Warning, Operation – COATS 550 Heavy Duty Tire Lift User Manual

Page 5

COATS Heavy Duty Lift • 5

4.

Locate storage tower and hardware. Stand stor-

age tower up and assemble it to the frame using the

hardware (Fig. G).

5.

Locate wheel ramp and hardware. Attach wheel

ramp to lift assembly as shown (Fig. G).

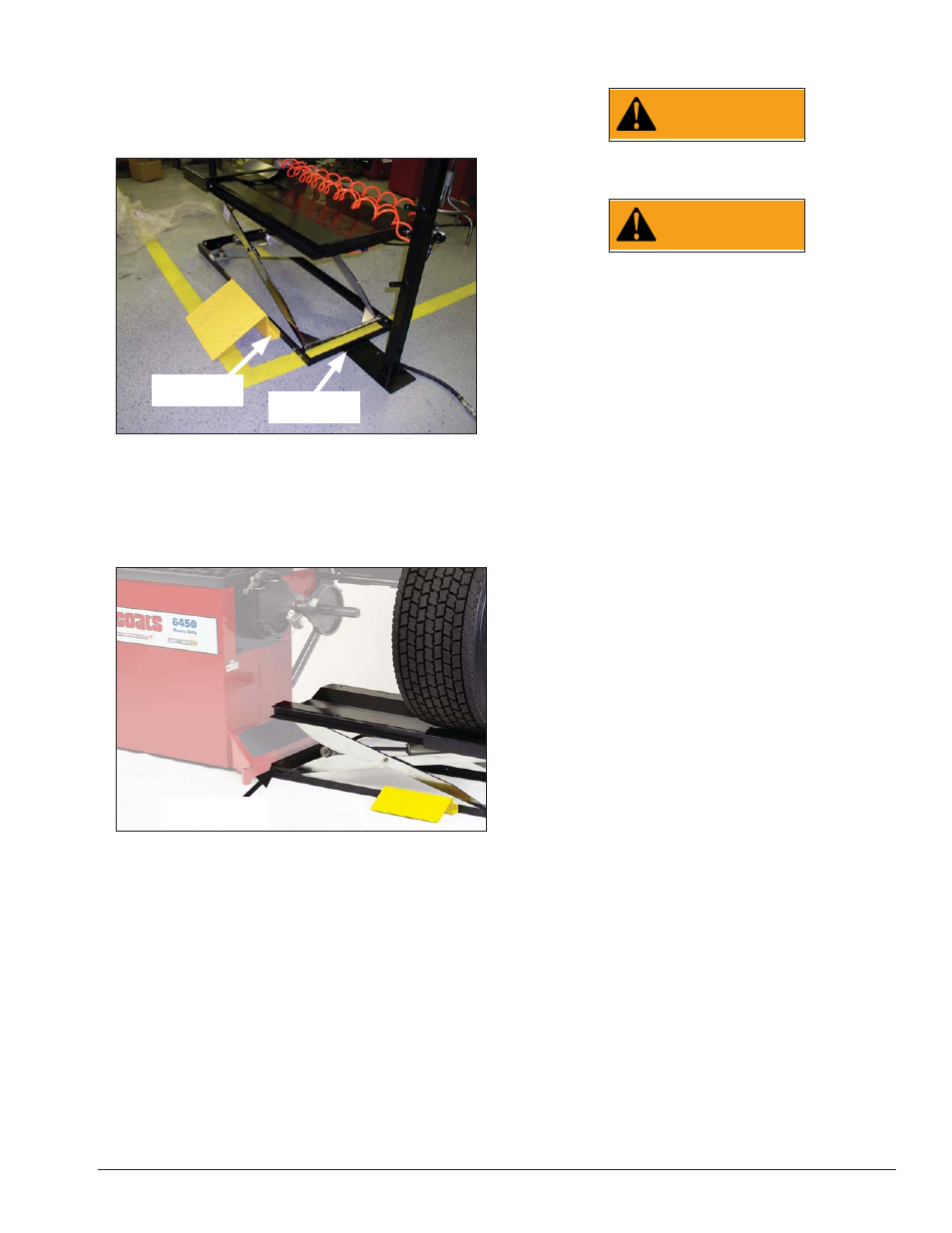

Figure G - Fasten Tower and Wheel Ramp to Lift Assembly

6.

Fasten lift to balancer (Fig. H). Position lift against

the wheel balancer; aligning the two holes on the plate

with the two holes on the balancer. Secure using (2)

3/8-16 x 1-1/2 HHCS screws, (4) 3/8 plain washers and

(2) 3/8-16 Nyloc hex lock nuts.

Figure H - Fasten Heavy Duty Lift Assembly to COATS®

Wheel Balancer

Note: The COATS 6401 wheel balancer requires the

550 Heavy Duty Lift Adapter Kit 85607401 to attach the

lift to the wheel balancer.

Pneumatic Connection

Connect air intake to a compressed air system with

a working pressure of 120-150 PSI. Use a compressed

air hose with an inside diameter of 1/4” - 3/8”.

Important: Make sure the air hose is free of the track

area. If the air hose is damaged, the lift may descend

unexpectedly.

Operation

WARNING

Before moving the carriage, make sure the

track area is clear of debris.

WARNING

Do not put your hands on the top of the

wheel, during this operation. Your hand

could be pinched between the wheel and

the carriage handle.

550 Heavy Duty Lift Operation

1.

Use carriage handle to slide the carriage back away

from the balancer; aligning it with the wheel ramp.

2.

Push the valve handle downward; making sure the

carriage assembly is completely lowered.

3.

Roll the wheel assembly over the wheel ramp to

load it onto the carriage.

4.

Push the valve handle upward to raise the wheel

assembly; centering it with the balancer stub shaft.

5.

Use the carriage handle to slide the carriage for-

ward until the wheel assembly is on the balancer stub

shaft; ready to be mounted on the balancer.

6.

Secure the wheel to the balancer using suitable

mounting adapters.

7.

Push the valve handle downward so the carriage

no longer contacts the wheel assembly.

8.

Move the carriage back out of the wheel balancer

work area.

9.

Balance the wheel.

10.

Use the carriage handle to move the carriage

forward; under the wheel assembly.

11.

Push the valve handle upward so the carriage

will support the wheel assembly.

12.

Remove the wheel assembly from the balancer

stub shaft.

13.

Use the carriage handle to slide the carriage

back away from the balancer; aligning it with the wheel

ramp.

14.

Push the valve handle downward; making sure

the carriage assembly is completely lowered.

15.

Unload the wheel assembly by rolling it out of

the carriage and down the wheel ramp.

Fasten Wheel

Ramp to Lift

Fasten Tower

to Lift

Fasten Lift to

Wheel Balancer