Troubleshooting 6 – Echo 77412 Owners Manual v.3 User Manual

Page 28

Crary Bear Cat Owners Manual

26

Section

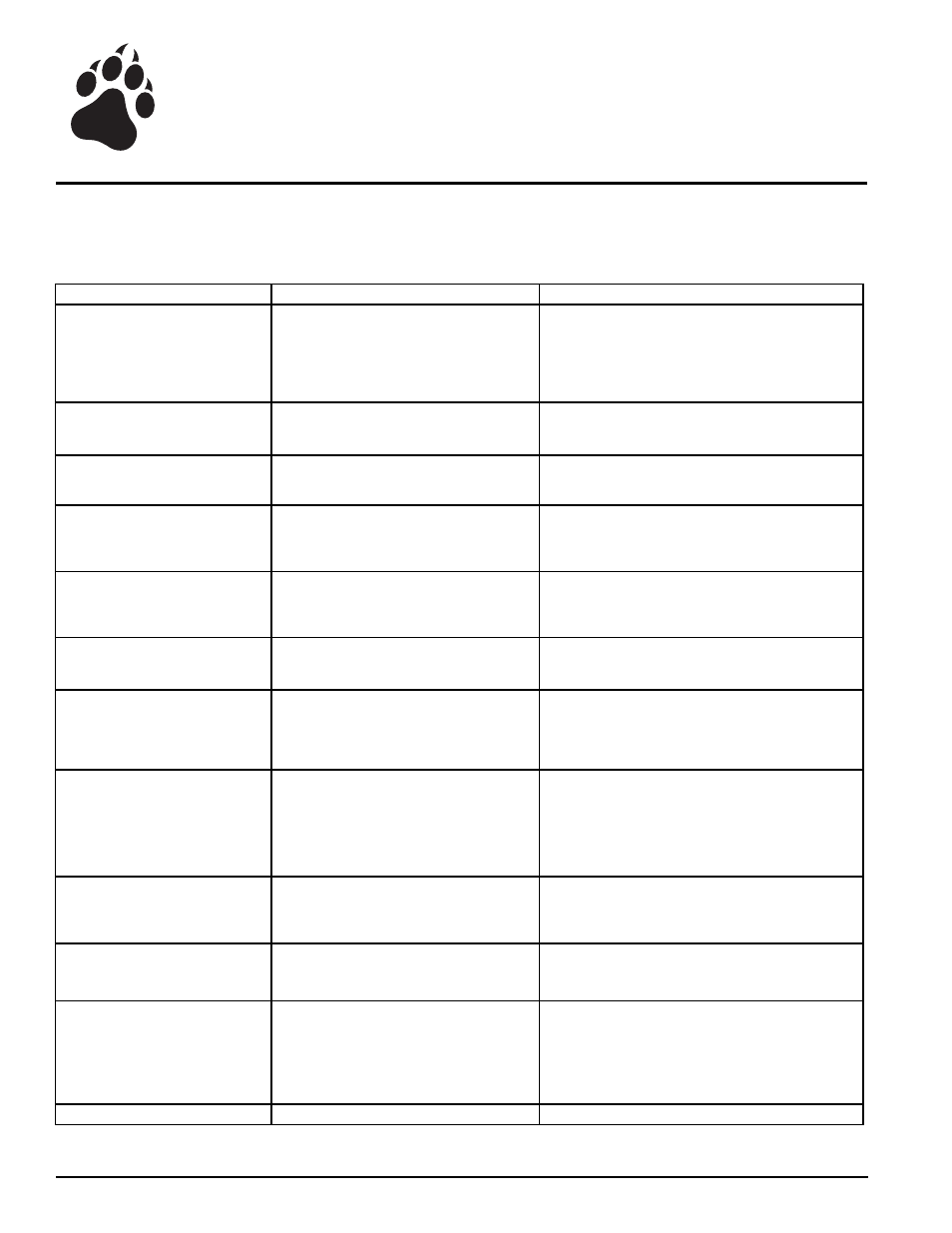

Before performing any of the corrections in this troubleshooting chart, refer to the appropriate information contained in this manual

for the correct safety precautions and operating or maintenance procedures. Contact your nearest dealer or the factory for service

problems with the machine.

