Oscillating axle lockout test, 3 free wheeling option, Oscillating axle lockout test -3 – JLG 800A_AJ ANSI Service Manual User Manual

Page 59: Free wheeling option -3

SECTION 3 - CHASSIS & TURNTABLE

3120740

– JLG Lift –

3-3

Oscillating Axle Lockout Test

LOCKOUT SYSTEM TEST MUST BE PERFORMED QUARTERLY,

ANY TIME A SYSTEM COMPONENT IS REPLACED, OR WHEN

IMPROPER SYSTEM OPERATION IS SUSPECTED.

NOTE: Ensure boom is fully retracted, lowered, and cen-

tered between drive wheels prior to beginning lock-

out cylinder test.

1. Place a 6 inch (15.2 cm) high block with ascension

ramp in front of left front wheel.

2. From platform control station, activate machine

hydraulic system.

3. Place FUNCTION SPEED CONTROL and DRIVE

SPEED/TORQUE SELECT control switches to their

respective LOW positions.

4. Place DRIVE control lever to FORWARD position

and carefully drive machine up ascension ramp until

left front wheel is on top of block.

5. Carefully activate SWING control lever and position

boom over right side of machine.

6. With boom over right side of machine, place DRIVE

control lever to REVERSE and drive machine off of

block and ramp.

7. Have an assistant check to see that left front wheel

remains locked in position off of ground.

8. Carefully activate SWING control lever and return

boom to stowed position (centered between drive

wheels). When boom reaches center, stowed posi-

tion, lockout cylinders should release and allow

wheel to rest on ground, it may be necessary acti-

vate DRIVE to release cylinders.

9. Place the 6 inch (15.2 cm) high block with ascension

ramp in front of right front wheel.

10. Place DRIVE control lever to FORWARD and care-

fully drive machine up ascension ramp until right

front wheel is on top of block.

11. Carefully activate SWING control lever and position

boom over left side of machine.

12. With boom over left side of machine, place DRIVE

control lever to REVERSE and drive machine off of

block and ramp.

13. Have an assistant check to see that right front wheel

remains locked in position off of ground.

14. Carefully activate SWING control lever and return

boom to stowed position (centered between drive

wheels). When boom reaches center, stowed posi-

tion, lockout cylinders should release and allow

wheel to rest on ground, it may be necessary acti-

vate DRIVE to release cylinders.

15. If lockout cylinders do not function properly, have

qualified personnel correct the malfunction prior to

any further operation.

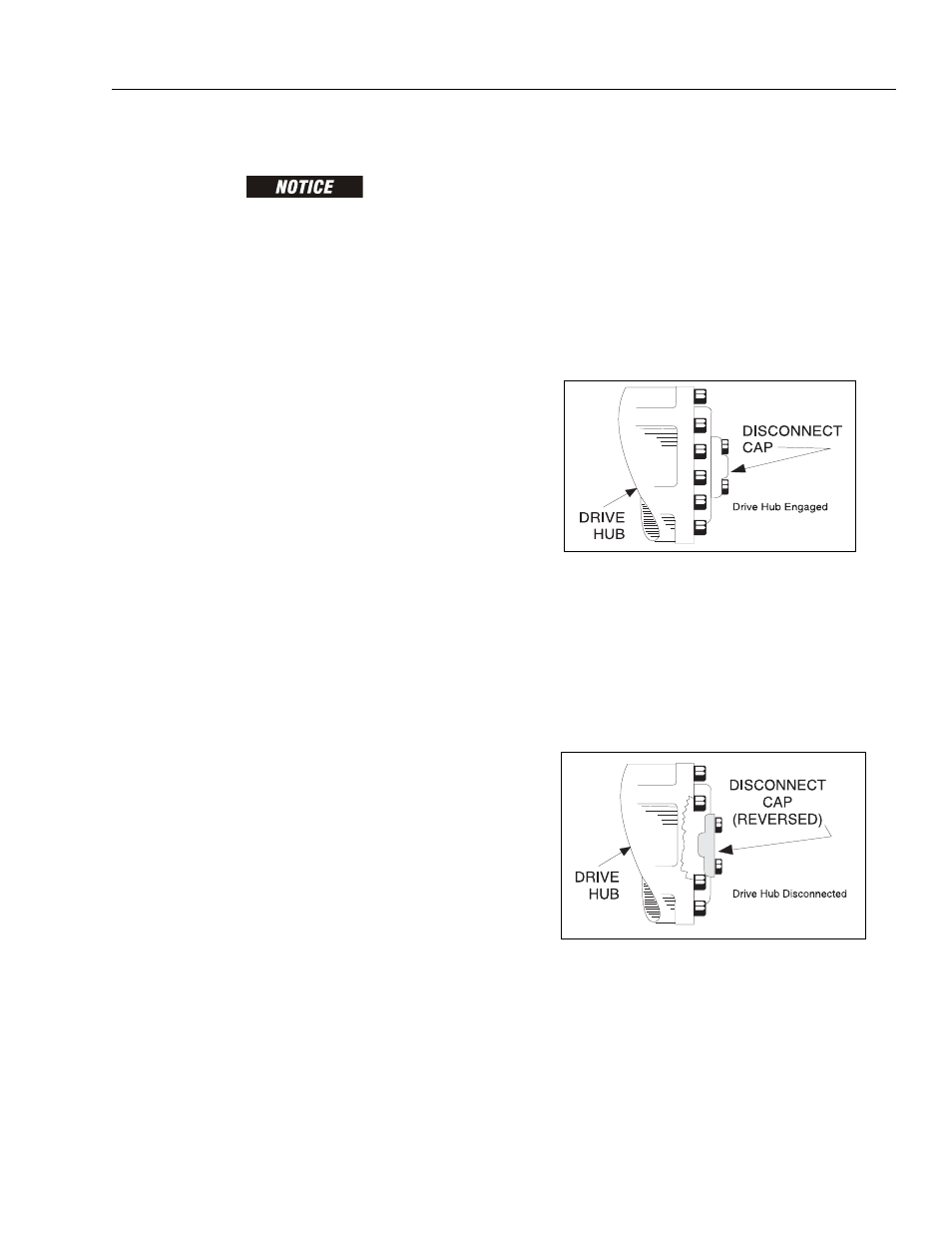

3.3 FREE WHEELING OPTION

To Disengage Drive Motors and Brakes (Free

Wheel) for Emergency Towing

1. Chock wheels securely if not on flat level surface.

2. Disconnect both drive hubs by reversing the discon-

nect caps in the center of the hubs.

To Engage Drive Motors and Brakes (Normal

Operation)

1. If equipped, move steer/tow valve to steer position

by pushing valve knob in.

2. Connect both drive hubs by inverting disconnect

cap in center of hub.

3. Remove chocks from wheels as required.