Pressure indicator calibration – BAND-IT S100 Classic Air Tool User Manual

Page 8

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

Document # P09287 rev. L

© Copyright

BAND-IT-IDEX, Inc. 2006

All rights reserved

www.BAND-IT-IDEX.com

Page 8 of 18

S10099

Classic Air Tool

Pressure Indicator

Calibration

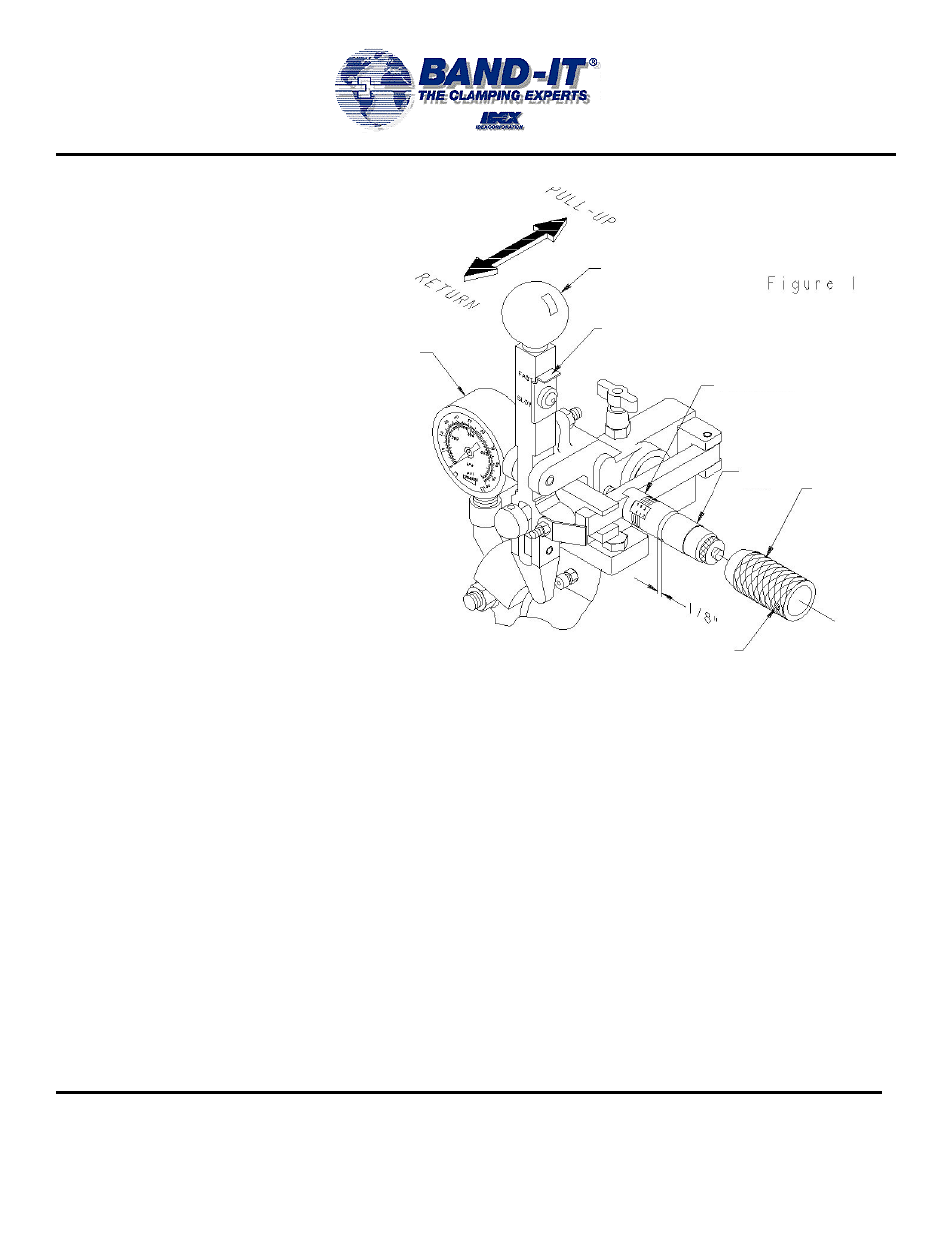

Figure 1

CALIBRATION PROCEDURE

:

REFER TO FIGURE 1 FOR IDENTIFICATION OF EACH PART.

LOOSEN SET SCREW AND REMOVE PRESSURE INDICATOR SLEEVE.

TURN ADJUSTING KNOB CLOCKWISE UNTIL THERE IS A 1/8” GAP BETWEEN ADJUSTING KNOB AND INDICATOR AS SHOWN.

ACTUATE VALVE HANDLE TO THE PULL-UP CYCLE AND OBSERVE PRESSURE GAUGE. PRESSURE SHOULD STOP INCREASING

AT 70 PSI.

PULL VALVE HANDLE BACK TO RETURN CYCLE, TURN ADJUSTING KNOB CLOCKWISE OR COUNTERCLOCKWISE TO FINE TUNE

PRESSURE GAUGE TO 70 PSI. (BE SURE TO PULL VALVE HANDLE BACK TO ITS RETURN CYCLE POSITION BEFORE EACH

ADJUSTMENT IS MADE).

SLIDE PRESSURE INDICATOR SLEEVE BACK OVER ADJUSTING KNOB AND INDICATOR. ALIGN TAPERED FRONT EDGE OF

PRESSURE INDICATOR SLEEVE WITHIN THE NUMBER SEVEN (7) GROOVE AND LOCK IT IN PLACE WITH SET SCREW.

ONCE INDICATOR SLEEVE HAS BEEN LOCKED IN PLACE TO ADJUSTING KNOB, BOTH PARTS CAN BE TURNED

COUNTERCLOCKWISE FOR LOWER PRESSURE SETTINGS OR CLOCKWISE TO INCREASE PRESSURE SETTING. WHEN

INCREASING PRESSURE, TURN KNOB PAST REQUIRED PRESSURE SETTING ONE (1) OR TWO (2) TURNS THEN BACK TO

REQUIRED PRESSURE SETTING.

80 PSI SETTING CAN BE ACCOMPLISHED BY TURNING INDICATOR SLEEVE CLOCKWISE ALL THE WAY UNTIL IT COMES TO A

STOP, THEN BACK OFF TWO COMPLETE TURNS.

SET SCREW

PRESSURE GAUGE

VALVE HANDLE

SLOW / FAST SELECTOR

ADJUSTING

KNOB

INDICATOR

PRESSURE

INDICATOR

SLEEVE

CALIBRATION SET-UP:

NUMBERS SHOWN ON INDICATOR ARE IN 10 PSI

GRADUATIONS.

EXAMPLE: 7 = 70 PSI 6 = 60 PSI

PRESSURE INDICATOR CALIBRATION SHOULD ALWAYS

BE DONE AT 70 PSI.

USE MIDWAY SPACE BETWEEN EACH GRADUATION

LINE FOR 5 PSI GRADUATION.

WHEN CALIBRATING OR ADJUSTING PRESSURE INDICATOR,

VALVE HANDLE MUST ALWAYS BE IN RETURN POSITION

(PISTON ROD FULLY EXTENDED TO THE FRONT).

SPEED CONTROL SELECTOR MUST BE SET ON “FAST” PULL-

UP PRIOR TO CALIBRATION (AS SHOWN).