PROBLEM

POSSIBLE CAUSE

REMEDY

Engine will not start.

Improper control settings.

Lack of fuel.

Spark plug disconnected.

Dirty, stale or contaminated gas.

Internal engine problems.

1.

2.

3.

4.

5.

Use proper settings.

Fill fuel tank.

Connect spark plug.

Refill gas tank with fresh, clean unleaded regular gaso-

line.

See your dealer.

1.

2.

3.

4.

5.

Engine or rotor stalls or stops.

Obstructed discharge.

Plugged rotor.

Feeding material too large into shredder.

1.

2.

3.

Use branch or similar object to clear discharge.

Clear rotor. Feed material more evenly.

Reduce size of material being fed into shredder.

1.

2.

3.

Engine overheats.

Cooling system plugged.

Improper oil level.

1.

2.

Clean cooling fan and fins.

Fill engine to correct oil level. Refer to the engine own-

ers manual.

1.

2.

Hard to feed chipper; requires

excessive power to chip.

Dull chipper blades.

Obstructed discharge.

Improper blade clearance.

1.

2.

3.

Reverse or sharpen blades.

Use branch or similar object to clear discharge.

Adjust clearance between chipper block and chipper

blades.

1.

2.

3.

Shredder requires excessive

power or stalls.

Obstructed discharge.

Plugged rotor.

Wet or green material will not discharge.

1.

2.

3.

Use branch or similar object to clear discharge.

Clear rotor, feed material into shredder more evenly.

Alternately feed dry material or install larger discharge

screen.

1.

2.

3.

Engine stalls or belt squeals

when engaging clutch.

Engaging clutch too fast.

Plugged rotor.

Belt tension too loose.

1.

2.

3.

Lower engagement handle more slowly.

Clear rotor. Feed material more evenly.

Replace belt or spring.

1.

2.

3.

Material from chipper wraps

around rotor shaft.

Stringy, green material bypasses chipper

blades.

Dull chipper blades.

Improper blades clearance.

1.

2.

3.

Rotate branch or material when feeding to cut com-

pletely.

Sharpen blades.

Adjust clearance between chipper block and chipper

blades.

1.

2.

3.

Excessive vibration while running.

Drive system vibration.

Rotor out of balance.

Chipper blade to chipper block clearance is

incorrect.

1.

2.

3.

Check drive belts and pulleys for bad or worn areas. Check

for dull chipper blades or shredder knives.

Inspect rotor for broken or missing chipper blades and

shredder knives; replace if needed. Check rotor to see if

it wobbles. Check to see if rotor is assembled correctly.

Set chipper blade/block clearance to recommended dis-

tance (1/16" to 1/8").

1.

2.

3.

Rotor will not turn.

Drive belt too loose or broken.

Obstructed discharge.

Plugged rotor.

1.

2.

3.

Replace belt or spring.

Use branch or similar object to clear discharge.

Clear rotor. Feed material more evenly.

1.

2.

3.

Cannot engage clutch.

Improper belt installation; belt not under belt

guide.

Improper belt tension.

1.

2.

Install belt properly; install belt under belt guide.

Replace belt or spring.

1.

2.

Excessive belt wear.

Not using correct belt.

Pulley(s) damaged or worn.

Pulley(s) not in alignment.

Belt(s) tension too loose.

1.

2.

3.

4.

Contact your nearest authorized dealer to order the correct

belt for your chipper.

Replace pulley(s).

Align pulley(s) with straight edge.

Replace belt or spring.

1.

2.

3.

4.

Trailer sways during towing.

Tire air pressure not correct

1.

Check tire sidewall for inflation limits.

1.

Troubleshooting

6