Caution, Installation – COATS 575 Heavy Duty Tire Lift User Manual

Page 6

6 • COATS Heavy Duty Tire Lift

Installation

Pneumatic Connection

Connect air intake to a compressed air system with

a working pressure of 120-150 PSI. Use a compressed

air hose with an inside diameter of 1/4” - 3/8”.

CAUTION

Make sure air hose is free of the BASE

TRACK area. If the air hose is damaged, the

Tire Lift may descend unexpectedly.

Assembly Instructions

Tools Required:

• F (0.257") or G (0.261") Size Drill Bit

• Center Punch

• Marker

• 9/16-inch Socket

• Ratchet

• 9/16-inch Combination Wrench

• Ruler

575 Heavy Duty Tire Lift Components:

• STORAGE BRACKET

• TOWER ASSEMBLY

• WHEEL TRAY

• BASE TRACK (with CARRIAGE INSERT)

• FASTENERS

1.

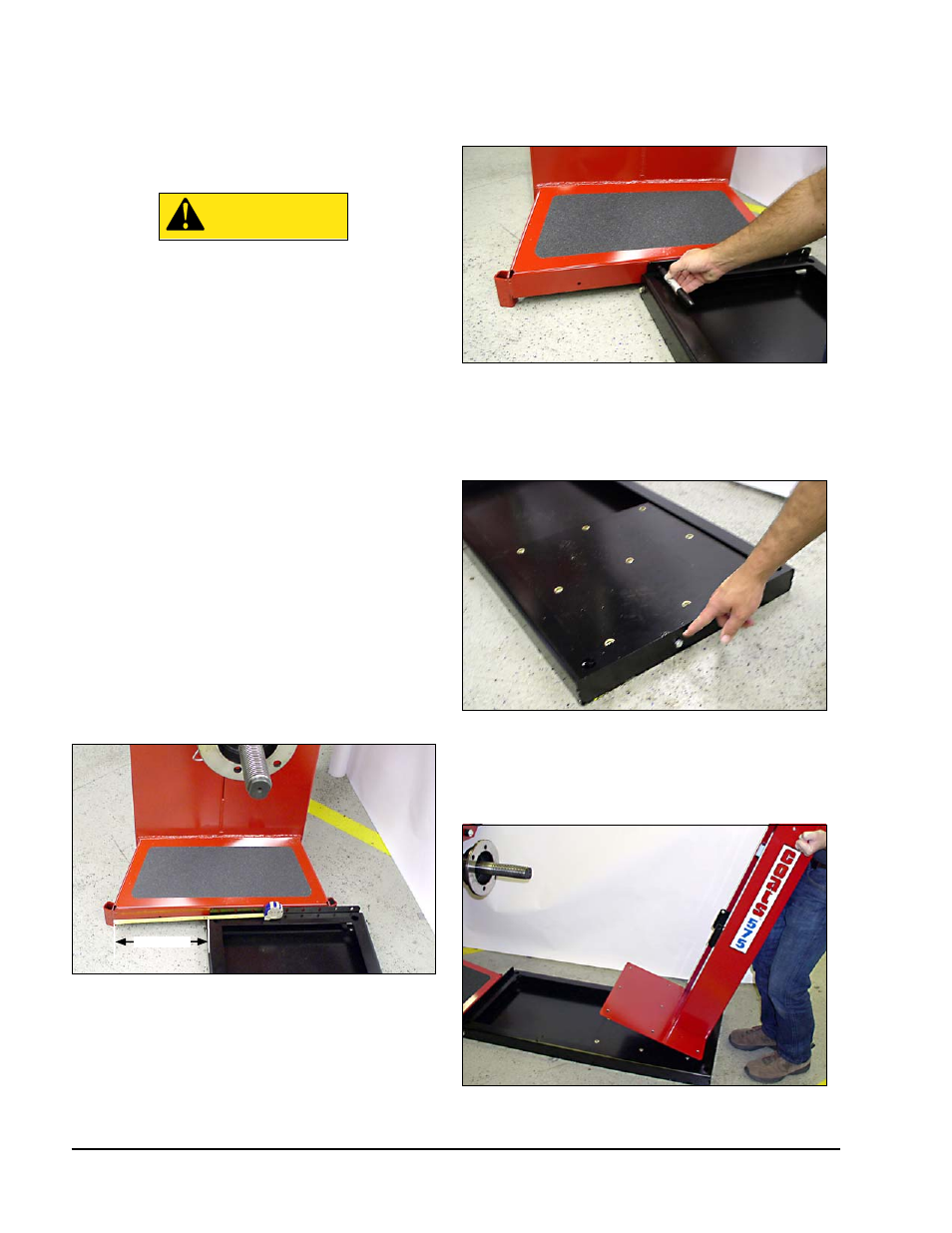

Position unit by your wheel balancer; then remove

BASE TRACK from pallet.

2.

Slide BASE TRACK so LIFT MOUNTING BRACKET

is up against the wheel balancer chassis; below the

stub shaft. With the aid of a tape measure, place the

BASE TRACK 12-inches from the balancer edge as

shown (fig 2).

Figure 2 - Position LIFT MOUNTING BRACKET Against Wheel

Balancer

3.

Mark two hole locations and use a size F (0.257")

or size G (0.261") drill bit to the drill holes. Choose the

LIFT MOUNTING BRACKET fastener hole locations

that are farthest apart from each other.

Figure 3 - Mark two drill hole locations

4.

Fasten base tray to balancer using two self-

tapping bolts.

5.

Remove and discard the shipping bolt at the end

of the BASE TRACK.

Figure 4 - Remove Shipping Bolt Holding CARRIAGE INSERT

6.

Remove pivot bolt from WHEEL TRAY and set

WHEEL TRAY and pin aside.

7.

Now place the TOWER ASSEMBLY on the CAR-

RIAGE INSERT as shown.

Figure 5 - Position TOWER ASSEMBLY on CARRIAGE INSERT

12-inches