HMC Electronics 62040 Loctite 620 Retaining Compound, High Temperature User Manual

Page 2

TDS LOCTITE

®

620, May

-

2004

TYPICAL PROPERTIES OF CURED MATERIAL

Physical Properties:

Coefficient of Thermal Expansion, ASTM D 696, K

-1

80×10

-6

Coefficient of Thermal Conductivity, ASTM C 177,

W/(m·K)

0.10

Specific Heat, kJ/(kg·K)

0.30

Elongation, at break, ASTM D 412, %

<1

TYPICAL PERFORMANCE OF CURED MATERIAL

Adhesive Properties

After 24 hours @ 22 °C

Compressive Shear Strength, ISO 10123:

Steel pins and collars

N/mm² ≥17.20

LMS

(psi) (2,495)

Cured for 24 hours @ 22 °C, followed by 24 hours @ 177 °C,

tested @ 22 °C

Compressive Shear Strength, ISO 10123:

Steel pins and collars

N/mm² ≥24.10

LMS

(psi) (3,495)

TYPICAL ENVIRONMENTAL RESISTANCE

Cured for 1 week @ 22 °C

Compressive Shear Strength, ISO 10123:

Steel pins and collars

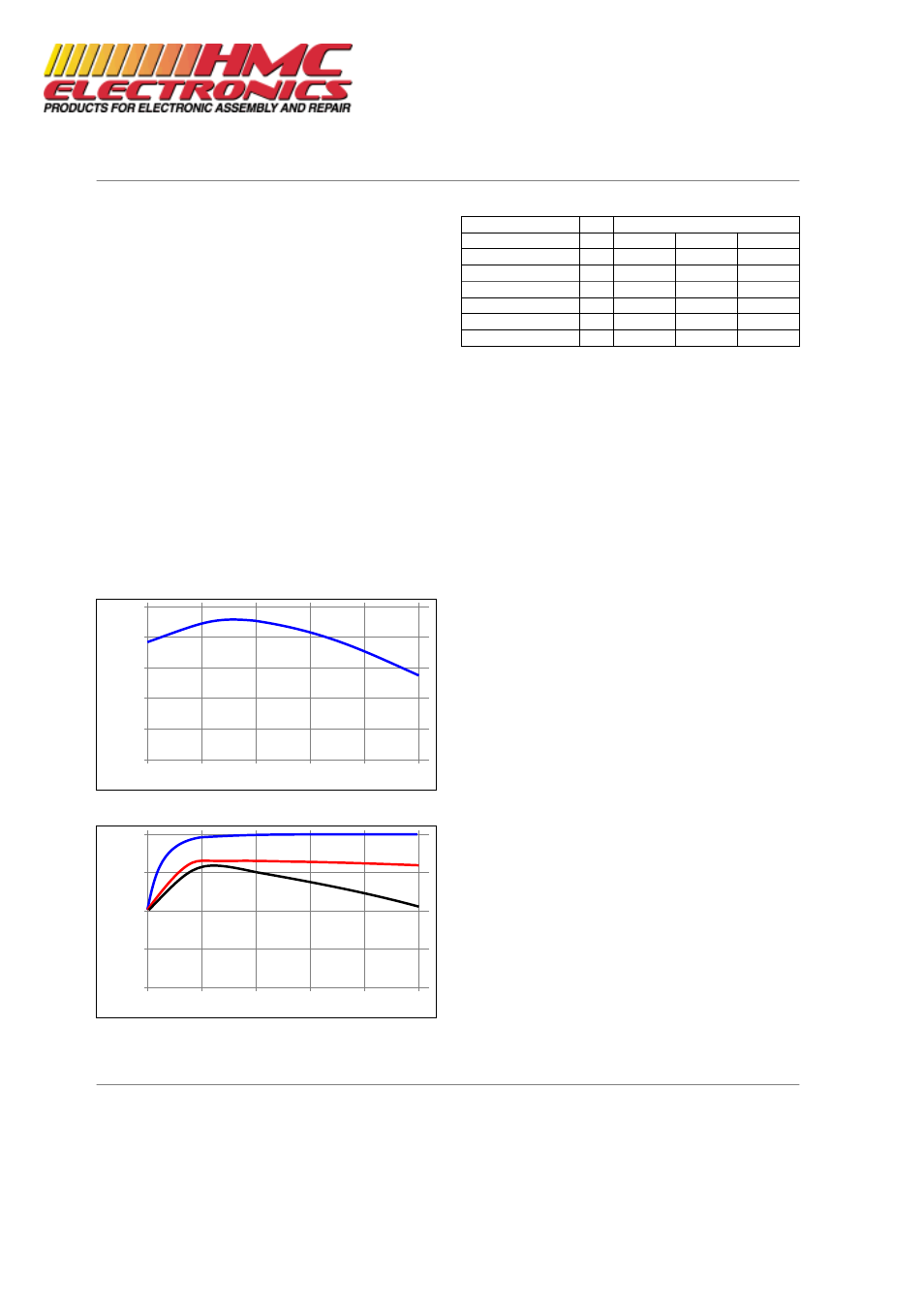

Hot Strength

Tested at temperature

% RT Strength

Temperature, °C

125

100

75

50

25

0

0

50

100

150

200

250

Heat Aging

Aged at temperature indicated and tested @ 22 °C

% Initial Strength at RT

Hours

200

150

100

50

0

0

100

500

1000

3000

5000

120°C

150°C

180°C

Chemical/Solvent Resistance

Aged under conditions indicated and tested @ 22 °C.

% of initial strength

Environment

°C

100 hr

500 hr

1000 hr

Motor Oil

125

100

100

100

Unleaded Petrol

22

95

95

95

Brake fluid

22

100

100

100

Water Glycol 50/50

87

95

80

80

Ethanol

22

100

100

75

Acetone

22

95

95

95

GENERAL INFORMATION

This product is not recommended for use in pure oxygen

and/or oxygen rich systems and should not be selected as

a sealant for chlorine or other strong oxidizing materials.

For safe handling information on this product, consult the

Material Safety Data Sheet (MSDS).

Where aqueous washing systems are used to clean the

