Set up the puller – Condux CableGlider FO Cable Puller User Manual

Page 7

7

Set up the Puller

This manual contains setup and operating instructions for the Condux Fiber Optic Cable Puller with electronic

control box, if equipped. Where operations differ for the other available packages, the instructions specify

those differences.

A. mOUNT THE PULLER

1. The Fiber Optic Cable Puller has a 2

1

⁄

2

x 2

1

⁄

2

inch (64 x 64 mm) square mounting post. A female receiver,

such as the receivers listed in appendix 13.F and 13.G, is

recommended. Use grade 5 or grade 8 capscrews to attach these mounts. Materials used for constructing

your own mount should have a minimum wall thickness of

1

⁄

4

inch (6.25 mm). All welds should be continuous, and gussets should be used

where possible.

!CAUTION: Lift the Fiber Optic Cable Puller only with proper equipment or

sufficient manpower. Improper lifting techniques may result in personal injury

or property damage.

b. CONNECT THE HYDRAULIC SYSTEmS

The Fiber Optic Cable Puller’s hydraulic system uses quick-connect couplings. Keep all connections clean to

avoid contamination and possible system failure. Follow these steps to connect the hydraulic components:

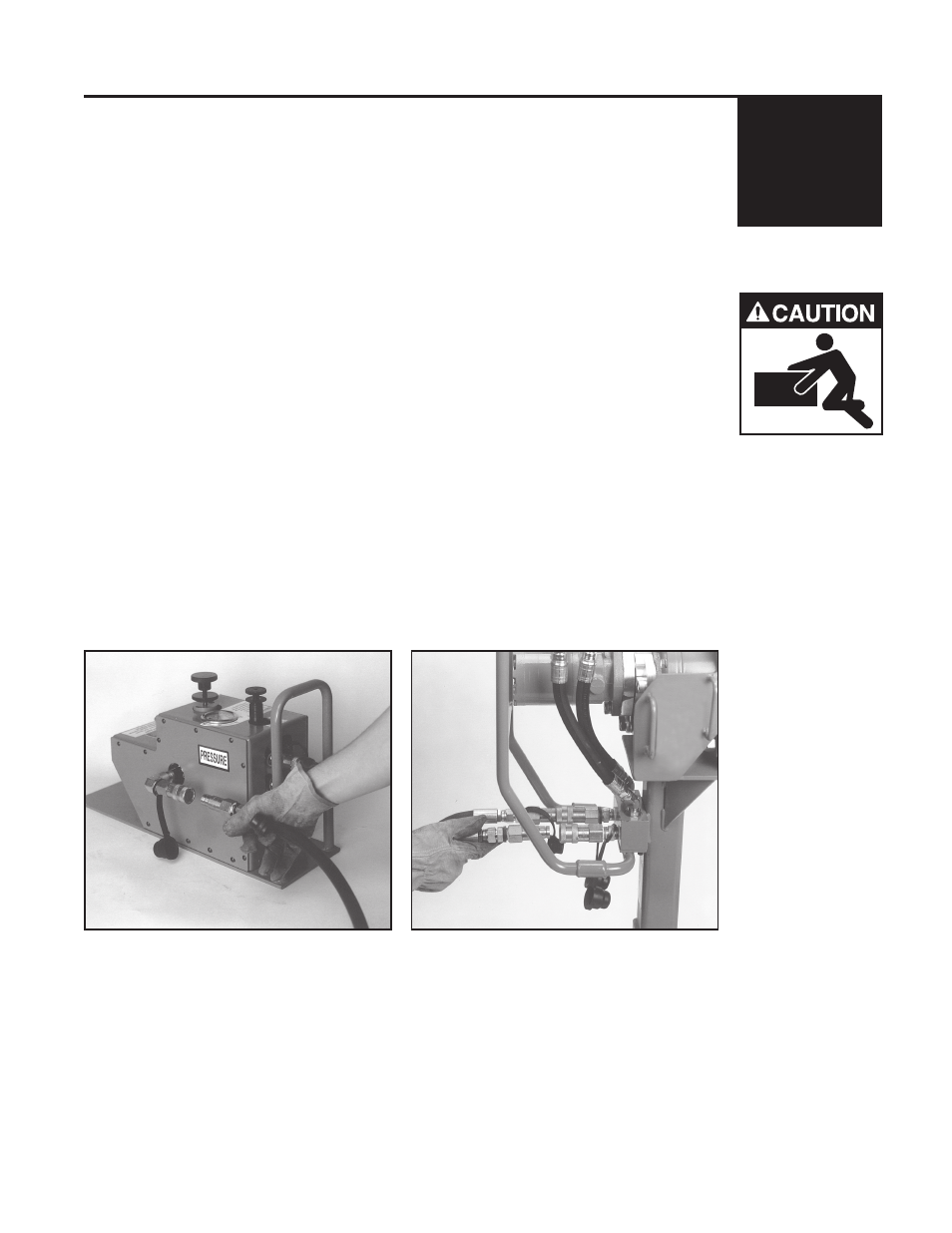

1. Connect the hydraulic supply hoses to the foot control valve assembly. Ensure the pressure hose

from the power source goes to the inlet of the foot control valve (labeled PRESSURE

on the foot control valve assembly, figure 1).

2. Connect the hoses from the foot control valve assembly to the puller (figure 2). The

supply hose assembly has four identical male couplings and can be attached between the puller and foot

control valve assembly in any orientation.

!NOTE: Switching the quick-connect couplings on one end of hose assembly

between the puller and the foot control valve assembly will reverse the direction of

capstan rotation.

3. Start the hydraulic power source and check all connections for leaks with a piece of cardboard. Run the

puller in both directions to ensure proper operation.

5.

Figure 1. Power Supply Connections

Figure 2. Foot Control Connections