Caution, Warning – COATS HIT 6000 Truck Tire Changer User Manual

Page 8

6 • COATS Heavy Duty Tire Changer

WARNING

Allowing both shoes or one shoe and the

rim stop to contact the rim during bead loos-

ening may cause rim damage.

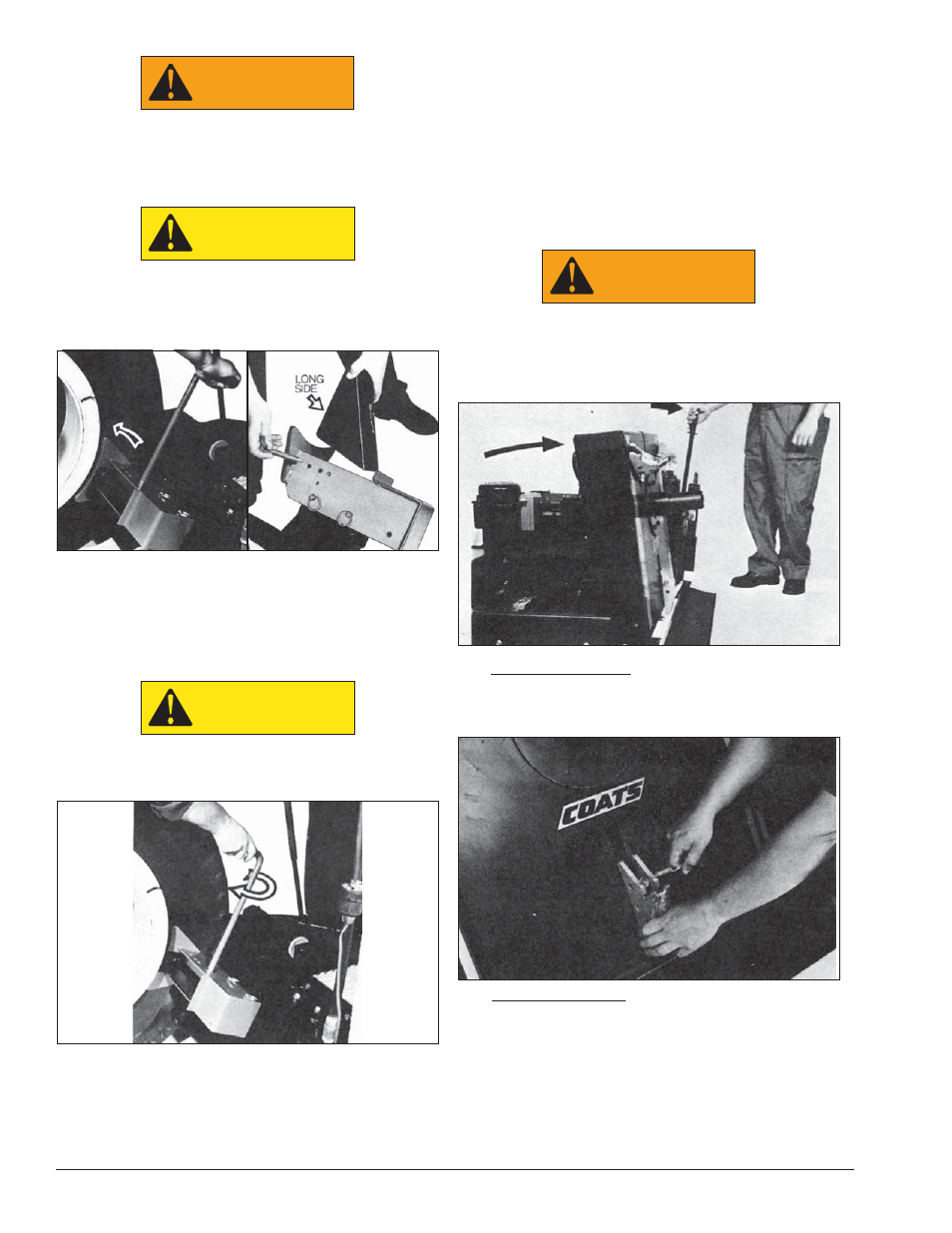

Multiple Piece Rim Bead Loosening

CAUTION

Before attempting to loosen beads, remove

the valve core and be sure the tire is com-

pletely deflated. Do not place any part of the

body between bead loosener shoes.

1.

Place rim stop in tube type tire position; see illus-

tration.

2.

Position tire between bead loosener shoes with

the ring(s) toward the kicker shoe.

Position bead loosener shoe with 1/4" of lock ring.

CAUTION

Do not let shoes push on rim or lock ring(s).

Rim or rings may become warped and dam-

aged.

3.

Actuate bead loosener so that the bead loosener

shoe pushes bead in. As the kicker shoe passes the

ring, pull handle to bring the kicker shoe up to the bead.

Continue to full stroke of bead loosener.

4.

Disengage bead loosener shoes and turn tire 90

degrees and repeat steps 1, 2, & 3 until bead is loos-

ened.

5.

Use bead loosener shoes to hold tire and remove

lock ring.

6.

To loosen other bead, remove wheel assembly

from between the shoes and pivot tire 180 degrees

to position the ring side of the wheel near rim stop.

Repeat steps 2, 3, and 4 above.

WARNING

Always inflate tires inside a safety infla-

tion cage. Tire explosion during inflation can

cause serious injury or death.

Clamping

1.

Raise working table: Raise working table to almost

vertical position by pulling back on the control handle.

Open clamps by twisting the control handle counter-

clockwise.

2.

Clamp Adjustment: Adjust all three clamps to the

proper wheel diameter range. The front hole position

is for 19.5" to 24.5". The rear hole position is for 16" to

19.5".