Danger – COATS 9010 AX/EX Tire Changer User Manual

Page 17

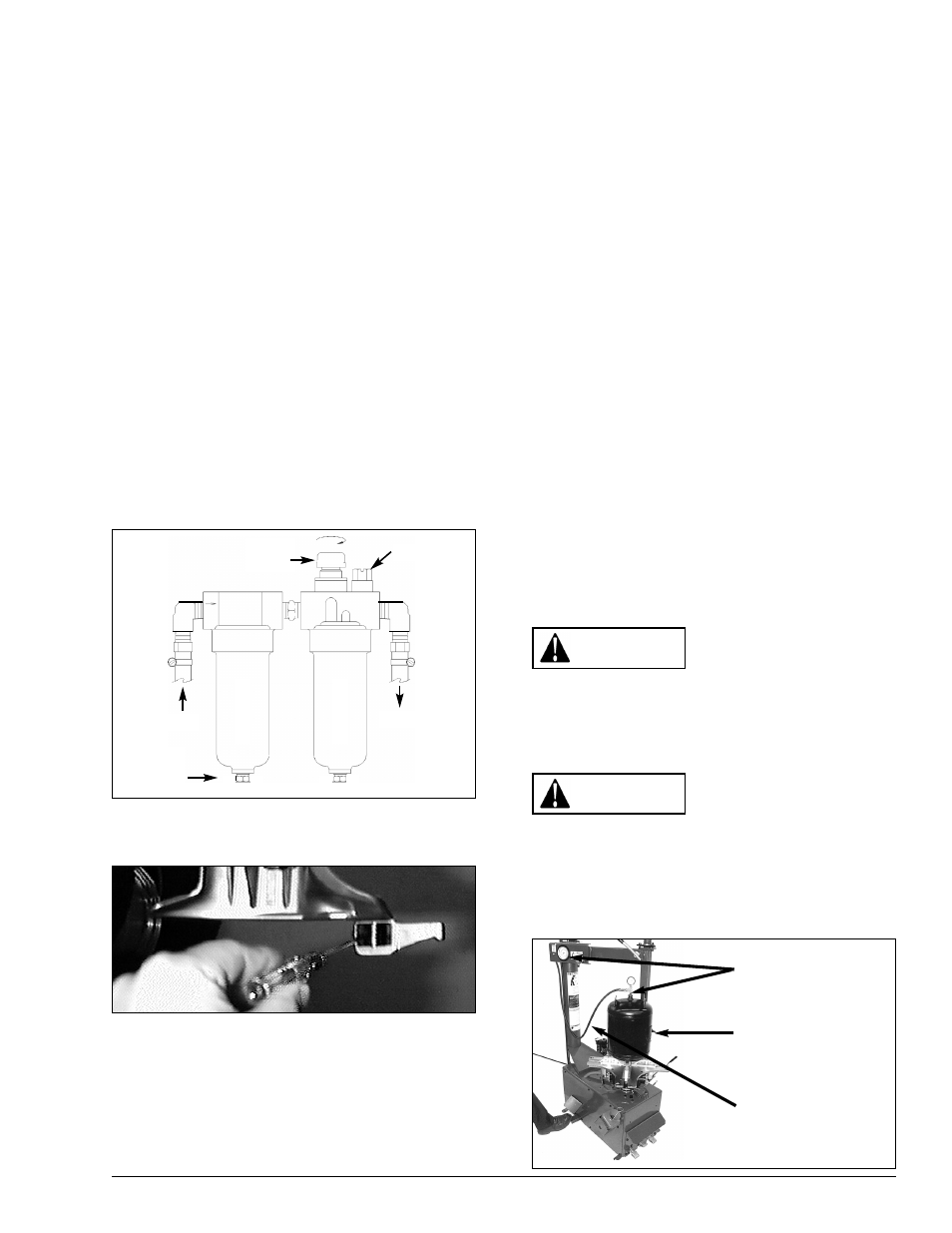

Separator/Lubricator Maintenance

Check oil and water levels regularly, and perform

these maintenance items weekly:

A. Disconnect air supply to machine.

B. The Separator (Filter) unit is equiped with an

automatic drain and should not normally need

draining.

C. Add oil to the lubricator if the fluid level is more

than 1/4” from the top of the gauge. Remove the

filler plug on top of the lubricator and add SAE

10W non-detergent oil or an air tool oil to bring

the level up to 1/4” from the top of the gauge.

Replace filler plug and clean up any spilled oil.

D. Adjust the oil flow by turning the black flow

adjustment knob and turning it to increase or

decrease the flow. Watch the formation of oil

drops in the see-through oil chamber.

Reconnect the air supply and continually cycle

the bead loosener through full strokes and count

the drips during the cycles. The delivery of oil to

the air line should be about 1 drop per 10

cylinder cycles. Adjust flow as required.

Mount/Demount Head Cleaning

Clean dirt and debris from the mount/demount tool

(duckhead) roller with small screw driver or pick.

Pressure Limiter Maintenance

The pressure limiter helps prevent inflation of

standard size or larger tires or tubes beyond 60 PSI

to minimize risk of explosion. This device is for the

safety of the operator and bystanders. Proper

operation of the pressure limiter is essential to safe

operation of the machine.

Check operation of the pressure limiter as shown

and described below at least monthly:

1.

Remove tires and/or wheels from the machine.

2.

Connect the inflation hose to an empty service

tank with a pressure gauge (gauge should read

0). Use a certified tank with at least 250 PSI

pressure rating.

3.

Depress inflation pedal to position 1 to start air

flow through the hose and into the tank.

Maintain a steady pressure for constant flow.

4.

Watch the rising pressure on the tank gauge

and the gauge on the machine. Machine gauge

should cycle between check and inflation

pressures while tank gauge climbs steadily. As

tank pressure reaches 60 PSI, the pressure

limiter should stop the air flow automatically.

Both gauges should read 60 PSI ± 5 PSI.

5.

Release inflation pedal. Check manual release

valve function by pressing the button and

releasing pressure from the tank until it reaches

50 PSI. Disconnect inflation hose, and release

air inside tank.

6.

Replace pressure limiter if it fails to cycle

properly during inflation, if it fails to shut air

supply off at 60 PSI, or if it malfunctions in any

other way. Do not operate machine with a faulty

pressure limiter.

Operating a tire changer

with a defective,

improperly adjusted, or

by-passed pressure

limiter could result in a tire explosion with

severe injury or death to the operator or

bystanders. Always be sure that the pressure

limiter is present and is operating properly on

the machine at all times.

Never inflate tire above

m a n u f a c t u r e r ’ s

recommended pressure

after bead is seated.

Pressure limiter is set at 60 PSI. Any required

inflation above 60 PSI should be performed in an

inflation chamber/safety cage or securely

mounted on the vehicle if an inflation chamber is

not available. A tire explosion may cause

personal injury or death to operator or

bystanders.

9010 Rim Clamp Tire Changer • 15

Auto

Drain

Outlet

Air In

Air Out

Oil Fill

Oil Flow

Adjust

Lubricator

Separator

250 PSI Tank

with Gauge

Watch Pressure

on Both Gauges

Tire Changer

Inflation Hose

Connected to Tank

DANGER

DANGER