surfaces before bonding, it is important to check for

compatibility of the washing solution with the adhesive. In

some cases these aqueous washes can affect the cure and

performance of the adhesive.

This product is not normally recommended for use on plastics

(particularly thermoplastic materials where stress cracking of

the plastic could result). Users are recommended to confirm

compatibility of the product with such substrates.

Directions for use

For Assembly

1. For best results, clean all surfaces (external and internal)

with a Loctite cleaning solvent and allow to dry.

2. If the material is an inactive metal or the cure speed is to

slow, spray with Activator 7471 or 7649 and allow to dry.

3. Shake the product thoroughly before use.

4. For Slip Fitted Assemblies, apply adhesive around the

leading edge of the pin and the inside of the collar and

use a rotating motion during assembly to ensure good

coverage.

5. For Press Fitted Assemblies, apply adhesive thoroughly

to both bond surfaces and assemble at high press on

rates.

6. For Shrink Fitted Assemblies the adhesive should be

coated onto the pin, the collar should then be heated to

create sufficient clearance for free assembly.

7. Parts should not be disturbed until sufficient handling

strength is achieved.

For Disassembly

1. Apply localized heat to the assembly to approximately 250

°C. Disassemble while hot.

For Cleanup

1. Cured product can be removed with a combination of

soaking in a Loctite solvent and mechanical abrasion

such as a wire brush.

Henkel Loctite Americas

+860.571.5100

Henkel Loctite Europe

+49.89.9268.0

Henkel Loctite Asia Pacific

+81.45.758.1810

For the most direct access to local sales and technical support visit: www.loctite.com

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

(800) 482-4440