Automatic choke adjustment procedure, General, Automatic choke adjustment procedure -113 – JLG 800A_AJ ANSI Service Manual User Manual

Page 169: General -113, Position controller truth table -113

SECTION 3 - CHASSIS & TURNTABLE

3120740

– JLG Lift –

3-113

d. Speed seems to slowly wander (5-15 second

periods) around at speed, particularly at higher

loads. See item 2a. 3 concerning excessive on

Governor.

(3.) Governor not tuned or adjusted for engine/applica-

tion.

The basic adjustment to set sensitivity/stability is the Gain

pot. A good starting point for many engines is full CCW,

then CW 1/3 turn. (See “Governor adjustment” section).

To increase stability, turn CCW. If satisfactory governing

cannot be achieved with this one adjustment, the factory

adjustment may be needed. Normal starting point for this

adjustment is fully CCW, then CW 1/4 turn. (Before chang-

ing this pot, mark the original position).

NOTE: If problems occurs with the Governor overshooting

when a large load is released from the engine, such

as driving up a hill and stopping. There is usually

one of two things:

a. Gain adjustment is to far CCW.

b. Mechanical preload between the carburetor and

actuator is to large, this should be no greater

than 1/2 to 1 ball dia. (Ref. to page 43 par. 1).

Automatic Choke Adjustment Procedure

(For all JLG 1.IL and 2.3L Ford carbureted engines)

1. At 70°F the choke plate should be open 1/3” (not

touching the choke bore).

2. If the ambient temperature is not 7o°F, an additional

adjustment is required:

a. Loosen the three cover plate screws.

b. Adjust the cover to open the choke plate 1/32”.

c. Readjust for ambient temperature by rotating the

cover one (1) mark per 5°F from 70°. Rotate

CCW (lean) if warmer than 70°, CW (rich) if

colder than 70°.

(If actual temperature is 80°, set at 1/32” and

rotate two (2) marks CCW (lean) direction.)

d. Tighten the three cover plate screws and check

for free rotation (no sticking or binding) of the

choke shaft.

3.27 THROTTLE CHECKS AND

ADJUSTMENTS - DEUTZ ENGINE

(PRIOR TO S/N 0300065534)

General

The throttle control system on the Deutz engine includes

the positional controller and the actuator.

Four LEDs are incorporated in the controller. They are as

follows:

• Red - failure: signals a problem with the system -

needs service or adjustment

• Green - clutch engaged; operation normal while sys-

tem is powered.

• Amber - motor extend

• Amber - motor retract

The controller is designed so that when the system volt-

age reaches 10.5 volts, the actuator clutch will be

released and the motor drive turned off in order to prevent

unpredictable operation from occurring.

When a failure condition occurs (i.e. position time-out) the

controller will release the clutch and turn off the actuator

motor. This will prevent unnecessary motor wear.

