Lockout cylinder bleeding, Lockout cylinder bleeding -2, Oscillating valve adjustment -2 – JLG 800A_AJ ANSI Service Manual User Manual

Page 58: Brake valve wiring connection -2, Wheel torque chart -2

SECTION 3 - CHASSIS & TURNTABLE

3-2

– JLG Lift –

3120740

3. The tightening of the nuts should be done in stages.

Following the recommended sequence, tighten nuts

per wheel torque chart.

4. Wheel nuts should be torqued after first 50 hours of

operation and after each wheel removal. Check

torque every 3 months or 150 hours of operation.

3.2 OSCILLATING AXLE BLEEDING

PROCEDURE AND LOCKOUT TEST

Lockout Cylinder Bleeding

To start the test, the axle must be fully oscillated in one

direction. Start with oscillating the axle so that the left lock-

out cyl. is fully retracted (left front tire up), and the right

lock-out cyl. Is fully extended (right front tire down).

ENSURE PLATFORM IS FULLY LOWERED AND BOOM IS CEN-

TERED OVER REAR AXLE PRIOR TO BEGINNING BLEEDING PRO-

CEDURE. MAKING SURE MACHINE IS ON A LEVEL SURFACE AND

REAR WHEELS ARE BLOCKED, BRAKE WIRE IS DISCONNECTED.

1. Making sure machine is on a level surface and rear

wheels are blocked, brake wire is disconnected.

2. Center boom over rear axle making sure that cam

valve is depressed.

NOTE: To oscillate the axle, the lock-out valve plunger must

be depressed.

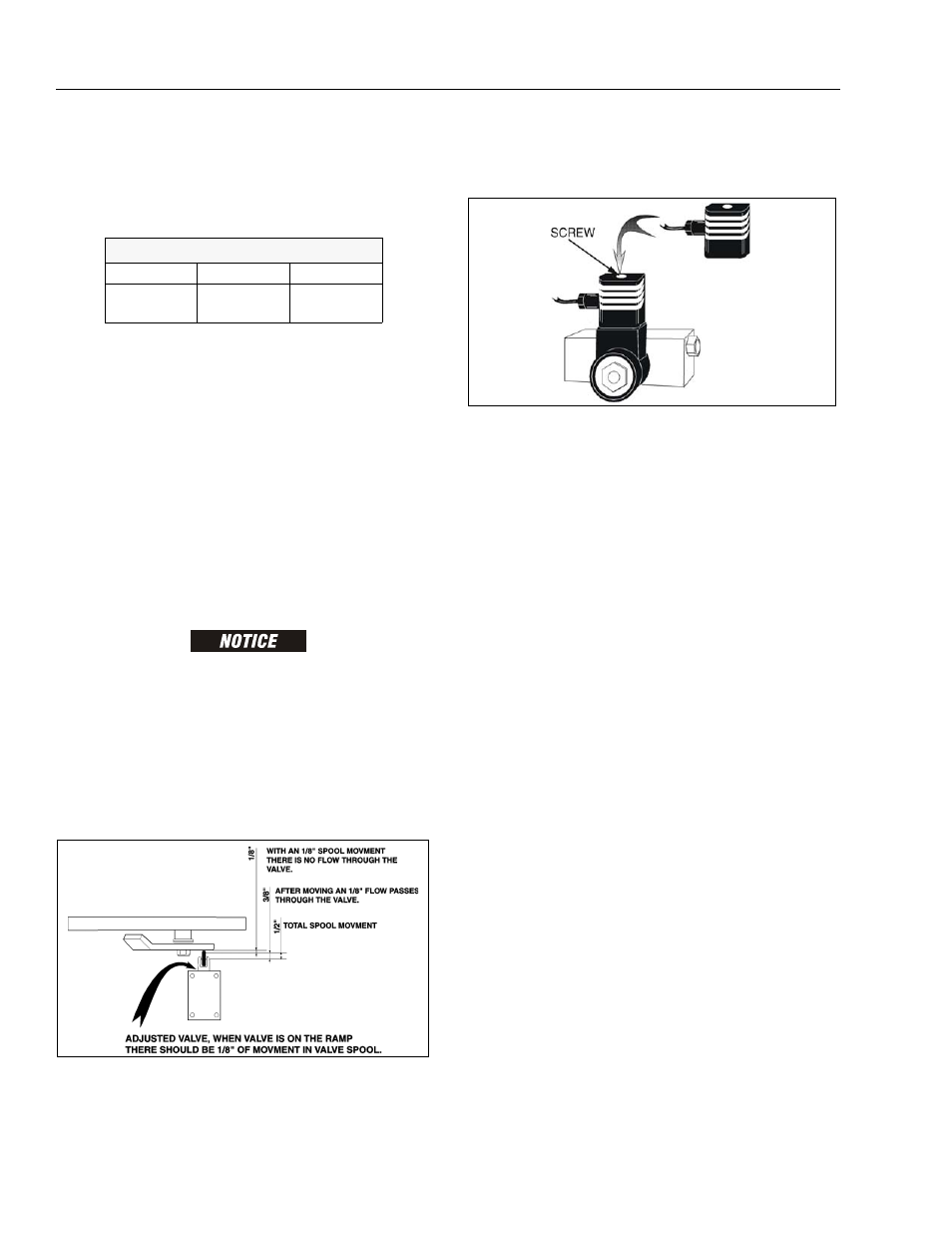

3. Using a Phillips screwdriver, remove screw from

connection on the brake valve and remove connec-

tor as shown.

4. Use suitable container to retain any residual hydrau-

lic fluid, place container under the lockout cylinder.

5. With the left lock-out cyl. retracted, open the bleeder

on top of the cylinder, then have an operator from

the platform (on high engine) feather drive. Activate

drive just enough so the engine is under load but

not enough to stall the engine.

6. Close the bleeder when there is a steady stream of

oil and not air.

7. With the axle in the same position, go to the right

lock-out cyl. and open the bleeder at the rod end.

Activate drive in the same manner and close when

all air has been purged.

8. Close the bleeder when there is a steady stream of

oil and not air.

9. Oscillate the axle the other direction, left lock-out cyl.

extended (tire down), right lock-out cyl. retracted

(tire up). Use the same procedure for the bleeder in

the rod end of the left lock-out cyl., Then the piston

end of the right lock-out cyl. then close.

10. Repeat this process one more time to ensure that all

air has been purged from the system.

11. Perform oscillating axle lockout test.

12. If necessary, repeat steps 1 thru 9.

13. Reinstall the brake wires. See Figure 3-2.

NOTE: Bleeding of the oscillating axles is an infrequent

operation performed after hydraulic line failure and or

lock-out cylinder repair.

Table 3-1. Wheel Torque Chart

TORQUE SEQUENCE

1st Stage

2nd Stage

3rd Stage

70 ft. lbs.

(95 Nm)

170 ft. lbs.

(225 Nm)

300 ft. lbs.

(405 Nm)

Figure 3-1. Oscillating Valve Adjustment.

Figure 3-2. Brake Valve Wiring Connection.