COATS 9010 AX/EX Tire Changer User Manual

Page 6

5.

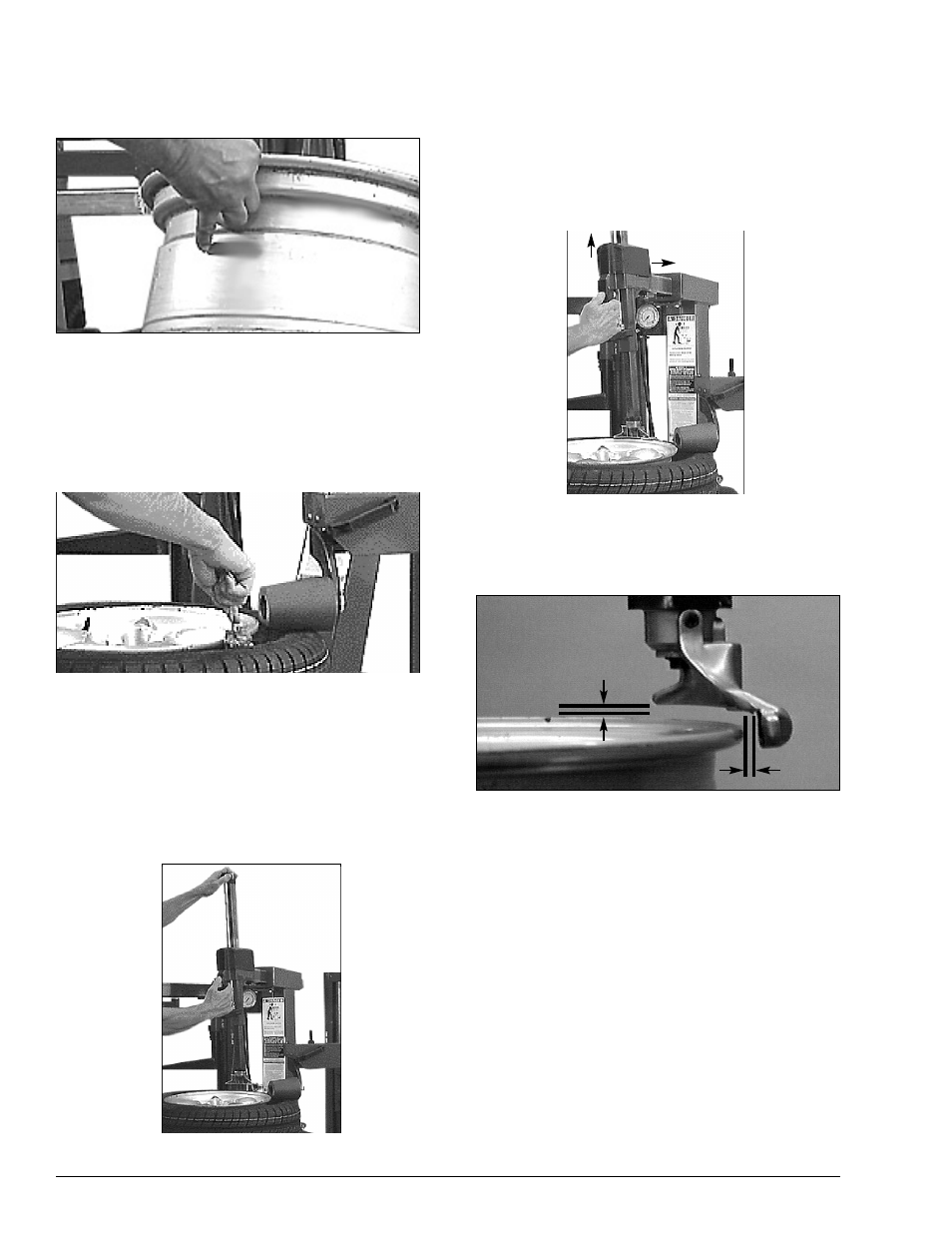

Place tire/wheel assembly on table top with

mounting side up (Figure 4). Use the clamp

control pedal to move the clamps inwards (push

pedal down) or outwards (toggle pedal up).

Figure 4 – Place Tire/Wheel Assembly on Table Top

Clamp

steel wheels from the inside (clamps push

outwards against wheel). Clamp mag and

custom wheels from outside (Clamps push

inwards against the outside rim edge). Refer to

the Performance Tires and Wheels section.

Figure 5 - Apply Rubber lubricant to the beads

6.

Apply tire manufacturer’s approved rubber

lubricant liberally to entire circumference of both

beads after loosening and placing on table top.

Using L.H. & R.H. helpers to hold down top

bead while rotating wheel and lower lift disk for

bottom bead will make lubrication easier (Figure

5).

Figure 6 - Position Mount/Demount Tool

7. Move the tower forward into position. Pull the

locking valve button forward to release the slides.

The vertical slide will descend. Pull the slide handle

to move the demount head into contact with the rim

edge. Push the locking valve button to lock the

slides into place. As the slides are locked, the

mount/demount head will move upward

approximately 1/8 inch and backward 1/8 inch from

the rim edge. (Figures 6 & 7)

Figure 7 - Adjust Slides to Position Head Roller

8.

The mount/demount head roller should not be in

contact with the rim edge & the flat area under the

head should be raised above rim flange (figure 7).

Figure 8 - Proper Mount/Demount Head Postion

9.

Check head positioning. Mount/demount head

should be positioned with 1/8 to 3/16" clearance

between the top of the rim edge and the bottom

of the head, and 1/8 to 1/4 inch clearance

between the rim edge and the head roller. This

clearance will be maintained as long as the slide

locking valve remains locked. The operator may

move the tower back out of the way and back

into place again without needing to reposition

the head (when changing a like set of wheels)

(Figure 8).

H. The tool clearance may change with machine

use and should be inspected often. Failure to

maintain the proper clearance may result in

damage to the wheel rim and/or tire.

4 • 9010 Rim Clamp Tire Changer

1/8" to 1/4"

1/8" to 3/16"