COATS HIT 6000 Truck Tire Changer User Manual

Page 12

10 • COATS Heavy Duty Tire Changer

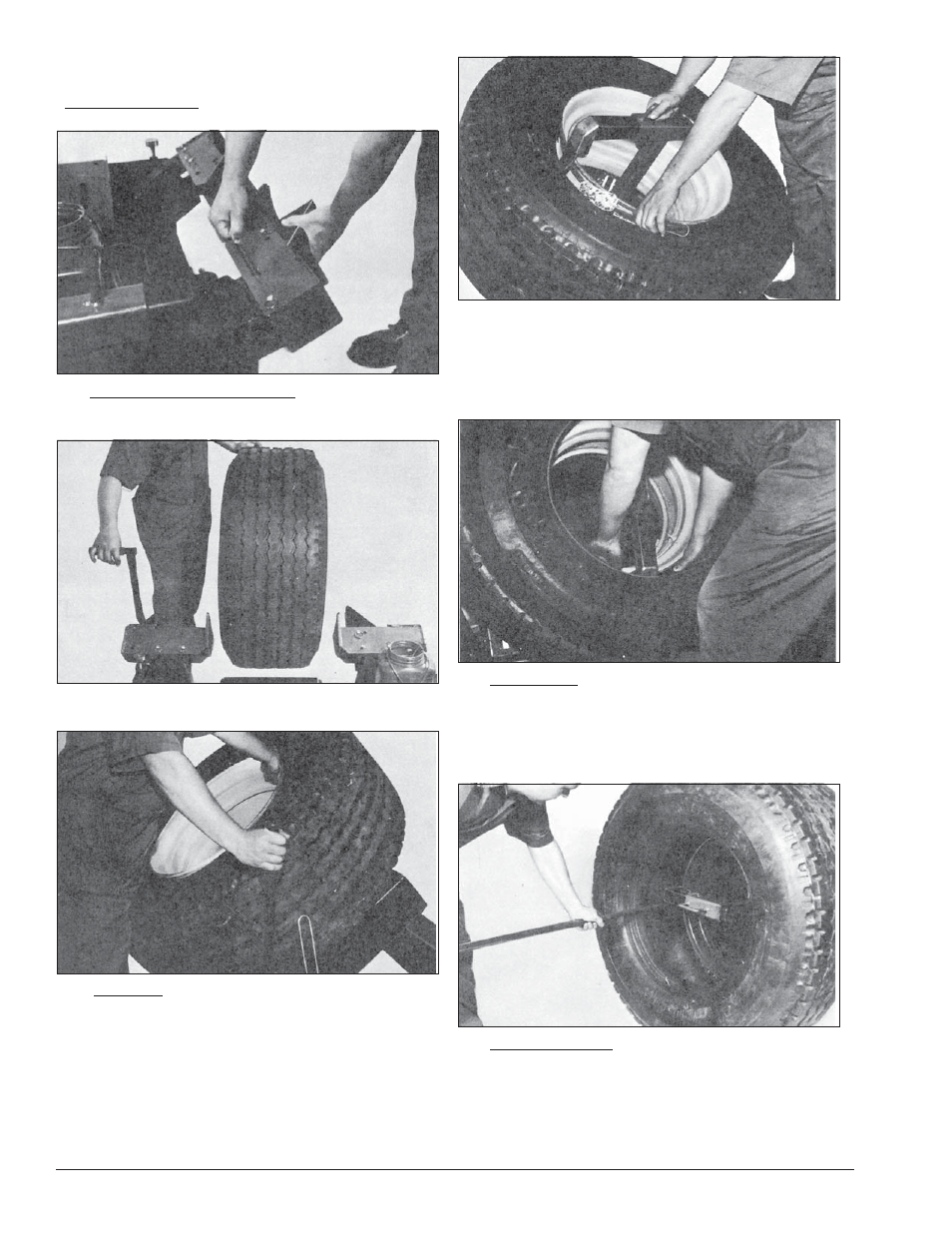

Special Instructions for “Duplex” or “Super

Single” Tires

Wheel Preparation: Remove valve core and allow tire

to deflate completely. Remove all wheel weights.

1.

Adjust Bead Loosener Shoes: For tire width of 10"

and over, one or both bead loosening shoes should be

adjusted.

2.

Position tire and loosen beads as explained in the

bead loosening section.

3.

Clamping: Due to the stiff sidewall, it may be

necessary to push down on the rim at the top as the

clamps are being closed, to engage the rim. Lowering

the table slightly will let the wheel’s weight help in

clamping.

4.

Lubricate tire beads and rim flange thoroughly: It

may be easier to lubricate the top bead by letting the

mount/demount tool push down on the bead and then

rotating the tool with the lube swab following the tool.

Demount the top bead in the usual manner). See sec-

tion one.

5.

Position Tire: It will be necessary to get the bottom

bead into drop center by raising the working table to

almost vertical (do not allow the tire to touch floor). Pull

out on tire as shown until bottom bead moves into drop

center. Then raise working table until tire rests on floor

to hold it in drop center.

6.

Insert Bead Lifter: With bottom bead in drop center

and tire resting on the floor, rotate tool to 9 o’clock posi-

tion and insert bead lifter under bottom bead just below

the tool head.