Enerpac SafeLink User Manual

Page 8

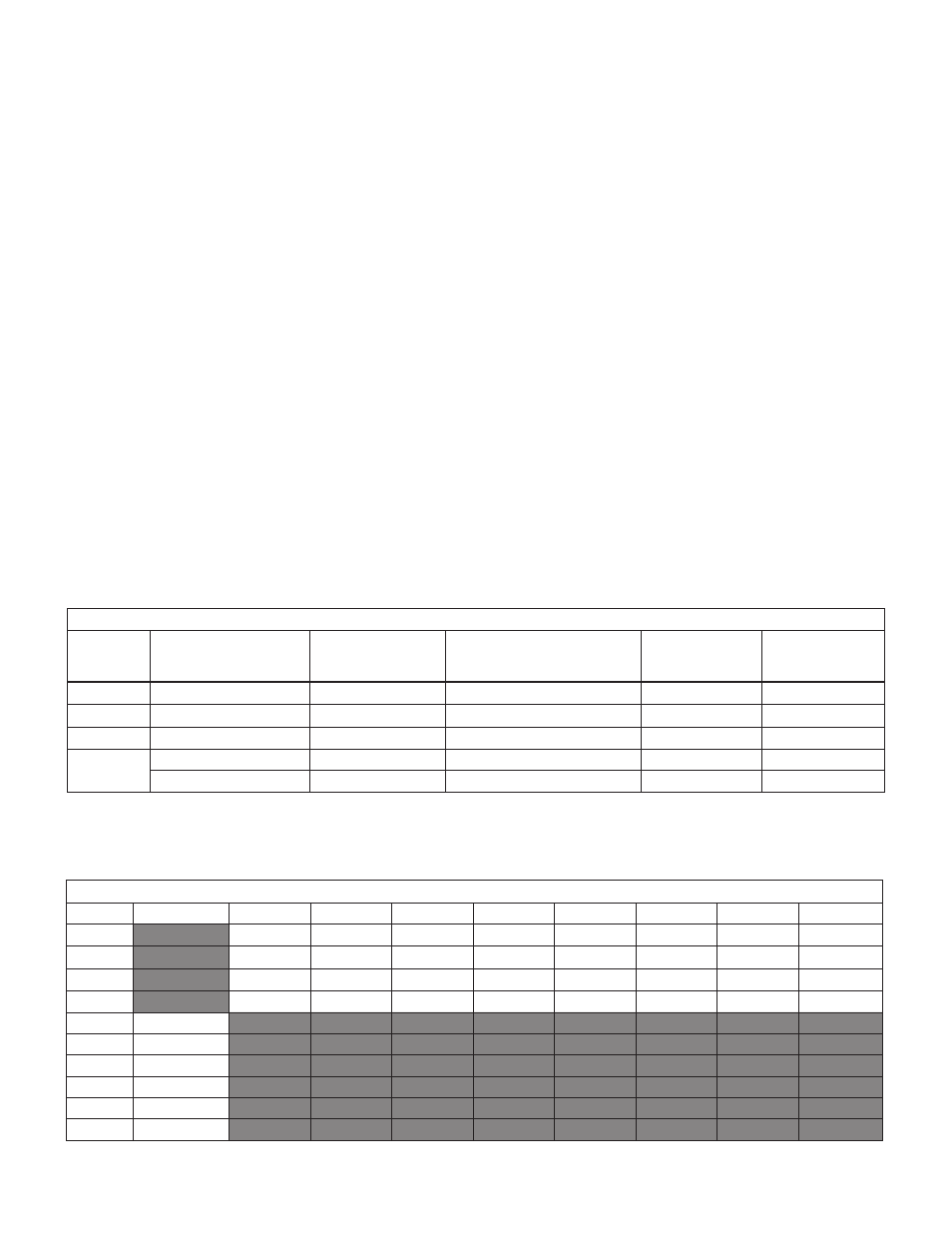

Table 6 - Expanded System Data and Recommendations

Number of

fi xtures:

SafeLink send unit

model number:

Number of outputs

available from each

send unit:

Recommended connection to

machine control:

Output protocol:

Number of

outputs to

machine control:

1

SLS-1, SLS-2 or SLS-3

3

SLR-1 or SLR-2

24 VDC

6

2

SLS-1, SLS-2 or SLS-3

3

SLR-1 or SLR-2

24 VDC

6

3 to 4

SLS-1, SLS-2 or SLS-3

3

SLR-1 or SLR-2 with SLEM-1

24 VDC

12

5 or more

SLS-1, SLS-2 or SLS-3

3

Modbus from SLR-1 or SLR-2

Modbus

47

SLS-1, SLS-2 or SLS-3

3

SLR-1 or SLR-2 with SLEB-1

Ethernet

47

Table 7 - Modbus Holding Registers

I/O Port

Receive #1

Send #1

Send #2

Send #3

Send #4

Send #5

Send #6

Send #7

Send #8

1

17

33

49

65

81

97

113

129

2

18

34

50

66

82

98

114

130

3

19

35

51

67

83

99

115

131

8

24

40

56

72

88

104

120

136

9

9

10

10

11

11

12

12

13

13

14

14

8.6 Removing an SLS Send Unit from the Network

Before taking a fixture out of service or moving it to another

system, the fixture’s SLS send unit must be removed from the

network.

Use the following procedure to unbind an SLS-1, SLS-2 or

SLS-3 send unit from an SLR-1 or SLR-2 receive unit:

Note: Refer to Section 5.0 for button locations.

1. On the SLS send unit, press and hold button #1 for 3 to 4

seconds. This will turn-off the send unit.

2. On the SLR receive unit:

• Check that the display shows “ERROR”.

• Press button #2 once.

Check that the display shows “NOD x”

Note: “x” is the ID number (node) of the SLS send unit that

was turned-off in step 1.

• Press button #2 again.

Check that the display shows “EC 53”.

• Press button #1.

Check that the display shows “CLEAR”.

• Press button #2 to accept the changes.

Check that the display shows “ERASED”.

The SLS send unit should now be unbound from the SLR

receive unit. It will no longer be included in the network.

9.0 SETTING UP EXPANDED SYSTEMS

Refer to Table 6 for an overview of SafeLink expansion

possibilities.

If only one or two additional SLS send units are required, the

SLEM-1 Expansion Unit can be used. For systems requiring

greater numbers of additional SLS send units (such as a pallet

pool system) the interface to the machine control can be

achieved using either the standard 5-Pin serial port connection

located on the SLR receive unit or by using the SLEB-1

Ethernet Bridge. The SLEB-1 allows the SafeLink system to be

connected to an Ethernet network.

9.1 Using the SLEM-1 Expansion Module

For systems with up to 4 fi xtures, where 24 VDC output is the

desired interface to the machine control, the SLEM-1 Expansion

Module (optional accessory) provides additional expansion

capabilities. The SLEM-1 allows up to two additional SLS send

units to be added to the SafeLink system.

The output terminal block of the SLEM-1 is the same as

that used on the SLR receive unit. See Figure 6 for wiring

instructions.

9.2 Setting up a Modbus Based System

For machine controls that use Modbus RTU or TCP protocols,

the SLR-1 and SLR-2 receive units provide a built in Modbus

system.

The Modbus Serial Line RTU protocol is a master-slave protocol

typically used for industrial applications. It is an open standard

implementation of Modbus based on Internet protocols.

Modbus TCP/IP is similar to Modbus RTU but transmits

information within TCP/IP data packets.

8