2 probe – menu, 3 cal – menu – Dakota Ultrasonics CMX DL plus User Manual

Page 30

Dakota Ultrasonics

26

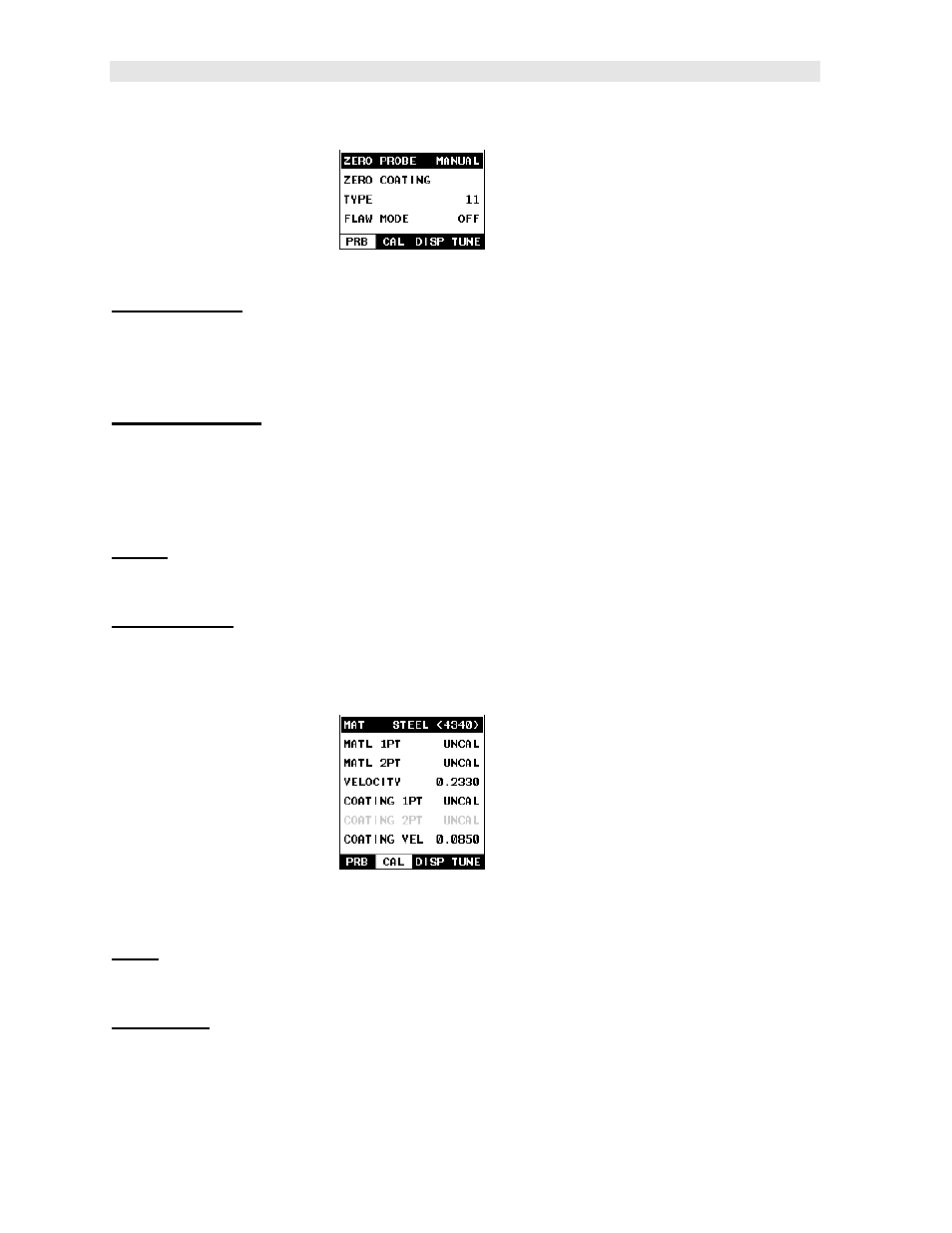

3.2 Probe – Menu

ZERO PROBE: The CMX

DL+

is zeroed in much the same way that a mechanical

micrometer is zeroed. If the CMX

DL+

is not zeroed correctly, all of the measurements

made using the CMX

DL+

may be in error by some fixed value. The CMX

DL+

is

equipped with an optional auto matic or manual zero feature. Refer to the section on

page 48, for an explanation of this important procedure.

ZERO COATING: In order to account for very slight electronic differences in

transducers of the same type, frequency, and diameter, the CMX

DL+

has been

equipped with a “zero coating” feature. This enables the CMX

DL+

to obtain very

accurate readings on coatings, eliminating potential errors incurred from slight

differences in the manufacturing processes. Refer to the section on page 48, for a

detailed explanation.

TYPE: Enables the user to select the type of transducer being used from a chart of

transducer types. This provides increased linearity between transducers. Refer to

page 44 for a further explanation.

FLAW MODE: Activates the flaw detection mode and view. This feature is for use

with single element angle beam transducers and used as a general prove-up flaw

inspection mode. Refer to page 120 for a further explanation.

3.3 CAL – Menu

MAT: Select the material velocity from a chart of basic material types when a known

sample thickness, or material velocity cannot be obtained. Refer to page 57 for

further info.

MATL 1PT: Performs a single point calibration. This option allows the user to

automatically calculate the velocity by entering a known sample thickness. Refer to

page 54 for further info.