Enerpac ECM-Series User Manual

Page 4

4

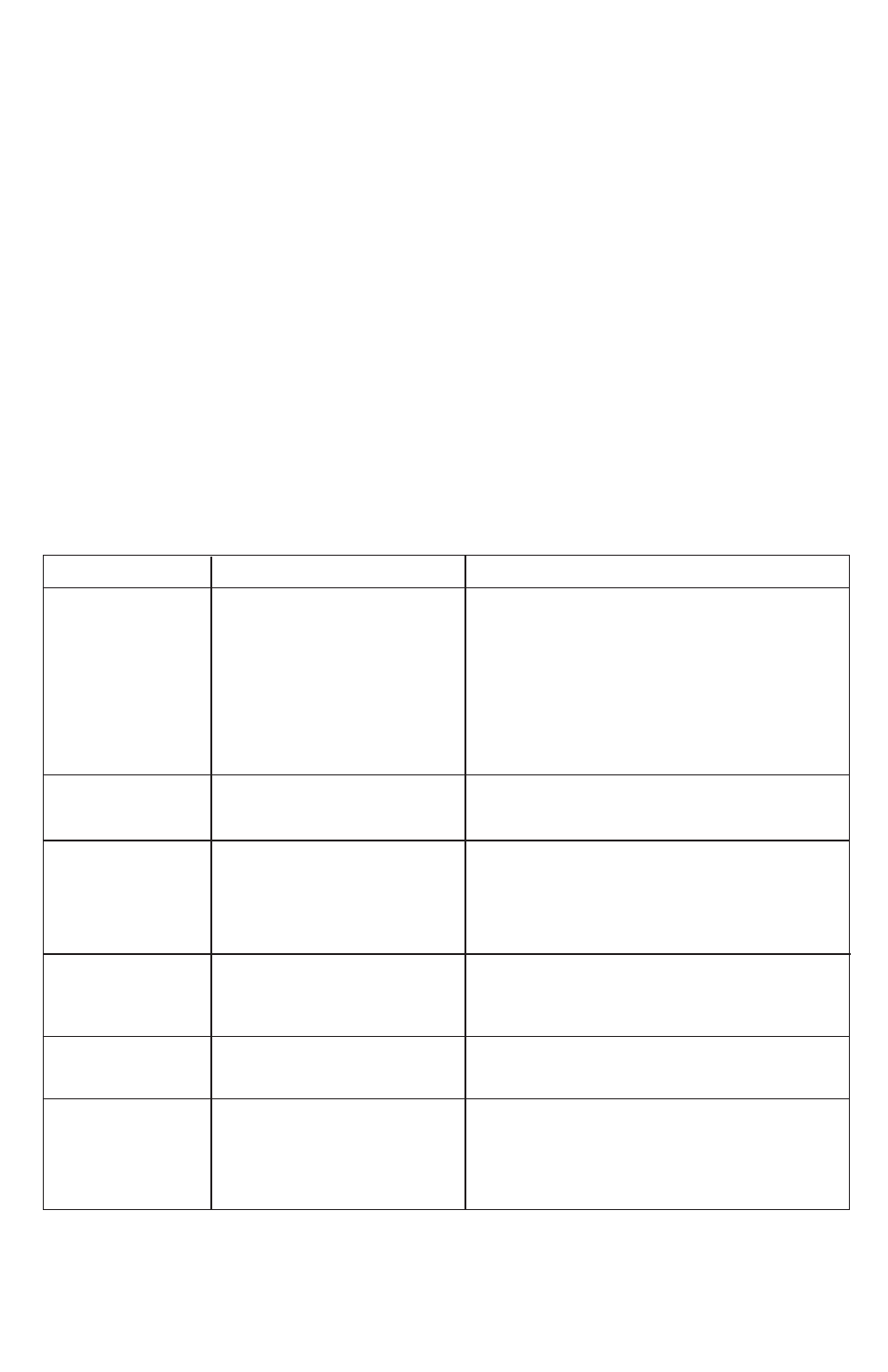

PROBLEM

Clamp does not

advance/retract.

Clamp advances

part way only.

Clamp advances/

retracts slower

than normal.

Clamp advances /

retracts but does

not hold pressure.

Clamp leaks oil.

No Pull-down

effect

SOLUTION

1. Check control.

2. Fill reservoir with Enerpac Hydraulic Fluid.

3. Remove air from hydraulic system.

4. Tighten all couplers.

5. Check valves, fittings, and tubes.

6. Replace with Enerpac spring.

1. Fill Reservoir with Enerpac hydraulic oil.

2. Remove air from hydraulic system.

1. Connections, couplers, and tubes must be

mounted again.

2. Check valves, fittings, and tubes.

3. Perform maintenance on pump.

1. Replace with Enerpac seals.

2. Check valves, fittings, and tubes.

3. Perform maintenance on pump.

1. Broken parts must be replaced.

2. Replace with Enerpac Seals

1. Clean rubber spring area and repair slide

surfaces. See Maintenance section above.

2. Clean rubber spring area and repair slide

surfaces. See Maintenance section above.

POSSIBLE CAUSE

1. Valve is not switched

correctly

2. Oil level in the reservoir

is too low.

3. Air trapped in system.

4. Loose coupler.

5. No pressure is built up.

6. Cylinder spring is broken.

1. Oil level is too low.

2. Air trapped in system.

1. Leaking connection.

2. Reduced Hydraulic circuit.

3. Malfunction of the pump.

1. Defective seals.

2. Leaking connections.

3. Malfunction of the pump.

1. Defective piston.

2. Defective seals.

1. Contaminated rubber

spring area.

2. Damaged slide surfaces.

TROUBLESHOOTING

5.0 OPERATION

Loading parts on the upper “1/8” of an inch of

jaw only, may result in substantially reduced

service life.

6.0 MAINTENANCE / REPLACING

CLAMPING JAWS

1. Loosen the retaining bolt at the front of the

clamp or the counter-hold and remove it.

2. Take out the clamping jaw.

3. Clean the rubber spring area. If necessary,

tighten the rubber spring with a pipe wrench.

4. Check the slide surfaces of the clamping jaw

and the clamping bolt and repair any damage.

5. Fasten the clamping jaws with screws.

6. Replace mounting bolt and tighten securely.