Load sensing control adjustment -30, Pressure compensation control adjustment -30 – JLG 800A_AJ ANSI Service Manual User Manual

Page 310

SECTION 5 - HYDRAULICS

5-30

– JLG Lift –

3120740

MACHINES S/N 0300121643 TO PRESENT

1. Set Stand by pressure or load sense pressure.

a. Install a low pressure gauge at port “MP” of the

main valve block. A gauge capable of reading

400 psi.

b. Remove the wires from the upper lift (main lift),

valve coils on the main valve block. Start the

engine and activate upper lift up or down. Hold

the function for 10-15 seconds. This bleeds the

air out of the sense line. The gauge should be

reading 400 psi. (+40 -0 psi). To make an adjust-

ment to this pressure, go to the engine compart-

ment, locate the function pump.

c. There are (2) adjustments at the top of the

pump. They are located on the pump compen-

sator which has (4) bolts mounting it to the

pump. The stand by adjustment is at the top.

d. To adjust this, a 4 mm and 6 mm Allen wrench

will be needed. The adjustment screw is facing

the front of the pump, or toward the engine.

First, using the 4 mm wrench, loosen the set-

screw on the side of the compensator (facing

you) which is in line with the adjustment screw.

This is a jam nut screw which holds the main

adjustment from turning. Loosen it 1 turn. Then

using the 6 mm wrench adjust the main adjust-

ment clockwise to increase or counter-clockwise

to decrease. The pressure should read between

400-440 psi.

2. Set High pressure relief

a. Install a high pressure gauge at the “MP” port of

the main valve block.

b. Activate upper (main) telescope in. The gauge

should read 2600 psi.

c. To make an adjustment to this pressure, go back

to the engine compartment to the function

pump. The high pressure relief adjustment is the

lower one of the (2) on the compensator. To

adjust this, a 4 mm and 6 mm Allen wrench will

be needed. The adjustment screw is facing the

front of the pump, or toward the engine.

d. First, using the 4 mm wrench, loosen the set-

screw on the side of the compensator (facing

you) which is in line with the adjustment screw.

This is a jam nut screw which holds the main

adjustment from turning. Loosen it 1 turn.

e. Then using the 6 mm wrench adjust the main

adjustment clockwise to increase or counter-

clockwise to decrease. This is the maximum

relief pressure for all functions governed by this

pump.

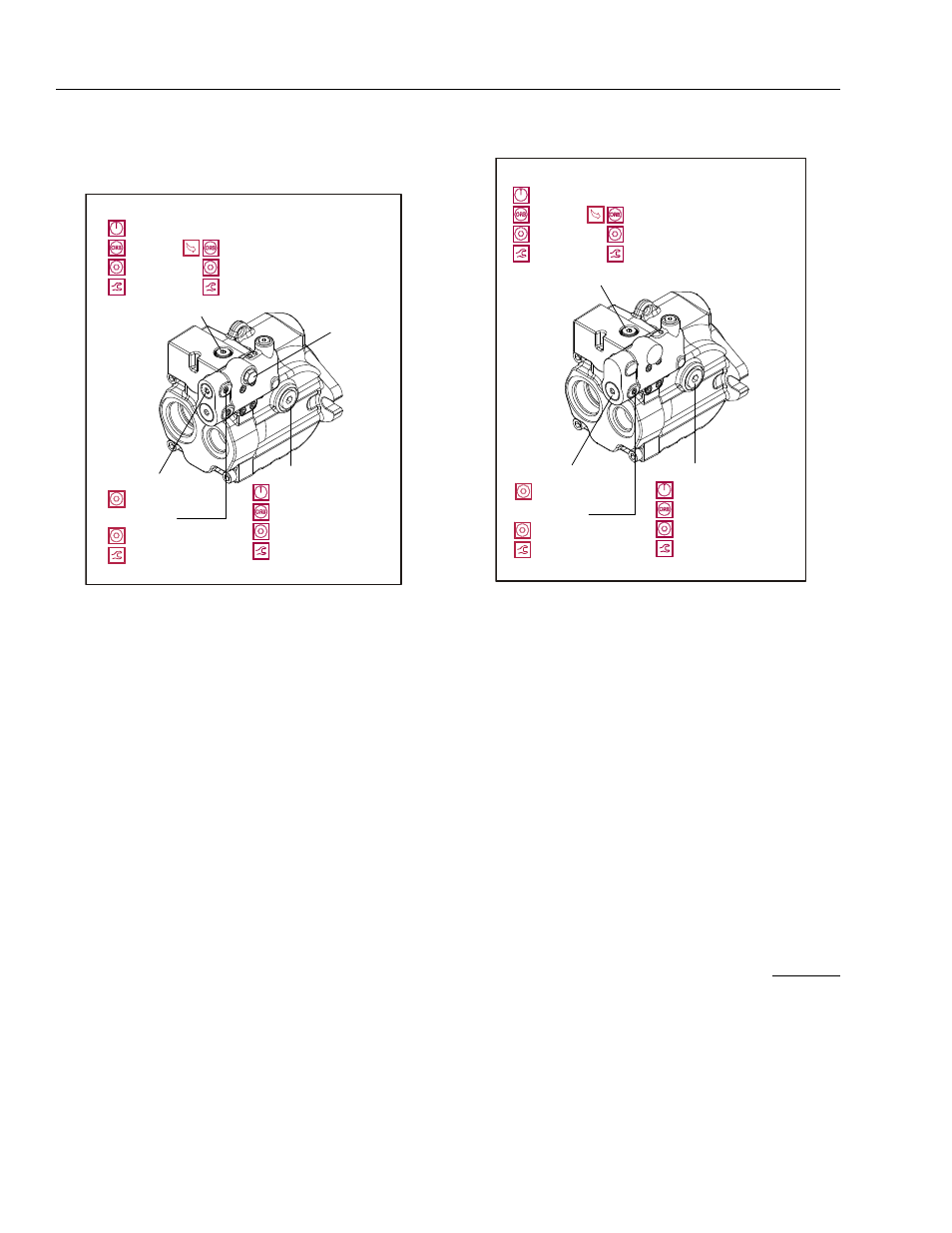

LS adjustment screw

6mm

LS set screw

4mm

7-11 N•m [6-8 lbf•ft]

Case drain port L1

0-10 bar [0-100 psi]

7/8-14

3/8 in

54-136 N•m

[40-100 lbf•ft]

Gauge port M2

0-300 bar [0-5000 psi]

9/16-18

1/4 in

34-68 N•m

[25-50 lbf•ft]

M14

6mm

27-35 N•m

[20-26 lbf•ft]

LS/remote PC

signal port X

Figure 5-25. Load Sensing Control Adjustment

PC adjustment screw

6mm

PC set screw

4mm

7-11 N•m [6-8 lbf•ft]

Case drain po

rt L1

0-10 bar [0-100 psi]

7/8-14

3/8 in

54-136 N•m

[40-100 lbf•f t]

Gauge port M2

0-300 bar [0-5000 psi]

9/16-18

1/4 in

34-68 N•m

[25-50 lbf•ft]

M14

6mm

27-35 N•m

[20-26 lbf•f t]

Figure 5-26. Pressure Compensation Control

Adjustment