray, opaque solid

LMS

Components

Two component - requires mixing

Viscosity

Medium

Mix Ratio, by volume -

Resin : Hardener

1 : 1

Mix Ratio, by weight -

Resin : Hardener

100 : 85

Cure

Room temperature cure after mixing

Application

Bonding

Hysol

®

E-90FL™ is a toughened, medium viscosity, industrial

grade epoxy adhesive with extended working life. Once mixed,

the two component epoxy cures at room temperature to form a

flexible, gray bondline with excellent resistance to shock and

impact. When fully cured, the epoxy is resistant to a wide range

of chemicals and solvents, and acts as an excellent electrical

insulator. Typical applications include bonding plastic, metal,

glass, wood, ceramic, rubber, and masonry materials where

flexibility is required. Suited for low-stress, high-impact bonding

applications of dissimilar materials. Hysol

®

E-90FL™ can also

be used for repairing strain gauges, sealing seams on

fiberglass components, repairing printed circuit boards,

bonding stainless steel inserts, and rubber hose to steel tubing.

The products extended working life allows more time to adjust

parts during assembly.

TYPICAL PROPERTIES OF UNCURED MATERIAL

Resin:

Specific Gravity @ 25 °C

1.3

Flash Point - See MSDS

Viscosity, Brookfield - RVT, 25 °C, mPa·s (cP):

Spindle 7, speed 10 rpm

62,000 to 81,000

LMS

Hardener:

Specific Gravity @ 25 °C

1.1

Flash Point - See MSDS

Viscosity, Brookfield - RVT, 25 °C, mPa·s (cP):

Spindle 6, speed 10 rpm

10,000 to 28,000

LMS

Mixed:

Specific Gravity @ 25 °C

1.2

Working life, minutes

90

Tack Free Time minutes

300

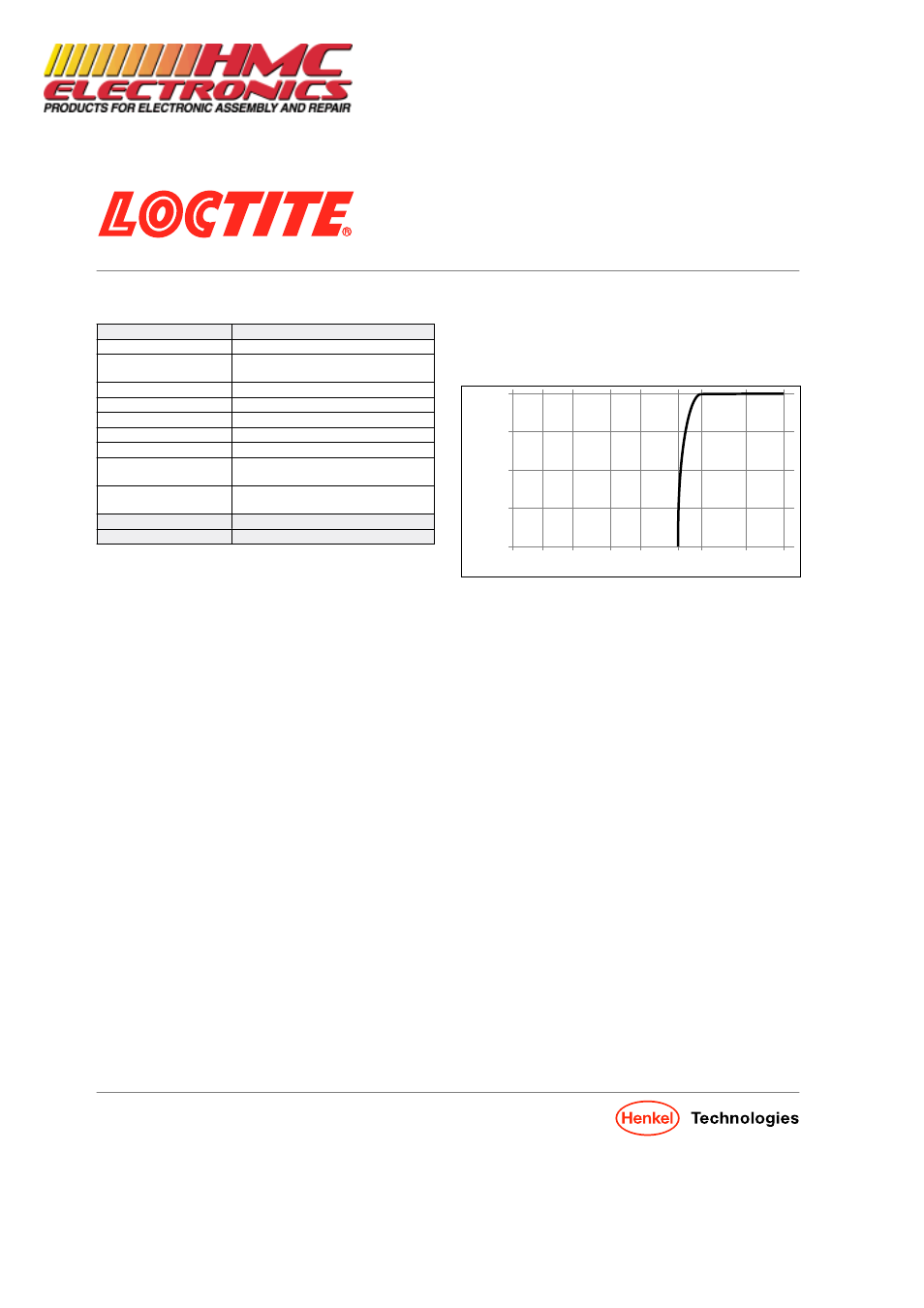

TYPICAL CURING PERFORMANCE

Cure Speed vs. Time

The graph below shows shear strength developed with time on

abraded, acid etched aluminum lapshears @ 25 °C with an

average bondline gap of 0.1 to 0.2 mm and tested according to

ISO 4587.

% of Full Strength on Alumin.

Cure Time

100

75

50

25

0

1min 5min 10min 30min 1h

3h 6h

24h

72h

TYPICAL PROPERTIES OF CURED MATERIAL

Cured @ 25 °C

Physical Properties:

Glass Transition Temperature (Tg), °C

30

Shore Hardness, ISO 868, Durometer D

60

Elongation, ISO 527-2, %

64

Tensile Strength, ISO 527-2

N/mm² 13

(psi) (1,900)

Electrical Properties:

Dielectric Breakdown Strength, IEC 60243-1, kV/mm 16

TYPICAL PERFORMANCE OF CURED MATERIAL

Adhesive Properties

Cured for 5 days @ 22 °C

Lap Shear Strength, ISO 4587:

Steel (grit blasted)

N/mm² 5.6

(psi) (810)

Aluminum (acid etched & abraded),

0.1 to 0.2 mm gap

N/mm² 21.6

(psi) (3,130)

Aluminum (anodised)

N/mm² 10.8

(psi) (1,570)

Stainless steel

N/mm² 6.7

(psi) (970)

Polycarbonate

N/mm² 5.0

(psi) (720)

Nylon

N/mm² 2.4

(psi) (350)

Wood (Fir)

N/mm² 7.9

(psi) (1,150)

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

(800) 482-4440