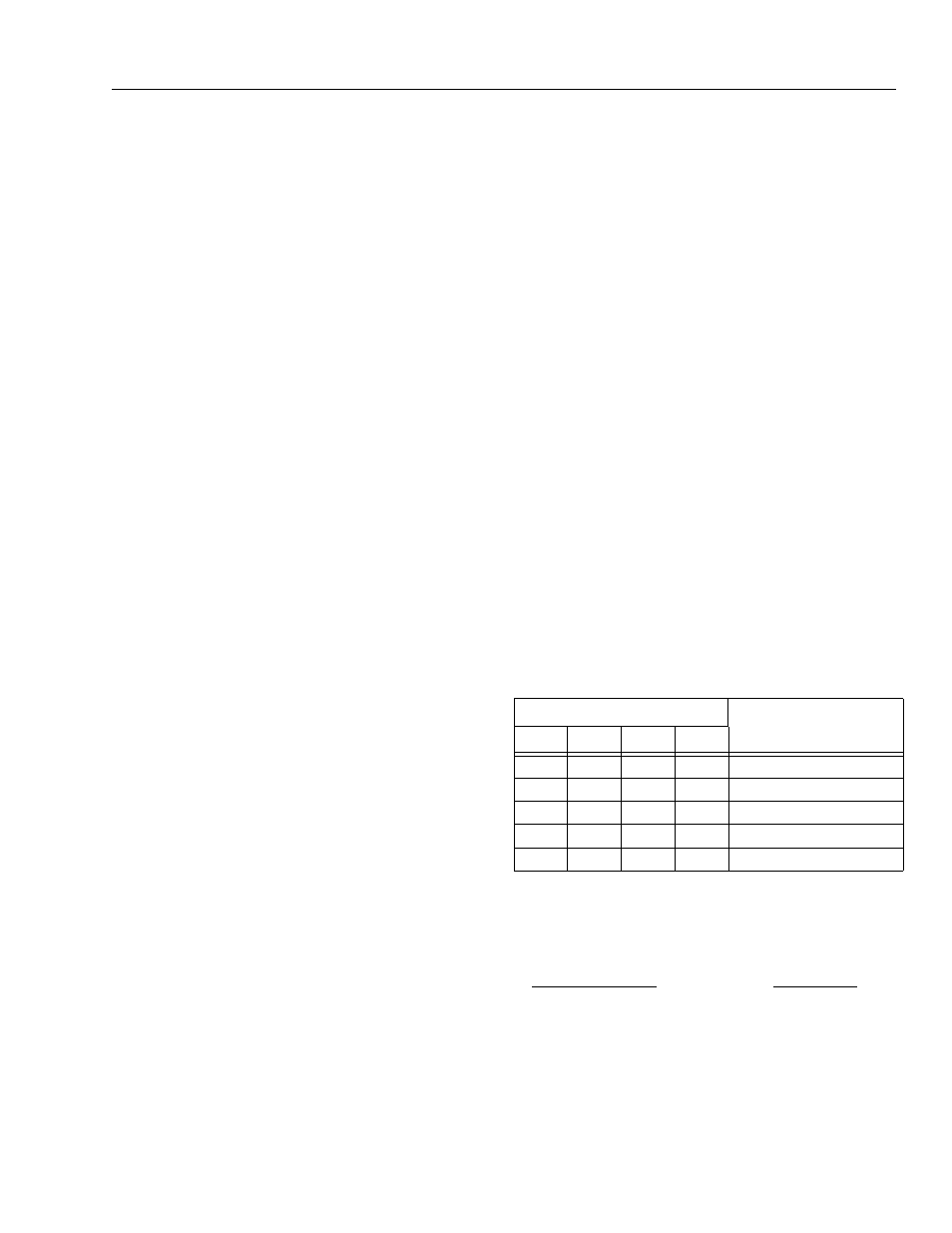

Table 3-11.Position Controller Truth Table

Control Wiring

Actuator Position

Black

Red

White

Green

GND

OFF

X

X

OFF POSITION (Freewheel)

GND

+12 VDC

OFF

OFF

POSITION 1 (See Adjustments)

GND

+12 VDC

+12 VDC

OFF

POSITION 2 (See Adjustments)

GND

+12 VDC

OFF

+12 VDC

POSITION 3 (See Adjustments)

GND

+12 VDC

+12 VDC

+12 VDC

POSITION 4 (See Adjustments)

GND = POWER SUPPLY OR BATTERY GROUND

OFF = GROUND OR OPEN CIRCUIT

X = DON’T CARE

+12 VDC = +12 VOLT POWER SUPPLY OR BATTERY SYSTEM, VIA A 5 AMP FUSE

OR CIRCUIT BREAKER

TRIMMER ADJUSTMENTS

LED INDICATORS

1 - POSITION 1 CW=RETRACT

2 - POSITION 2 CW=RETRACT

3 - POSITION 3 CW=RETRACT

4 - POSITION 4 CW=RETRACT

R - RETRACT INDICATOR (AMBER)

E - EXTEND INDICATOR (AMBER)

C - CLUTCH INDICATOR (GREEN)

F - FAILURE INDICATOR (RED)