Condux CableGlider FO Cable Puller User Manual

Page 11

11

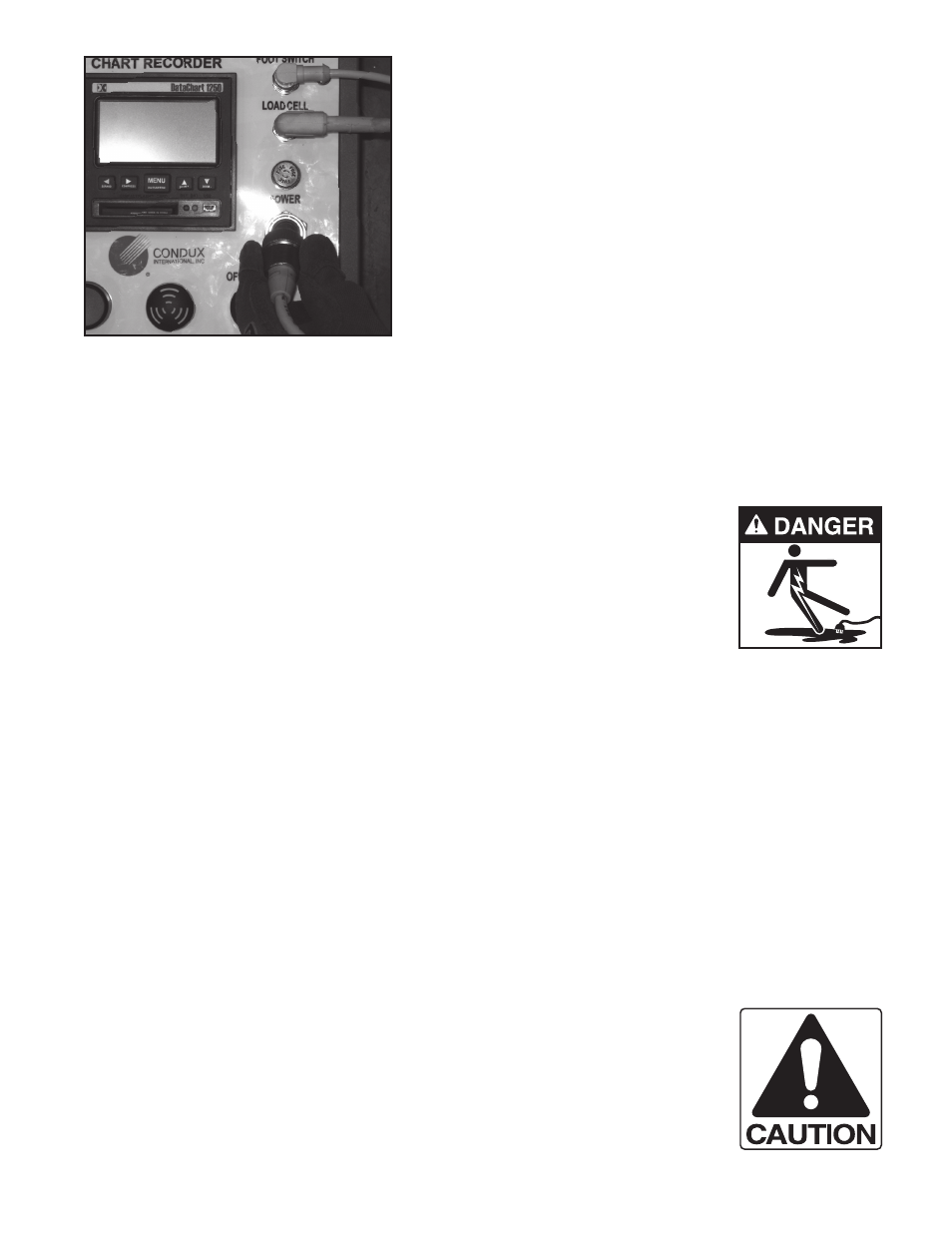

3. The 7/8” 2-pin connector on the front panel of the

electronic control box supplies electrical power to

the electronic control box. (see Figure 10) This

power can come from the power pack, a vehicles

power point, or a lighter socket. The electronic

control box requires 12 Volt DC power for proper

operation.

4. Connect the power cord to the 2-pin connector

labeled “POWER”. Before making these connec-

tions, ensure the receptacle is free of dirt and

moisture. Tighten the connector collar over the

threaded portion of the receptacle. This will pre-

vent the cord from coming loose during opera-

tion. Connect the other end of the power cord to

a 12 Volt DC power source.

C. SETTINg UP THE ELECTRONIC CONTROL bOX

The Condux Fiber Optic Tensiometer has been designed to give the operator continuous tension informa-

tion and automatic shut-off control during a pull. The Electronic Control Box features an LED Display,

Digital Graph Display, 256MB Flash Card, and a 3 capstan selection switch. A programmable overload set

point with both visual and audible alarms is designed to disengage the cable puller should an overload

occur. Navigator software is provided so pulling information can be downloaded onto any computer running

Windows 2000® or XP®.

!DANgER: The main Power switch supplies power to the indicator and chart

recorder. When a power supply is connected to the electronic control box, portions

of it are energized. Follow all electrical equipment precautions.

!NOTE: Always disconnect the power cord when the electronic control box is not in use. When the power

cord is connected to the electronic control box, it energizes portions of the control box. If the power cord is left

attached when the control box is not in use, it will drain the power supply.

1. Turn the power switch on the Electronic Control Box to the “ON” position (See Figure 5). Be sure that the

sensor cords are properly connected before turning on power.

2. Select the capstan size. Turn the capstan selection switch so the appropriate channel is lit on the

Meter. In order to get accurate results, the correct capstan size must be selected. The electronic control box

is programmed to accurately return pull tension for Condux 12”, 30”, and 42” fiber optic capstans.

3. Set the cable Tension Limit. Press the “Prog” Button and ▼ button simultaneously. (See Figure 5)

SP-1 will appear on the on the LED Screen. The screen will alternate between SP-1 and the current ten-

sion limit. Press the ▲ and▼ buttons to increase or decrease the tension limit. Once the desired tension

limit is set, press “Prog” to save the set point.

4. Zero the display. Press the “Prog” button.

5. Alarms: When Tension Limiter switch is in the “OFF” position the audio alarm will sound and the light

will come on when the tension limit is reached. When the Tension Limiter switch is in the “ON” position the

puller will also stop pulling when the tension limit is reached (See Figure 5)

!CAUTION: Damage to cable may result from excessive pulling forces. Use

precautions to safeguard against overload conditions.

D. DIgITAL CHART RECORDER SET UP

The Digital Chart Recorder is the next generation Solid State Data Recorder/Panel Recorder. This instru-

ment has all the capability of a traditional paper recorder – variable chart speeds, the ability to review his-

toric data, see trends and more. All pull data is stored on the 256MB Compact Flash Card that comes with

the unit.

1. Name File Press “MENU” button to enter the Menu screen. Use ▲ and ▼ arrows to scroll to RECORD

MODE and press menu. Next, scroll to “NAME FILE” and press MENU. Use the ▲ and ▼ buttons to

Figure 10. ECb Power Connection