Theory of operation, The rfd oven series, Danger – Despatch RFD Series User Manual

Page 16

T

HEORY OF

O

PERATION

RFD Oven Series

Owner’s Manual

16

Version 1

Copyright © 2012 by Despatch Industries.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

3.

Theory of Operation

3.1. The RFD Oven Series

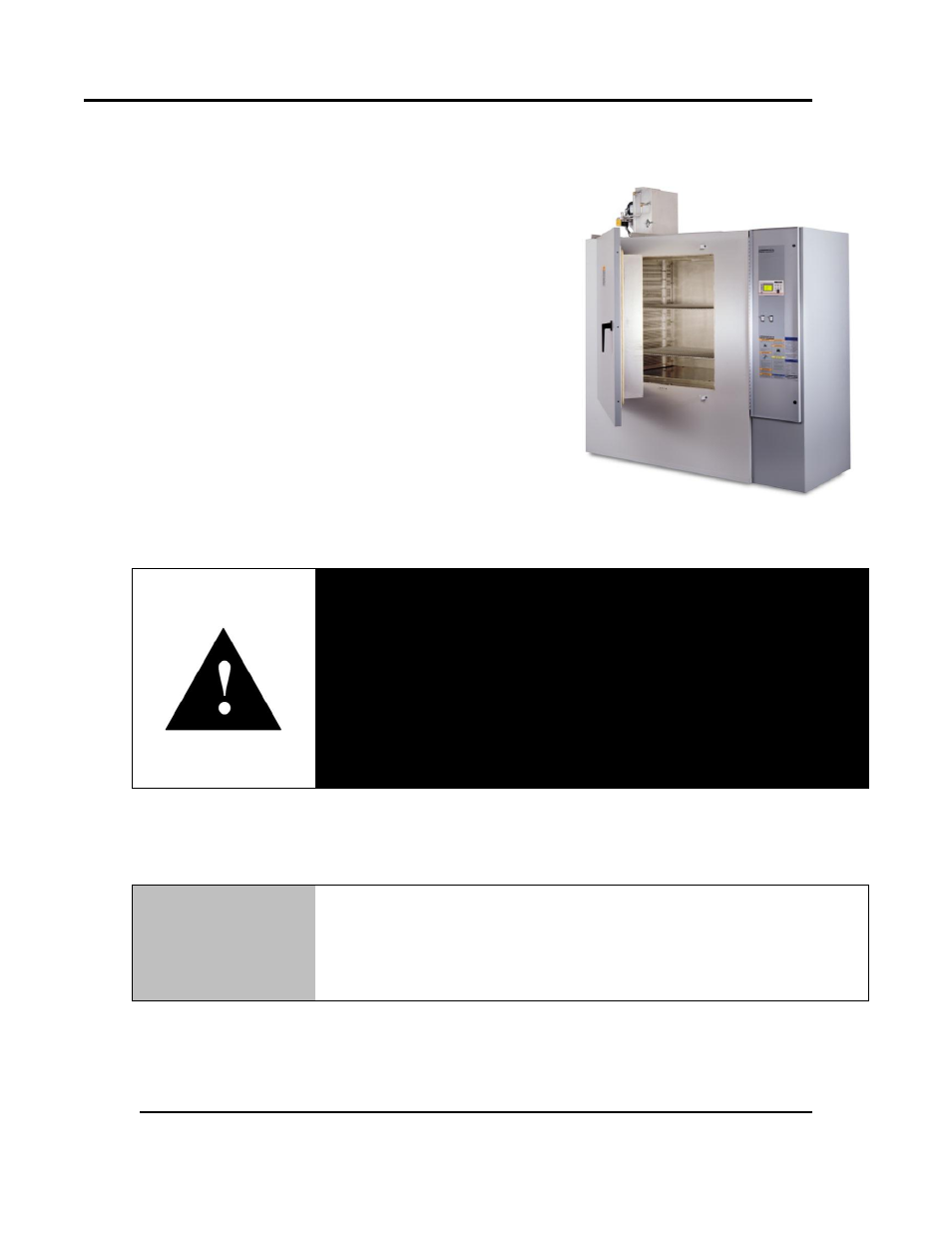

Despatch RFD ovens feature horizontal recirculating airflow

to ensure exceptional temperature uniformity throughout the

oven. A high-volume fan circulates air through perforated,

stainless steel walls to create a constant horizontal airflow

across all sections of the oven. The result is proven

reliability in demanding production and laboratory

applications, such as curing, drying, sterilizing, aging, and

other process-critical applications.

The RFD ovens are for applications that include flammable

solvents or large amounts of moisture removal. These Class

A ovens are specially designed to meet NFPA 86

requirements. They include a pressure relief panel, purge

timer and exhaust fan.

Danger!

Class A ovens are designed for a specific amount of solvent. Exceeding

this amount could result in an explosion. Refer to Design Specification

Label (Figure 14) or Section 1.5.2 for the solvent handling capabilities of

this oven. Do not process closed containers of any substance or liquid

in this oven because they may explode under heat. In case of fire, leave

door(s) as they are. Shut off electricity. Shut off fuel. Call the fire

department. Stay away

.

Notice

With the damper in full closed position, a predetermined amount of

fresh air enters the chamber via cutaways in the fresh air and exhaust

dampers. This amount of fresh air meets NFPA86 Safety Guidelines for

Class A ovens.

Figure 4. RFD Oven Series.