Caution, Automobile performance, custom and aluminum wheels – COATS RC-100 Tire Changer User Manual

Page 16

12 •

Important: Always read and follow operating instructions.

Automobile Performance, Custom

and Aluminum Wheels

CAUTION

Only tire technicians with experience and

training on custom wheels should attempt

to service expensive custom alloy or alu-

minum wheels and high-performance low-

profile tires.

Pre-Operation Notes:

• Ensure all weights have been removed.

• Assistance will be required on wide wheels.

• Clamp wheel from the outside.

• Use ample lubricant for mount and demounting

•

Always review wheel nicks and/or scratches

with the owner before servicing.

Aluminum and Custom Wheels

Follow instructions provided for standard steel wheels,

except:

A. After loosening and lubricating both beads, rotate

the table top until the clamps are in the 12, 3, 6, and

9 o’clock positions.

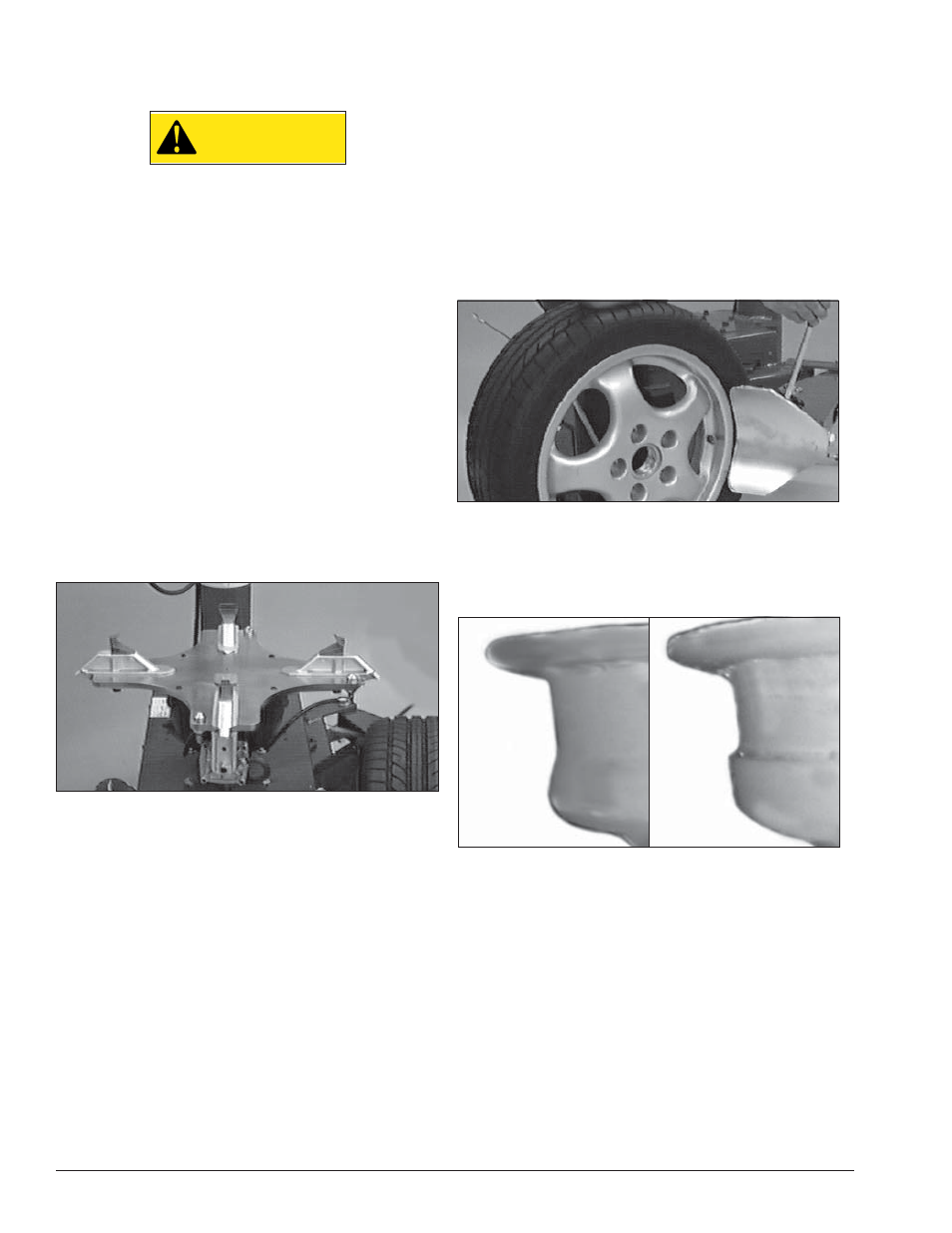

Figure 17 - Rotate Table Top to 12 O’clock

B. Clamp wheel from the outside. Position rim edge

into clamp at 12 o’clock position. Lower the wheel

and depress the clamp control pedal. Slowly move

the clamps inward until they securely contact the

outside edge of the rim.

TIP: This is usually accomplished by crouching down

in front of the tire changer, holding the wheel with the

right hand, and operating the clamp control pedal with

the left hand. This allows the operator to watch the

clamps as they move to ensure proper, damage-free

clamping.

Performance Tires and Wheels • Demounting

Follow these instructions for performance type tires

and wheels, including run-flat tires and their associated

wheels, and asymmetrical hump wheels.

1.

Remove the valve core and completely deflate the

tire.

2.

Pull the bead loosener shoe away from the machine

and roll the tire into position against the bumper pad.

Position the tire with the valve stem in the 3 o’clock

position (in direct line with the bead loosener shoe).

Always loosen the bead on the narrow/mounting side

of the wheel first (Figures 4 and 18).

Figure 18 - Position Tire for Bead Loosening

NOTE: Wheels with an asymmetrical hump have a

larger “ledge” type hump around the wheel except at

the valve hole making them more difficult to mount and

demount (Figure 19).

Figure 19 - Asymmetrical Hump Wheel

Smooth

Hump

At Valve

Hole

Ledge

Hump -

Rest of

Wheel