Engine maintenance schedule – ERICO SBG200 ERICO RAIL GRINDER User Manual

Page 10

5

www.erico.com

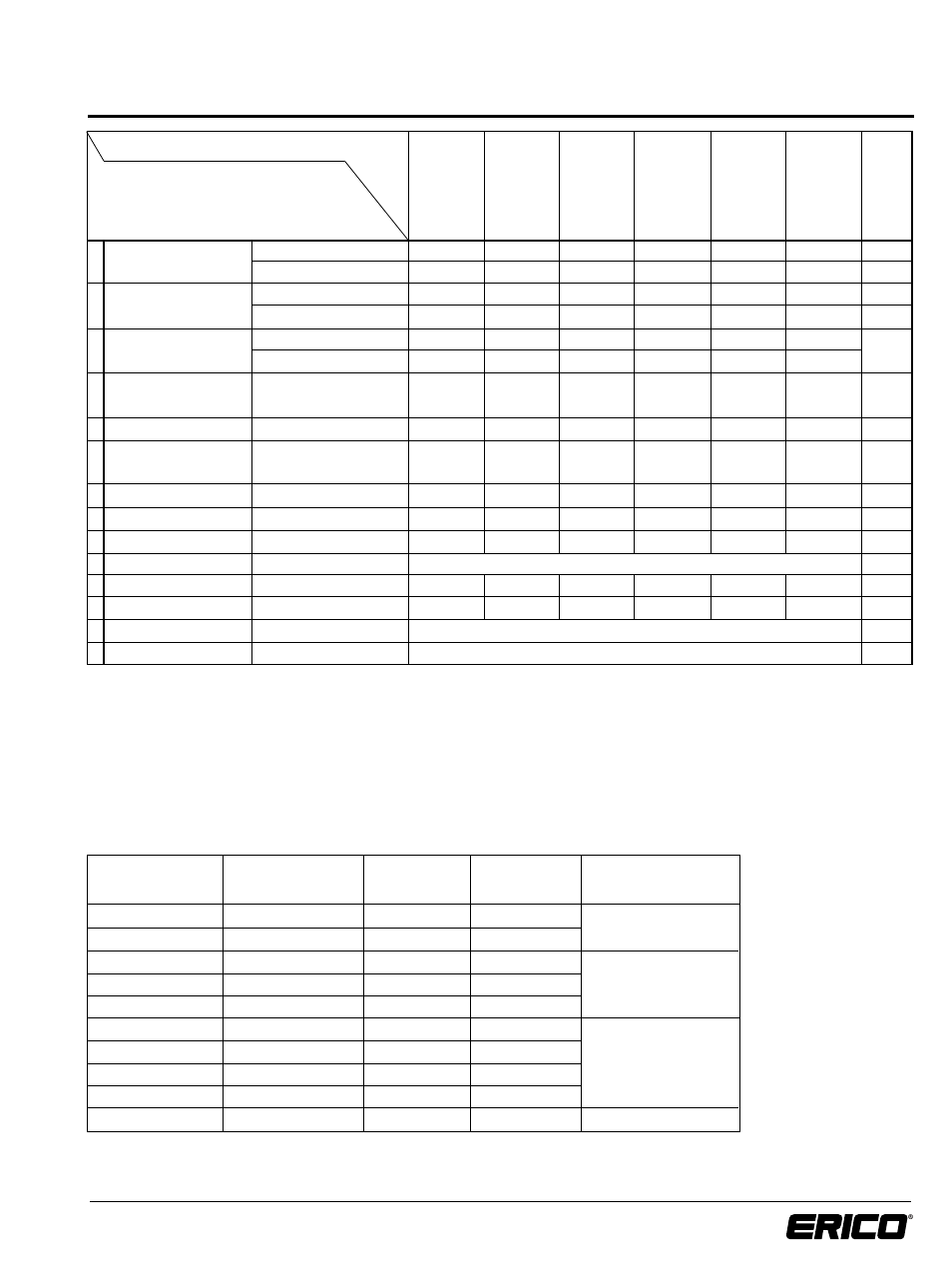

ENGINE MAINTENANCE SCHEDULE

REGULAR SERVICE PERIOD (3)

ITEM

Perform at every indicated

month or operating hour

interval, whichever comes first.

Each use

First

month or

10 hours

Every

3 months

or

25 hours

Every

6 months

or

50 hours

Every

year

or

100 hours

Every

2 years

or

300 hours

Refer

to

page

Engine Oil

Air Filter

Spark Plug

Spark Arrester

(optional parts)

Engine Cooling Fins

Nuts, Bolts, Fasteners

Clutch Shoes

Idle Speed

Valve Clearance

Combustion Chamber

Fuel Filter

Fuel Tank

Fuel Tubes

Oil Tube

Check Level

Change

Check

Clean

Check - Adjust

Replace

Clean

Check

Check

(Retighten if necessary)

Check

Check - Adjust

Check - Adjust

Clean

Check

Clean

Check

Check

27

29

32

33

34

40

37

–

–

–

–

–

38

38

–

–

●

●

●

●

●

●

●

●

●

●

★

★

★

★

★

(1)

★

★

★

(2)

★

★

★

(2)

★

(2)

★

★

★

After every 300 hours (2)

Every 2 years (replace if necessary) (2)

Every 2 years (replace if necessary) (2)

●

Emission-related items.

(1) Service more frequently when used in dusty areas.

(2) These items should be serviced by your servicing dealer, unless you have the proper tools and are mechanically proficient.

Refer to Honda

®

shop manual for service procedures.

(3) For commercial use, log hours of operation to determine proper maintenance intervals.

Pages referenced in the maintenance schedule and trouble shooting chart are in the Honda engine owner’s manual GX2

provided with your SBG200 rail grinder.

ERICO

®

Required

Screw

Part No.

Item No.

Quantity

Torque

3/8-16 x 1

A927D038

12

1

75 in-lbs (8.47 N-m)

1/4-20 x 3/4

A927F179

17

2

M6-1 x 25

A927K029

13

4

M6-1 x 12

A927K097

15

2

45 in-lbs (5.08 N-m)

M5-0.8 x 10

A927K099

38

1

#8-32 x 5/8

A927P028

14

6

#10-32 x 1

SBG20015G

33

2

8 in-lbs (0.90 N-m)

#10-32 x 1

SBG20027G

Sold Separately

2

M3-0.5 x 18

A927K061

42

1

#10-32 x 1/2

A927K098

29

1

60 in-lbs (6.78 N-m)

Torque Chart: SBG200

NOTE:

1. Apply LOCTITE

®

to fasteners prior to tightening. See torque chart for required torque levels.