Mounting–valve-type sensor – COATS Extended Mobility (EMT) RunFlat Tires User Manual

Page 22

G–2

Mounting–Valve-Type Sensor

6

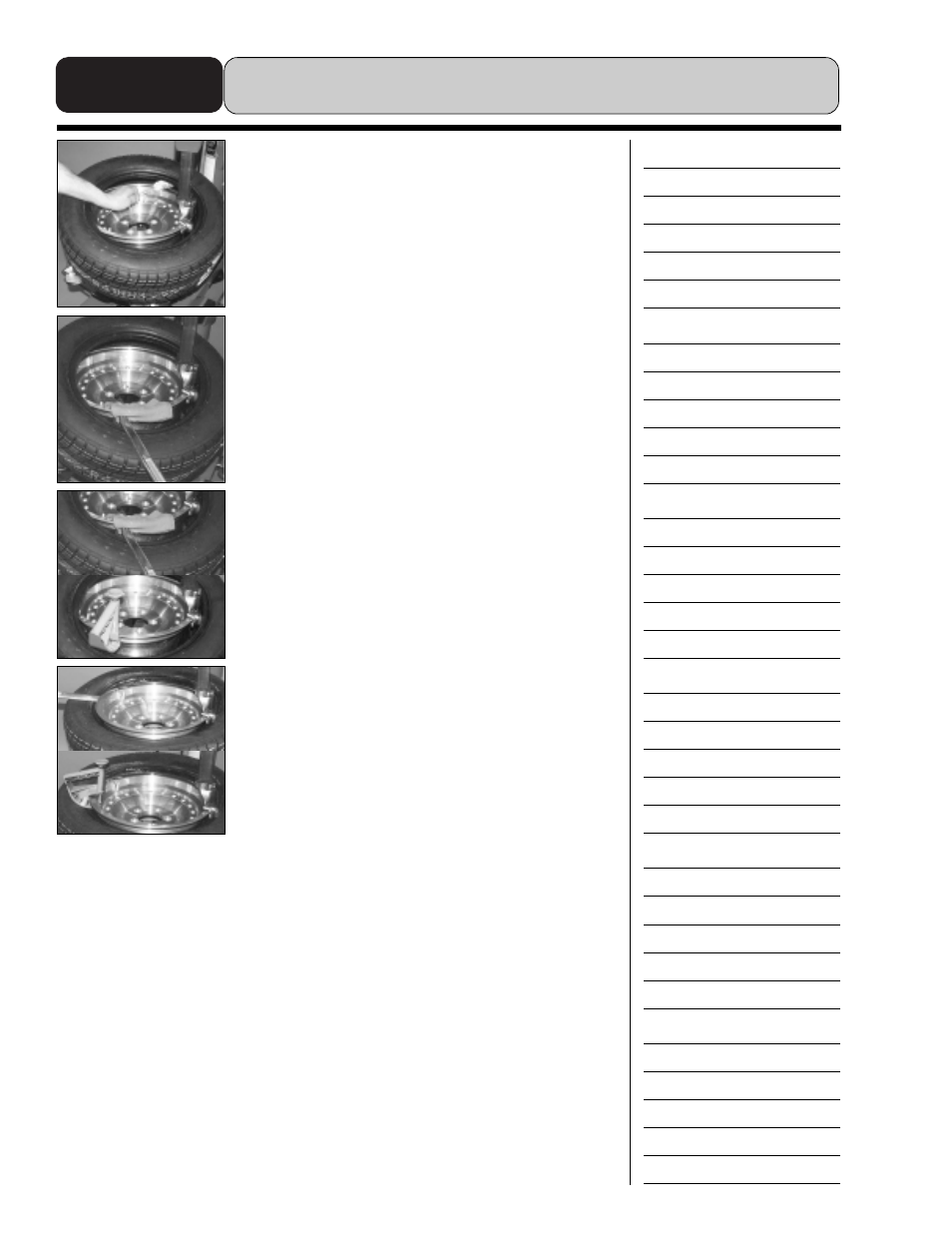

Once the lower bead is mounted, rotate the table top

until the valve stem and pressure sensor are once again

in the 6 o’clock position.

Lubricate the upper bead liberally. Apply lubricant to both the

edge of the tire bead and the underside of the bead.

Adequate lubrication is vital to the upper bead mounting

process.

7

Position the upper bead over the duckhead. Put the tip of

the lift tool under the wheel rim flange and push the bar

down to hold the upper bead below the wheel and duckhead.

Use a shop towel on the lift tool to avoid damaging the wheel.

8

Rotate the wheel a short distance–only 3 to 4 inch-

es–and stop. Continue to hold the bead in the drop cen-

ter with the lift bar, or place a drop center tool on the wheel.

Remember that stiff sidewall tires are difficult to mount. The

top bead is always more difficult to work with because the

tire cannot be angled across the drop center and rim flange

as easily as the lower bead.

9

Continue rotating the wheel, moving only a few inches

and then stopping.

Continue to hold the bead in the drop center with the lift bar

or the drop center tool. When the bar or the drop center tool

reach the 10 o’clock position, remove them. Continuing with

either tool in place may cause them to be forcefully ejected

from the wheel.

Continue rotating the wheel until the upper bead is fully mounted.

This completes Section G.