Warning – Echo 77412 Owners Manual v.3 User Manual

Page 21

Crary Bear Cat Owners Manual

19

SERVICE & MAINTENANCE

BEFORE INSPECTING OR SERVICING ANY PART OF THIS MACHINE, SHUT OFF POWER SOURCE,

DISCONNECT SPARK PLUG WIRE FROM SPARK PLUG AND MAKE SURE ALL MOVING PARTS HAVE COME TO A COMPLETE STOP.

WARNING

5.3.3 INSTALLING THE BLADES

Lock disk assembly (Section 5.2).

Place a blade on the disk and attach using two 1/2" x 1-3/4"

flat head screws and two 1/2" security lock nuts. Torque the

1/2" security lock nuts to 120 Ft.-lb. Repeat for the remain-

ing blades.

Reinstall the chipper deflector (Section 2.3).

1.

2.

3.

5.3.2 SHARPENING THE BLADES

Never sharpen or grind the mounting surfaces of the blades.

This will cause the edge to roll and the blade will be dam-

aged, resulting in poor chipping performance.

Regrind the angled edge of the chipping blades to 45 de-

grees (Figure 5.3).

The blades can be ground on a bench grinder or by a pro-

fessional.

Make sure some type of fixture is used to correctly hold the

blade at the proper angle.

Be careful when grinding so that the blade does not become

overheated and change color. This will remove the heat-

treated properties.

Use short grinding times and cool with water or some type

of liquid coolant.

Remove an equal amount off each blade to maintain rotor

balance.

Small imperfections such as nicks and burrs on the flat side

of the blade will not affect the chipping performance of the

machine.

For blades that have been repeatedly sharpened, ensure

that the sharpened surface extends past the chipping slot

opening. If it does not extend past the opening, the blades

should be replaced.

1.

2.

3.

4.

5.

6.

7.

8.

9.

5 . 4 S E T T I N G C H I P P I N G B L A D E

CLEARANCE

The chipping blades should clear the chipping anvil, located

directly under the chipper chute, by least 1/16 inch. To adjust

the blade clearance, proceed as follows:

Removing the chipper chute is NOT required for setting the

chipping blade clearance, although, removing the chipper

chute can provide better access for measuring the chipping

blade clearance.

Rotate the disk until a chipping blade is even with the chip-

ping anvil.

Measure the amount of clearance between the chipping

blade and chipper anvil from inside of the chipper housing.

The minimum distance between the chipping blade and the

chipping anvil should be 1/16"

Adjust the anvil by loosening the 5/16" x 5/8" bolts hold-

ing the anvil to the disk cover and sliding the anvil inward

or outward until the desired measurement is achieved.

NOTE: If the chipping anvil edge is damaged or worn un-

evenly, remove the three 5/16" bolts and washers holding

the anvil to the disk cover and use one of the other three

edges. Adjust for correct measurement.

Tighten the bolts and torque to 17 Ft-lbs.

Reinstall the chipper chute.

1.

2.

3.

4.

5.

6.

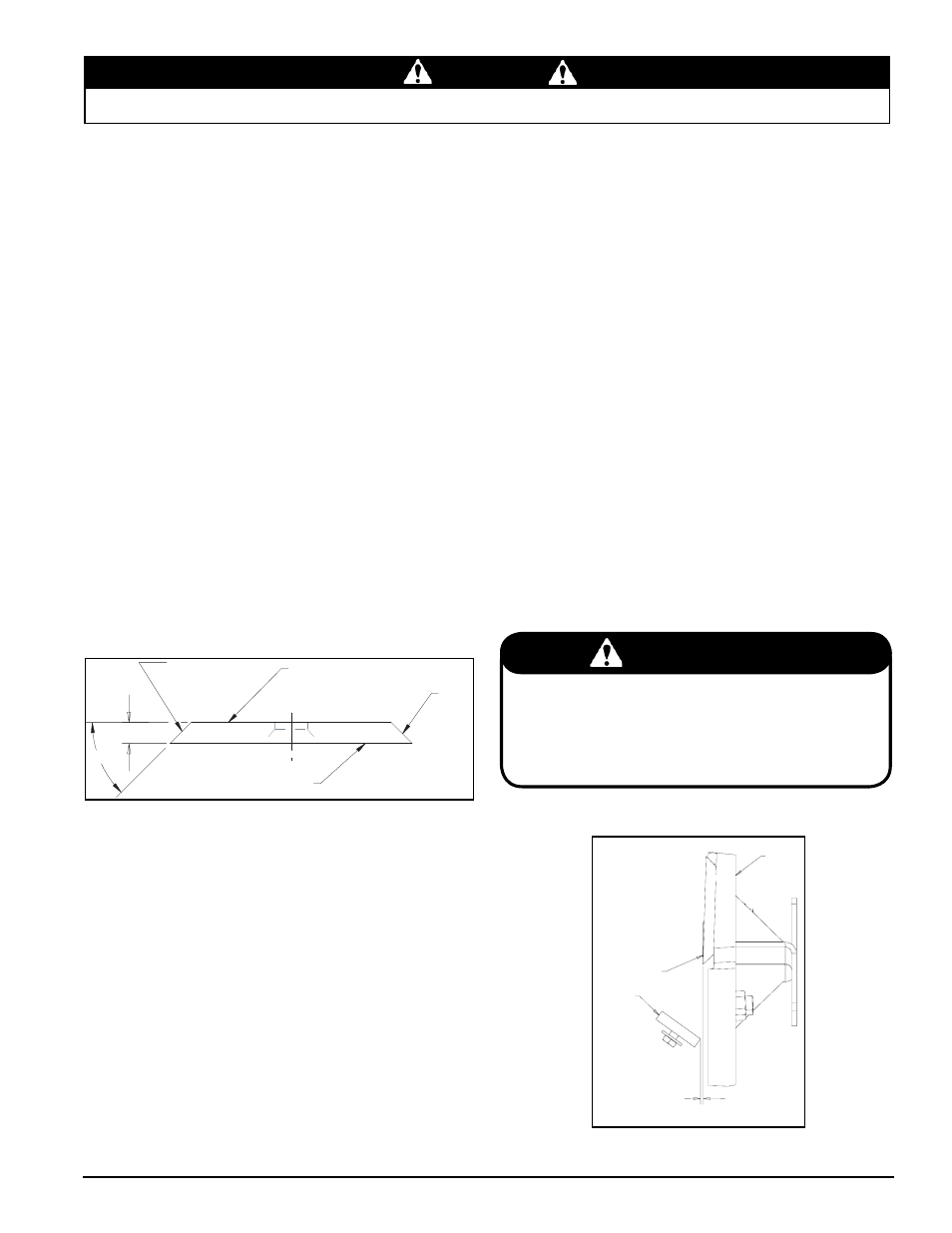

Figure 5.3 - Double Edged Blade

MOUNTING SURFACE

DO NOT GRIND

MOUNTING SURFACE

DO NOT GRIND

SHARPENED

SURFACE

SHARPENED

SURFACE

45˚

.38

1/16"

DISK

CHIPPER BLADE

ANVIL

Figure 5.4 - Chipper Blade and Anvil Clearance

WARNING

It is important to ensure that the minimum gap between the

chipping anvil and ALL chipping blades is 1/16". All chipping

blades should be rotated until even with the chipping anvil

and then measured. Failure to do so can result in the

chipping blades striking the chipping anvil. Causing serious

injury or death.